Abstract

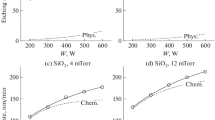

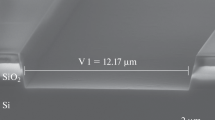

Plasma etching of SiO2} with C2}F6} in a radial flow reactor was investigated to determine relationships between chemical aspects of the discharge, operating parameters such as power and flow rates, and uniformity of etching over a large area. The chemical conversion of C2}F6} in the discharge was monitored by infrared spectrometry of the exhaust gases, as a function of discharge power and gas flow rate. The input gas was found to be transformed mainly to CF2} and a polymeric material, and at sufficiently long residence times (∼1 sec) a "steady state " was achieved. At the steady state condition C2}F6} was found to be ∼60% converted. The amount of conversion was not influenced by the presence of SiO2} being etched, however, the production of CF4} was reduced by the presence of SiO2}. For a known flow rate and reactor dimensions the concentrations of species as a function of radial position in the reactor were calculated. It was demonstrated that the etch rate of SiO2} was dependent on this radial concentration profile. Uniform etching was obtained if the etching zone lay entirely within the "steady state" region of the discharge. Reduced etch rates or polymerization on the substrates was observed if large concentration gradients (rich in C2}F6}existed in the etching zone. It was concluded that the etch rate of SiO2} is dependent then on the local gas composition in the discharge, and can be manipulated by means of adjusting power and gas flow rates.

Similar content being viewed by others

References

C. J. Mogab, W. R. Harshbarger,Electronics 51(18), 117 (1978).

R. A. H. Hieneke,Solid State Electronics 18. 1146 (1975);19, 1039 (1976).

J. A. Bondur,J. Vac, Sci. Technol. 13, 1023 (1976).

G. C. Schwartz, L. B. Zielinski and T. Schopen inEtching, edited by M. J. Rand and H. G. Hughes, Electrochemical Society, New York, p. 122 (1976).

H. W. Lehmann, and R. Widmer,App. Phys. Lett. 32, 163 (1978).

J. W. Coburn, H. F. Winters, and T. J. Chuang,J. App. Phys. 48, 3532 (1977).

J. W. Coburn, E. Kay,Solid State Technol. 22, 117 (1979).

W. R. Harshbarger, R. A. Porter, T. A. Miller and P. Norton,App. Spectroscopy 31, 201 (1977).

C. J. Mogab,J. Electrochem Soc. 124, 1262 (1977).

C. J. Mogab, A. C. Adams and D. L. Flamm,J. App. Phys. 49 3796 (1978).

B. N. Chapman, V. J. Minkiewicz,J. Vac Sci Technol. 15, 329 (1978).

A. R. Reinberg, Abstract No. 6, Electrochem, Soc. Meeting, San Francisco, May 1974; U. S. Patent No. 3,757,733.

E. A. Truesdale and G. Smolinsky, in press,J. App. Phys.

N. L. Craig and D. W. Setser,Int. J. Chem. Kinetics 6, 517 (1974).

G. A. Chamberlain and E. Whittle,J. Chem. Soc. Faraday Trans. 1 68, 88 (1972).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mayer, T.M. Chemical conversion of C2 F6 and uniformity of etching SiO2 in a radial flow plasma reactor. J. Electron. Mater. 9, 513–523 (1980). https://doi.org/10.1007/BF02652933

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652933