Abstract

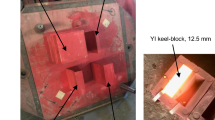

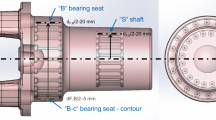

Pig iron ingot molds manufactured with flake, compacted graphite cast iron, and spheroidal graphite cast iron were installed on a pig iron casting machine and subjected to thermal cycling for studying thermal fracture endurance of the three cast irons. The effects of graphite morphology on the fracture mechanism were analyzed by examining the fracture patterns, microstructures, and microcracks in the failed molds. The determining factors of thermal fracture endurance were elucidated with thermal fracture resistance indices. Compacted graphite cast iron exhibited better thermal fracture endurance than flake and spheroidal graphite cast irons because of its higher strength-to-thermal stress ratio.

Similar content being viewed by others

References

S.C. Lee and L.C. Weng:Metall. Trans. A, 1991, vol. 22A, pp. 1821–31.

S.C. Lee and S.C. Chen:Chin. J. Mater. Sci., 1989, vol. 21, pp. 210–23.

K. Roehrig:Am. Foundrymen's Soc. Trans., 1978, vol. 86, pp. 75–88.

K.R. Ziegler and J.F. Wallace:Am. Foundrymen's Soc. Trans., 1984, vol. 92, pp. 735–48.

M. DeCrop, J. Coppolani, and J.C. Margerie:Am. Foundrymen's Soc. Cast Met. Res. J., 1966, vol. 74, pp. 118–39.

E. Nechtelberger:Ver-Bericht A, 1975, No. 22, p. 733.

Y.J. Park, R.B. Gundlack, R.G. Thams, and J.F. Janowak:Am. Foundrymen's Soc. Trans., 1985, vol. 93, pp. 415–22.

H. Fredriksson, P.A. Sunnerkranty, and P. Ljubinkovic:Mater. Sci. Technol., 1988, vol. 4, pp. 222–26.

V.S.R. Murthy and S. Seshan:Am. Foundrymen's Soc. Trans., 1984, vol. 92, pp. 373–80.

W.F. Smith:Structure and Properties of Engineering Alloys, McGraw-Hill Book Co., New York, NY, 1981, pp. 323–24.

R.W. Monroe and C.E. Bates:Am. Foundrymen's Soc. Trans., 1982, vol. 90, pp. 615–24.

G.F.V. Voort:Metallography—Principles and Practices, McGraw-Hill Book Co./Central Book Co., Taipei, Taiwan, 1984, pp. 410–502.

Y. Kondo, K. Yasue, and T. Nishio:Trans. Jpn. Foundrymen's Soc, 1982, vol. 1, pp. 62–65.

M.M. Shea:Am. Foundrymen's Soc. Trans., 1978, vol. 86, pp. 23–30.

R.C. Voigt and S.D. Holmgren:Am. Foundrymen's Soc. Trans., 1990, vol. 98, pp. 213–25.

G. Eichelberg:Engineering, 1939, vol. 148, p. 463.

J.C. Radon, D.J. Burns, and P.P. Benham:J. Iron Steel Inst., 1966, vol. 204, pp. 928–35.

D.P.H. Hasselman:J. Am. Ceram. Soc, 1963, vol. 46, pp. 535–40.

D.O. Morton:Foundry Practice, 1979, No. 200, Fosec Foundries Int. Ltd., Birmingham, United Kingdom, pp. 10–14.

C.F. Walton and T.J. Opar:Iron Casting Handbook, Iron Casting Society, Inc., Cleveland, OH, 1981, p. 278.

I. Minkoff:The Physical Metallurgy of Cast Iron, John Wiley & Sons Inc., New York, NY, 1983, pp. 272–77.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, JL., Lee, SC. Thermal fracture endurance of cast irons with application study of pig iron ingot molds. Metall Mater Trans A 26, 1431–1440 (1995). https://doi.org/10.1007/BF02647593

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647593