Abstract

Oxidation kinetics for the intermetallic Ni3Ta in air at 600–1000°C are studied by a thermogravimetric method. The alloy has an ordered crystal structure (D13 2h-Pmmn) with rhombic lattice parameters a=0.512 nm, b=0.423 nm, and c=0.452 nm. The kinetic isotherms of Ni3Ta oxidation are described by a parabolic equation. With t≤800°C there is a periodic increase in the rate constant of parabolic oxidation, but with t>800°C there is a periodic decrease of it. In the range 850–875°C the alloy oxidation rate decreases as a result of scale sintering. Oxygen diffusion slows down in the compact scale. X-ray and metallographic analysis of the scale that forms on Ni3Ta indicates that it contains NiO, NiO·Ta2O5, Ta2O5 and also Ni and the solid solution Ni(Ta). These phase components are distributed in layers of the scale: NiO (first), NiO+NiO·Ta2O5 (second), NiO·Ta2O5+Ni+Ta2O5 (third), Ta2O5+Ni(Ta) (fourth). With a low temperature and short periods of heating there is no Nio·Ta2O5 or Ni(Ta) in the scale. Oxidation of Ni3Ta is controlled by oxygen diffusion in the scale over the direction towards the alloy. With t>850°C this mechanism changes. By analogy with oxidation of tantalum it is assumed that structural changes in the Ta2O5 lattice may be responsible for this.

Similar content being viewed by others

References

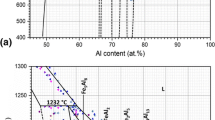

I. I. Kornilov and E. N. Pylaeva, “Phase-equilibrium diagram of the tantalum—nickel, system,”Zh. Neorg. Khim.,7, No. 3, 590–595 (1962).

E. N. Pylaeva, E. I. Gladyshevskii, and P. I. Kripyakevich, “Crystal structure of the compounds Ni3Nb and Ni3Ta,”Zh. Neorg. Khim.,3, No. 7, 1626–1631 (1958).

Index to the X-Ray Powder Data Film, Amer. Soc., Test Mat., Philadelphia (1972).

V. I. Mikheev,X-Ray Guide for Minerals [in Russian], Geoltekhizdat, Moscow (1957).

L. I. Mirkin,Handbook for x-Ray Analysis of Polycrystals [in Russian], Fizmatgiz, Moscow (1961).

I. M. Frantsevich, R. F. Voitovich, and V. A. Lavrenko,High-Temperature Oxidation of Metals and Alloys [in Russian] Izd. Tekh. Lit., Kiev (1963).

G. V. Samsonov (ed.),Physicochemical Properties of Alloys: Handbook [in Russian], Metallurgiya, Moscow (1978).

G. V. Samsonov (ed.),Properties of Elements: Handbook, Vol. 1 [in Russian], Metallurgiya, Moscow (1976).

O. Kubashevsky and B. Hopkins,Oxidation of Metals and Alloys [Russian translation], Izd. Inostr. Lit., Moscow (1955).

P. Kofstad,High-Temperature Oxidation of Metals [Russian translation], Mir, Moscow (1969).

P. Kofstad, “The oxidation behavior of tantalum at 700–1000°C,”J. Electrochem. Soc.,110, No. 6, 491–501 (1963).

Additional information

Institute for Problems of Materials Science, Ukraine National Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 3–4(406), pp. 80–87, March–April, 1999.

Rights and permissions

About this article

Cite this article

Chuprina, V.G. Oxidation of alloys of the system Ni−Ta. I. Oxidation of the intermetallic Ni3Ta. Powder Metall Met Ceram 38, 179–185 (1999). https://doi.org/10.1007/BF02676047

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676047