Abstract

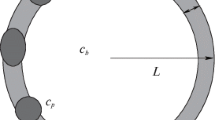

A numerical model has been developed to study the relative effects of nucleation and growth kinetics on the evolution of ultrafine grain structures observed in some supercooled metal powders. The thermal history during solidification is analyzed using a Newtonian heat transfer formulation coupled to classical models for homogeneous nucleation and continuous growth with a diffuse interface. The results indicate that decreasing particle size increases both the supercooling prior to solidification and the thermal excursion beyond the nucleation temperature. After the first nucleus appears, a compctition is established between the formation of new nuclei and the growth of the existing one(s). There is a range of particle sizes in which the achievable supercoolings are high enough to produce massive nucleation before any significant growth—and the ensuing recalescence—can take place. The probability of multiple nucleation may be evaluated from a dimensionless parameter combining the characteristic frequencies of the nucleation, growth, and heat transfer processes at the moment of nucleation. Calculations for Al and Ni model systems confirm the experimental observation that the latter has a stronger tendency to supercool and develop microcrystalline structures.

Similar content being viewed by others

Abbreviations

- a :

-

atomic diameter

- C :

-

molar heat capacity

- d x :

-

grain size

- D :

-

diffusion coefficient

- E v :

-

activation energy for viscous flow

- f :

-

fraction solid

- H :

-

molar enthalpy relative to the solid atT M ,H SM 0

- ΔH M :

-

molar heat of fusion

- h :

-

heat transfer coefficient between the droplet and the environment

- h P :

-

Planck's constant

- I :

-

nucleation rate integrated over time

- J :

-

nucleation frequency, taken as homogeneous

- k B :

-

Boltzmann's constant

- N :

-

number of nuclei or grains in a polycrystalline powder

- N A :

-

Avogadro's number

- R :

-

gas constant

- r 0 :

-

radius of droplet or powder

- T :

-

temperature

- T G :

-

temperature of cooling environment

- T g :

-

glass transition temperature

- T M :

-

melting temperature

- T N :

-

nucleation temperature

- T r :

-

reduced temperature,T/T M

- T :

-

cooling rate

- ΔT :

-

bath supercooling

- ΔT :

-

kinetic supercooling

- ΔT H :

-

characteristic supercooling to hypercool the liquid, ΔM/CL

- ΔT r :

-

reduced supercooling, ΔT/TM

- t :

-

time

- V :

-

interface velocity

- V G :

-

gas/particle relative velocity

- α :

-

thermal diffusivity

- β :

-

kinetic parameter reflecting the ease of interfacial rearrangement

- ε :

-

emissivity

- η :

-

viscosity of the liquid metal

- υ :

-

kinematic viscosity

- γ :

-

solid-liquid interfacial energy

- ρ :

-

Stefan-Boltzmann's constant

- Ω :

-

molar volume

References

P. Joly and R. Mehrabian:J. Mater. Sci., 1974, vol. 9, pp. 1446–55.

S. R. Coriell and R. F. Sekerka: inRapid Solidification Processing, Principles and Technologies II, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor's Publishing Division, Baton Rouge, LA, 1980, pp. 35–49.

W. J. Boettinger, S. R. Coriell, and R. K. Trivedi: inRapid Solidification Processing, Principles and Technologies IV, Proceedings of a Conference at the University of California, Santa Barbara, CA, Dec. 15-18, 1986, in press.

T. Z. Kattamis and R. Mehrabian:J. Vac. Sci. Technol., 1974, vol. 11, pp. 1118–22.

T. Z. Kattamis:J. Crystal Growth, 1976, vol. 34, pp. 215–20.

H. Jones:Rep. Prog. Phys., 1973, vol. 36, p. 1425.

J. J. Valencia, C. G. Levi, and R. Mehrabian: inProcessing of Structural Metals by Rapid Solidification, F. H. Froes and S. J. Savage, eds., ASM INTERNATIONAL, Metals Park, OH, 1987, pp. 1–12.

P. Ramachandrarao, M.G. Scott, and G.A. Chadwick:Phil. Mag., 1972, vol. 25, p. 961.

R. D. Field, E. H. Aigeltinger, and H. L. Fraser: inRapid Solidification Processing, Principles and Technologies II, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor's Publishing Division, Baton Rouge, LA, 1980, pp. 93–99.

C. G. Levi and R. Mehrabian:Metall. Trans. A, 1982, vol. 13A, pp. 13–23.

O. Salas: M.S. Thesis, University of California, Santa Barbara, CA, 1987.

L. A. Bendersky and S. D. Ridder:J. Mater. Res., 1986, vol. 1, pp. 405–14.

J. P. Hirth:Metall. Trans. A, 1978, vol. 9A, pp. 401–04.

P. G. Boswell and G. A. Chadwick:Scripta Metall., 1977, vol. 11, pp. 459–65.

H. Reiss and J. L. Katz: inRapid Solidification Processing, Principles and Technologies, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor's Pub. Div., Baton Rouge, LA, 1978, pp. 64–77.

T.W. Clyne:Metall. Trans. B, 1984, vol. 15B, pp. 369–81.

W. J. Boettinger and J. H. Perepezko: inRapidly Solidified Crystalline Alloys, S.K. Das, B.H. Kear, and C. M. Actam, eds., TMS- AIME, Warrendale, PA, 1985, pp. 21–58.

K. N. Ishihara, M. Maeda, and P.H. Shingu:Acta Metall., 1985, vol. 33, pp. 2113–17.

J. H. Perepezko, B. A. Mueller, and K. Ohsaka: inUndercooled Alloy Phases, E. W. Collings and C. C. Koch, eds., TMS-AIME, Warrendale, PA, 1986, pp. 289–320.

C. G. Levi and R. Mehrabian: inUndercooled Alloy Phases, E. W. Collings and C. C. Koch, eds., TMS-AIME, Warrendale, PA, 1986, pp. 345–74.

M. Cohen, B.H. Kear, and R. Mehrabian: inRapid Solidification Processing, Principles and Technologies II, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor's Publishing Division, Baton Rouge, LA, 1980, pp. 1–23.

G. Horvay: inProc. 4th National Congress of Applied Mechanics, ASME, 1962, p. 1315.

J. L. Walker:Trans. Vacuum Met. Conf., American Vacuum Soc.iety, 1963.

R. Mehrabian: inRapid Solidification Processing, Principles and Technologies, R. Mehrabian, B.H. Kear, and M. Cohen, eds., Claitor's Publishing Division, Baton Rouge, LA, 1978, pp. 9–27.

G. H. Geiger and D. R. Poirier:Transport Phenomena in Metallurgy, Addison Wesley, Reading, MA, 1980.

D. Turnbull and J. C. Fisher:J. Chem. Phys., 1949, vol. 17, p. 71.

J. W. Christian:The Theory of Transformations in Metals and Alloys, 2nd ed., Pergamon Press, Oxford, U.K., 1975, ch. 10.

D. Turnbull:Contemp. Phys., 1969, vol. 10, p. 473.

F. Spaepen:Acta Metall., 1975, vol. 23, pp. 729–43.

D. Turnbull:J. Appl. Phys., 1950, vol. 21, p. 1022.

R. T. Beyer and E. M. Ring: inLiquid Metals: Chemistry and Physics, S. Z. Beer, ed., Marcel Dekker, Inc., New York, NY, 1972, p. 450.

D. Turnbull:Metall. Trans. B, 1981, vol. 12B, pp. 217–29.

J. W. Cahn, W.B. Hillig, and G. W. Sears:Acta Metall., 1964, vol. 12, pp. 1421–39.

N. Eustathopoulos, L. Courdurier, J. C. Joud, and P. Desdre:J. Crystal Growth, 1976, vol. 33, pp. 105–15.

C. G. Levi:Metall. Trans. A, 1988, vol. 19A, pp. 687–97.

J. Perel, J. F. Mahoney, S. Taylor, Z. Shanfield, and C. G. Levi: inRapid Solidification Processing, Principles and Technologies III, R. Mehrabian, ed., National Bureau of Standards, 1982, pp. 458-63.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Levi, C.G. The evolution of microcrystalline structures in supercooled metal powders. Metall Trans A 19, 699–708 (1988). https://doi.org/10.1007/BF02649284

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02649284