Abstract

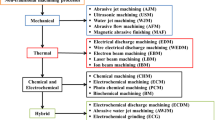

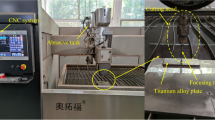

Use of hydro-abrasive jet machining (HAJM) for machining a wide variety of materials—metals, poly-mers, ceramics, fiber-reinforced composites, metal-matrix composites, and bonded or hybridized mate-rials—primarily for two- and three-dimensional cutting and also for drilling, turning, milling, and deburring, has been reported. However, the potential of this innovative process has not been explored fully. This article discusses process control, integration, and optimization of HAJM to establish a plat-form for the implementation of real-time adaptive control constraint (ACC), adaptive control optimiza-tion (ACO), and CAD/CAM integration. It presents the approach followed and the main results obtained during the development, implementation, automation, and integration of a HAJM cell and its computer-ized controller. After a critical analysis of the process variables and models reported in the literature to identify process variables and to define a process model suitable for HAJM real-time control and optimi-zation, to correlate process variables and parameters with machining results, and to avoid expensive and time-consuming experiments for determination of the optimal machining conditions, a process predic-tion and optimization model was identified and implemented. Then, the configuration of the HAJM cell, architecture, and multiprogramming operation of the controller in terms of monitoring, control, process result prediction, and process condition optimization were analyzed. This prediction and optimization model for selection of optimal machining conditions using multi-objective programming was analyzed. Based on the definition of an economy function and a productivity function, with suitable constraints relevant to required machining quality, required kerfing depth, and available resources, the model was applied to test cases based on experimental results.

Similar content being viewed by others

References

L.R.K. Gillespie,Debarring Technology for Improved Manufac- turing, Society of Mechanical Engineers, 1981, p 437–447

M. Hashish, “Milling with Abrasive-Waterjets: A Preliminary In- vestigation,” Proc. 4th U.S. Waterjet Conference, BHRA, 1987. p 1–10

M. Hashish, Turning with Abrasive-Waterjets—A First Investi- gation,Trans. ASME J. Eng. Ind., Vol 111, 1987, p 158–166

M. Hashish, “Turning, Milling, and Drilling with Abrasive-Waterjets,” Proc. 9th Int. Symp. Jet Cutting Technol., BHRA, Sendai, 1988, p 113–131

M. Hashish, An Investigation of Milling with Abrasive-Water Jets,Trans. ASME J. Eng. Ind., Vol 111, 1989, p 158–166

H. Blickwedel, N.S. Guo, H.e.H. Louis Haferkamp, “Prediction of Abrasive Jet Cutting Efficiency and Quality,” Proc. 10th. Int. Symp. Jet Cutting Technology, BHRA, Amsterdam, 1990

K. Faber and H. Oweinah, “Influence of Process Parameters on Blasting Performance with Abrasive-Jet,” Proc. 10th Int Symp. Jet Cutting Technol., Amsterdam, 1990

R. Groppetti and G. Comi, “Contribution to Computer Control and Optimization of Hydro-Abrasive Jet Machining Process,” Proc. 1991 ASME Int. Computers in Engineering, Santa Clara, 1991

M. Hashish, “The Application of Abrasive Jets to Concrete Cut- ting,” Proc. 6th Int. Symp. Jet Cutting Technol., BHRA, Guild- ford, 1982, p 447–464

M. Hashish, “Steel Cutting with Abrasive Waterjets,” Proc. 6th Int. Symp. Jet Cutting Technol., BHRA, Guildford, 1982, p 465–488

R.K. Miller,Water Jet Cutting, Technology and Industrial Appli- cation, The Fairmont Press, Lilburn, 1991, p 3–19/26–42/72–88.

S. Yanagiuchi and H. Yamagata, Cutting and Drilling of Glass by Abrasive Jet, Proc. 8th Int. Symp. Jet Cutting Technol., BHRA, Durham, 1986, p 323–330

M. Hashish, A Model for Abrasive-Waterjet (AWJ) Machining,Trans. ASME J. Eng. Muter. Technol., Vol 111, 1989, p 154–162

W. König and Ch. Wulf, “The Influence of the Cutting Parame- ters on Jet Forces and the Geometry of the Kerf,” Proc. 7th Int. Symp. Jet Cutting Technol., BHRA, Ottawa, 1984, p 179–192

M. Mazurkiewicz and P. Karlic, “Material Dynamic Response during Hydroabrasive Jet Machining (HAJM),” Proc. 4th U.S. Water Jet Conference, ASME, Berkeley, 1987, p 159–167

R. Groppetti, “Implementing CIM in an Experimental Environ- ment Methodology and Case Study,” Proc. 27th Int. Machine Tools Design and Research Conf., UMIST, Manchester, 1988

C. Borasio, R. Groppetti, P. Murchio, and D. Sola, “Experimental Center for System Integration in CIM,” ESPRIT Conference. Brussels, North Holland, 1987

R. Groppetti, “On the Development of a CIM Experimental Cen- ter,” Proc. 17th ISATA, Munich, 1987

R. Groppetti and G. Comi, Studio di una Cella per Processo HAJM (Hydro-Abrasive Jet Machining): Analisi e Sintesi del Sistema di Controllo, Rapporto di Ricerca RG-03-90, Diparti- mento di Meccanica, Politecnico di Milano, 1990

R. Groppetti and G. Comi, Studio ed Implcmentazione di Algo- ritmi di Predizione dello Spessore Tagliato Mediante HJM (Hy- dro-Jet Machining) e HAJM (Hydro-Abrasive Jet Machining). Rapporto di Ricerca RG-04-90, Dipartimento di Meccanica. Politecnico di Milano, 1990

H.-J. Jacobs, B. Hentschel, and B. Stange, Intelligent Tool Moni- toring for Machining,Int. J. Prod. Res.. Vol 26, 1988, p 1579- 1592

R. Groppctti and G. Comi, Analisi Critica di Alcuni Modelli del Processo HAJM (Hydro-Abrasive Jet Machining). Rapporto di Ricerca RG-02-90, Dipartimento di Meccanica, Politecnico di Milano, 1990

M. Hashish, Pressure Effects in Abrasive-Waterjet (AWJ) Ma- chining,Trans. ASME J. Eng. Mater. Technol., Vol 111, 1989, p 221–228

M. Hashish and M.P. Du Plessis, Theoretical and Experimental of Continuous Jet Penetration of Solids.Trans. ASME J. Eng. Ind.. Vol 100, 1978, p 88–94

M. Hashish and M.P. Du Plessis, Prediction Equations: High Ve- locity Jet Cutting Performance to Standoff Distance and Multi- passes,J. Eng. Ind.,Vol 101, 1979, p 311–3 18

S. Kaliszky,Plasticity—Theory and Engineering Applications. Elsevier, Amsterdam, 1989

M. Hashish, A Modeling Study of Metal Cutting with Abrasive Waterjets,Trans. ASME, Vol 106, 1984, p 88–100

M. Hashish, Cutting with Abrasive Waterjets,Mech. Eng., 1984, p 60–69

M. Hashish, “An Improved Model for Erosion by Solid Particle Impact,” Proc. 7th Int. Conf. Erosion by Liquid and Solid Impact. ELSI VII, Cambridge, 1987

D.K.M. Tan, A Model for the Surface Finish in Abrasive-Waterjet Cutting, Proc. 8th Int. Symp. Jet Cutting Technol., BHRA, 1986, p 309–313

S. Yazici and D.A. Summers, “The Use of High Pressure Water- jets in Cutting Foam,” Proc. 4th U.S. Water Jet Symp., BHRA. 1988, p 11–18

M. Hashish, Prediction on Depth of Cut in Abrasive-Waterjet (AWJ) Machining,Trans. ASME J. Eng. Mater. Technol, 1988, p 65–82

H. Arasawa, K. Matsumoto, S. Yamaguchi, and K. Sumita, “Con- trolled Cutting of Concrete Structure with Abrasive Water-Jet,” Proc. 8th Int. Symp. Jet Cutting Technol.. BHRA, 1986, p 211–218

J.L. Cohon, Multiobjective Programming and Planning,Mathe- matics in Science and Engineering, Academic Press, 1978

A.M. Abuelnaga and M.A. Dardiry, Optimization Methods for Metal Cutting,Int. J. Mach. Tool Des. Res., Vol 24, 1984. p 11–18

C.S. Beighter, D.T. Phillips, and D.J. Wilde.Foundations of Op- timization, Prentice-Hall, 1973

B.S. Gottfried and J. Wcisman,Introduction to Optimization The- ory, Prentice-Hall, 1973

R. Groppetti and G. Comi, Studio ed Implementazione di un Al- goritmo di Ottimizzazione Mediante Programmazione Multio- biettvi per il Processo HAJM (Hydro-Abrasive Jet Machining). Rapporto di Ricerca RG-05-90, Dipartimento di Meccanica. Politecnico di Milano, 1990

C. Hwang and A.S. Masud,Multiple Objective Decision Mak- ing—Methods and Applications, Springer-Verlag, 1979, p 164

R.L. Keeney and H. Raiffa,Decisions with Multiple Objectives: Preferences and Value Tradeoffs, John Wiley & Sons, 1976

M. Zeleny,Multiple Criteria Decision Making, Springer-Verlag, 1976, p 123

L. Coes,Abrasives, Applied Mineralogy, Vol 1. Springer-Verlag, 1971. p 24–28/141–153.

T. Isob, H. Yashida, and K. Nishi, “Distribution of Abrasive Par- ticles in Abrasive Water Jet and Accelerations Mechanisms,” Proc. 9th Int. Symp. Jet Cutting Technol., Ottawa. 1984, p 179- 192

M. Simpson, Abrasive Particle Study in High Pressure Water Jet Cutting,Int. J. Water Jet Technol., Vol 1, 1990, p 17–28

P. Yu, A Class of Decisions for Group Decision Problems,Manage. Sci,Vol 19, 1973, p 936

M. Zeleny,Linear Multiobjective Programming, Springer-Verlag, 1974

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Groppetti, R., Jovane, F. Hydro- abrasive jet machining modeling for computer control and optimization. JMEP 2, 421–436 (1993). https://doi.org/10.1007/BF02648831

Issue Date:

DOI: https://doi.org/10.1007/BF02648831