Abstract

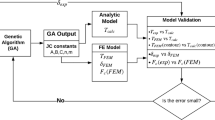

Different process parameters can alter the temperature during machining. Consequently, selecting process parameters that lead to a desirable cutting temperature would help to increase the tool life, decrease the tensile residual stress, and controls the microstructure evolution of the workpiece. An inverse computational methodology is proposed to design the process parameters for a specific cutting temperature. A physics-based analytical model is used to predict the temperature induced by cutting forces. The shear deformation and chip formation model is implemented to calculate machining forces as functions of process parameters, material properties, and etc. To calculate the temperature induced by the deformation in the shear zone, a moving point heat source approach is used. The proposed model uses an iterative non-linear regression to predict the cutting process parameters based on the desirable temperature which is assigned by the user. In order to achieve the cutting process parameters, an iterative gradient search is used to adaptively approach the specific temperature by the optimization of process parameters such that an inverse reasoning can be achieved. Experimental data are used to illustrate the implementation and validate the viability of the computational methodology.

Similar content being viewed by others

References

Yen Y-C, Jain A, Altan T (2004) A finite element analysis of orthogonal machining using different tool edge geometries. J Mater Process Technol 146(1):72–81

Ng E-G, Aspinwall DK, Brazil D, Monaghan J (1999) Modelling of temperature and forces when orthogonally machining hardened steel. Int J Mach Tools Manuf 39(6):885–903

Thiele JD, Melkote SN, Peascoe RA, Watkins TR (2000) Effect of cutting-edge geometry and workpiece hardness on surface residual stresses in finish hard turning of AISI 52100 steel. J Manuf Sci Eng 122(4):642–649

Fernández-Valdivielso A et al (2016) Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc Inst Mech Eng C J Mech Eng Sci 230(20):3725–3742

Ratnasingam J, Ma TP, Ramasamy G (2010) Tool temperature and cutting forces during the machining of particleboard and solid wood. J Appl Sci (Faisalabad) 10(22):2881–2886

Al Hazza MHF et al. Cutting temperature and surface roughness optimization in CNC end milling using multi objective genetic algorithm. in Advanced Computer Science Applications and Technologies (ACSAT), 2012 International Conference on. 2012. IEEE

Umbrello D, Filice L, Rizzuti S, Micari F, Settineri L (2007) On the effectiveness of finite element simulation of orthogonal cutting with particular reference to temperature prediction. J Mater Process Technol 189(1–3):284–291

Özel T, Zeren E (2007) Finite element modeling the influence of edge roundness on the stress and temperature fields induced by high-speed machining. Int J Adv Manuf Technol 35(3–4):255–267

Komanduri R, Hou ZB (2001) Thermal modeling of the metal cutting process—part III: temperature rise distribution due to the combined effects of shear plane heat source and the tool–chip interface frictional heat source. Int J Mech Sci 43(1):89–107

Li K-M, Liang SY (2007) Modeling of cutting forces in near dry machining under tool wear effect. Int J Mach Tools Manuf 47(7–8):1292–1301

Mirkoohi E, Malhotra R (2017) Effect of particle shape on neck growth and shrinkage of nanoparticles. in ASME 2017 12th International Manufacturing Science and Engineering Conference collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing. American Society of Mechanical Engineers.

Shao Y, Li B, Chiang KN, Liang SY (2015) Physics-based analysis of minimum quantity lubrication grinding. Int J Adv Manuf Technol 79:1659–1670

Karpat Y, Özel T (2006) Predictive analytical and thermal modeling of orthogonal cutting process—part I: predictions of tool forces, stresses, and temperature distributions. J Manuf Sci Eng 128(2):435–444

Mirkoohi E, Ning J, Bocchini P, Fergani O, Chiang KN, Liang S (2018) Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers, latent heat, and temperature-sensitivity of material properties. J Manuf Mater Process 2(3):63

AOKI H et al (1997) Use of alternative protein sources as substitutes for fish meal in red sea bream diets. Aquacult Sci 45(1):131–139

Bocciarelli M, Bolzon G, Maier G (2005) Parameter identification in anisotropic elastoplasticity by indentation and imprint mapping. Mech Mater 37(8):855–868

Nakamura EF, Loureiro AA, Frery AC (2007) Information fusion for wireless sensor networks: methods, models, and classifications. ACM Comput Surv (CSUR) 39(3):9–es

Delalleau A, Josse G, Lagarde JM, Zahouani H, Bergheau JM (2006) Characterization of the mechanical properties of skin by inverse analysis combined with the indentation test. J Biomech 39(9):1603–1610

Pujana J, Arrazola PJ, M’Saoubi R, Chandrasekaran H (2007) Analysis of the inverse identification of constitutive equations applied in orthogonal cutting process. Int J Mach Tools Manuf 47(14):2153–2161

Denkena B, Grove T, Dittrich MA, Niederwestberg D, Lahres M (2015) Inverse determination of constitutive equations and cutting force modelling for complex tools using Oxley’s predictive machining theory. Procedia CIRP 31:405–410

Chen X et al (2017) Determining Al6063 constitutive model for cutting simulation by inverse identification method. Int J Adv Manuf Technol:1–8

Laakso SV, Niemi E (2017) Using FEM simulations of cutting for evaluating the performance of different Johnson–Cook parameter sets acquired with inverse methods. Robot Comput Integr Manuf 47:95–101

Mirkoohi E, Bocchini P, Liang SY (2018) An analytical modeling for process parameter planning in the machining of Ti-6Al-4V for force specifications using an inverse analysis. Int J Adv Manuf Technol:1–9

Sivasakthivel P, Sudhakaran R (2013) Optimization of machining parameters on temperature rise in end milling of Al 6063 using response surface methodology and genetic algorithm. Int J Adv Manuf Technol 67(9–12):2313–2323

Yang Wp, Tarng Y (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84(1–3):122–129

Yang Y-K, Shie J-R, Huang C-H (2006) Optimization of dry machining parameters for high-purity graphite in end-milling process. Mater Manuf Process 21(8):832–837

Sridhar B et al (2003) Effect of machining parameters and heat treatment on the residual stress distribution in titanium alloy IMI-834. J Mater Process Technol 139(1–3):628–634

Komanduri R, Hou ZB (2000) Thermal modeling of the metal cutting process: part I—temperature rise distribution due to shear plane heat source. Int J Mech Sci 42(9):1715–1752

Trigger K (1951) An analytical evaluation of metal-cutting temperatures. Trans ASME 73:57

Oxley PLB (1989) The mechanics of machining: an analytical approach to assesing machinability. Ellis Horwood

Johnson GR (1983) A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. Proc. 7th Inf. Sympo. Ballistics, p 541–547

Waldorf DJ, DeVor RE, Kapoor SG (1998) A slip-line field for ploughing during orthogonal cutting. J Manuf Sci Eng 120(4):693–699

Sekhon G, Chenot J (1993) Numerical simulation of continuous chip formation during non-steady orthogonal cutting. Eng Comput 10(1):31–48

Waldorf DJ (2006) A simplified model for ploughing forces in turning. J Manuf Process 8(2):76–82

Duan C et al (2009) Finite element simulation and experiment of chip formation process during high speed machining of AISI 1045 hardened steel. Int J Recent Trends Eng 1(5):46

Özel T, Altan T (2000) Determination of workpiece flow stress and friction at the chip–tool contact for high-speed cutting. Int J Mach Tools Manuf 40(1):133–152

Author information

Authors and Affiliations

Contributions

E.M. conceived and developed the proposed analytical model, extracted and analyzed the data, and wrote the paper. P. B provided general guidance. S.Y.L. provided general guidance and proofread the manuscript writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mirkoohi, E., Bocchini, P. & Liang, S.Y. Analytical temperature predictive modeling and non-linear optimization in machining. Int J Adv Manuf Technol 102, 1557–1566 (2019). https://doi.org/10.1007/s00170-019-03296-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03296-y