Abstract

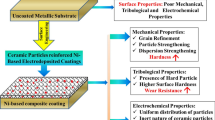

Some experimental works carried out at the Research Institute for Ceramics Technology (IRTEC) and National Physics Laboratory (NPL) on electroconductive ceramics are reviewed. The tests were mainly devoted to characterize mechanical and wear properties of electroconductive particulate composites based on silicon nitride and alumina matrices with reinforcement of nitrides, carbides, and borides. The focus of the study was to ascertain the influence of the sintering techniques and the amount and quality of particle reinforcement on the mechanical and wear performances of the composites with respect to the matrix. The experimental results indicate that,besides the electroconductivity, some mechanical properties can be greatly enhanced by the introduction of a specific amount of intermetallic particles. Unfortunately, the refractoriness of the starting matrix is at the same time reduced, making the composites more sensitive to the temperature effects.

Similar content being viewed by others

References

D. C. Larsen, J. W. Adams, L. R. Johnson, and A. P. S. Teotia,Ceramic Materials for Advanced Eeat Engines, Noyes Publications, Park Ridge (1985).

N. Ichinose,Introduction to Fine Ceramics, John Wiley and Sons Ltd., Chichester (U. K.) (1987).

R. W. Davidge and M. H. Van de Vorde,Design with Structural Ceramics, Elsevier Science Publishers Ltd., Barking (U. K.) (1990).

G. W. Meetham, “High-temperature materials—a general review,”J. Mater. Sci.,26, 853 (1991).

R. Raj, “Fundamental research in structural ceramics for service near 2000°C,”J. Am. Ceram. Soc.,76, 2147–2174 (1993).

S. T. Buljan, J. G. Baldoni, and M. L. Huckabee, “Si3N4−SiC composites,”Am. C Ceram. Soc. Bull.,66, 647–652 (1987).

V. Biasini, S. Guicciardi, and A. Bellosi,Refractory Metals and Hard Materials,11, 213 (1992).

B. Budiansky, J. C. Amazigo, and A. G. Evans, “Small-scale crack bridging and the fracture toughness of particulate-reinforced ceramics,”J. Mech. Phys. Solids.,36, 167–187 (1988).

R. Jimbou, K. Takahashi, Y. Matsushita, and T. Kosugi, “SiC−ZrB2 electroconductive ceramic composites,”Adv. Ceram. Mat.,1, 341–345 (1986).

C. H. McMurtry, W. D. G. Boeker, S. G. Seshadri, et al., “Microstructure and material properties SiC−TiB2 particulate composites,”Am. Ceram. Soc. Bull.,66, 325–329 (1987).

K. Takahashi and R. Jimbou, “Effect of uniformity on the electrical resistivity of SiC−ZrB2 ceramic composites,”J. Am. Ceram. Soc.,70, C369-C373 (1987).

C. Martin, P. Mathieu, and B. Cales, “Electrical discharge machinable ceramic composites,”Mater Sci. Eng.,A109, 351–356 (1989).

N. F. Petrofes and A. M. Gadalla, “Electrical discharge machining of advanced ceramics,”Am. Ceram. Soc. Bull.,67, 1048–1052 (1988).

M. Ramulu, “EDM sinker cutting of a ceramic particulate composite SiC−TiB2,”Adv. Ceram. Mat.,3, 324–327 (1988).

MCIC report (ed.),Engineering Property Data on Selected Ceramics, Vol. 1, Nitrides, Metals and Ceramics Information Center, Battelle, Columbus, Ohio (1976), pp. 5.3.4-1–5.3.4-9.

MCIC report (ed.),Engineering Property Data on Selected Ceramics, Vol. 2, Carbides, Metals and Ceramics Information Center, Battelle, Columbus, Ohio (1987), pp. 5.2.3-1–5.2.3-26.

A. Bellosi, T. Graziani, S. Guicciardi, and A. Tampieri, “Characteristics of TiB2 ceramics,” in:Proc. Special Ceramics 9 (London, 18–20 December 1990), Institute of Ceramics, Shelton (1990).

“Advanced technical ceramics. Mechanical properties at room temperature”,ENV 843-2 Europ. Standard, Part 2, Determination of elastic moduli (1992).

G. R. Anstis, P. Chantikul, B. R. Lawn, and D. B. Marshall, “A critical evaluation of indentation technique for measuring fracture toughness. I. Direct crack measurements,”J. Am. Ceram. Soc.,64, 533–538 (1981).

A. Bellosi, A. Fiegna, and G. N. Babini, “Electroconductive Si3N4-based composites,” in: G. de With, R. A. Terpstra, and R. Metseelar (eds.),Euro-Ceramics, Elsevier Applied Science Publishers, London, Vol. 3 (1989), pp. 389–393.

A. Bellosi, S. Guicciardi, and A. Tampieri, “Development and characterization of electroconductive Si3N4−TiN composites,”J. Europ. Ceram. Soc.,9, 83–93 (1992).

A. Bellosi, G. De Portu, and S. Guicciardi, “Preparation and properties of electroconductive Al2O3-based composites,”J. Europ. Ceram. Soc.,10, 307–315 (1992).

D. J. Magley, R. A. Winholtz, and K. T. Taber, “Residual Stress in a two-phase microcracking ceramic,”J. Am. Ceram. Soc.,73, 1641–1644 (1990).

C.-W. Nan, “Physics of inhomogeneous inorganic materials,”Prog. Mater. Sci.,37, 1–116 (1993).

F. C. Cook and G. M. Pharr, “Mechanical properties of ceramics,” in: R. W. Cahn, P. Haansen, and E. J. Kramer (eds.),Materials Science and Technology. A comprehensive treatment “Structure and properties of ceramics,” Vol. 11, Weinheim, Germany (1994).

I. J. McColm,Ceramic Hardness, Plenum Press, New York (1990).

D. J. Green, “Fracture toughness predictions for crack bowing in brittle particulate composites,”J. Am. Ceram. Soc.,66, C4-C5 (1983).

K. T. Faber and A. G. Evans, “Crack deflection process. I. Theory,”Acta Met.,31, 565–576 (1983).

A. G. Evans and K. T. Faber, “Toughening of circmics by circumferential microcracking,”J. Am. Ceram. Soc. 64, 394–398 (1981).

B. Budiansky, J. C. Amazigo, and A. G. Evans, “Small-scale crack bridging and the fracture toughness of particulate-reinforced ceramics,”J. Mech. Phys. Solids.,36, 167–187 (1988).

M. Taya S. Hayashi, A. S. Kobayashi, and H. S. Yoon, “Toughening of a particulate-reinforced ceramic-matrix composite by thermal residual stress,”J. Am. Ceram. Soc.,73, 1382–1391 (1990).

A. Bellosi, A. Tampieri, and L. Yu-Zhen, “Oxidation behavior of electroconductive Si3N4−TiN composites,”Mater. Sci. Eng.,A127, 115–122 (1990).

C. Melandri, M. Gee, G. De Portu, and S. Guicciardi, “High temperature friction and wear testing of silicon nitride ceramics,”Tribol. Int.,28, 403–413 (1995).

S. Guicciardi and C. Melandri, “Wear of electroconductive Al2O3-based ceramics,” in:Proceedings of International Workshop on Advanced Ceramics (Inuyama (J), 12–14 March, 1966), National Industrial Research Institute of Nagoya (1966), pp. 117–122.

Additional information

Research Institute for Ceramics Technology, National Research Council, Italy. Published in Poroshkovaya Metallurgiya, Nos. 3–4(406), pp. 32–41, March–April, 1999.

Rights and permissions

About this article

Cite this article

Guicciardi, S. Compositional dependence of mechanical and wear properties of electroconductive ceramics. Powder Metall Met Ceram 38, 140–148 (1999). https://doi.org/10.1007/BF02676039

Issue Date:

DOI: https://doi.org/10.1007/BF02676039