Abstract

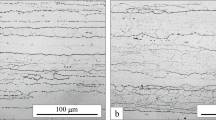

Pound lots of splat cooled 2024 aluminum flake materials were produced by rapidly quenching the atomized melt against a rotating copper disc. Three flake sizes were selected, cold compacted into aluminum cans, and extruded at 300°C at a reduction ratio of 20 to 1. The extruded rods were reduced 50 pct by cold swaging, solution treated at 495°C, water quenched, and naturally aged. The splat cooled 2024 alloy had constituent particles of 1 fim and finer (compared to 5 to 20 μm for the commercial alloy); further, one of the complex constituent phases (AlCuFeMn) was essentially eliminated by the rapid quench. Compared to commercial 2024-T4, the splat cooled 2024 alloys showed 14 to 17 pct increase in yield and tensile strength (no loss of ductility) a seven-fold increase in fatigue life at 30,000 psi, and a large improvement in the 300°F (150°C) stress rupture life in tests beyond 100 h. The fracture characteristics of the splat alloys, while exhibiting excellent to superior ductility, appear inhomogeneous due to the presence of finely dispersed oxide films scattered in the structure.

Similar content being viewed by others

References

P. Duwez, R. H. Willens, and W. Klement, Jr.:J. Appl. Phys., 1960, vol. 31, p. 1136.

N. J. Grant:Fizika 2, Supplement 2, 1970, p. 16.1.

P. Predecki, A. W. Mullendore, and N. J. Grant:Trans. TMS-AIME, 1965, vol. 233, p. 1581.

R. C. Ruhl:Mat. Sci. Eng., 1967, vol. 1, p. 313.

H. Matyja, B. C. Giessen, and N. J. Grant:J. lnst. Met., 1968, vol. 96, p. 30.

P. Duwez:Tram. ASM, 1967, vol. 60, p. 605.

J. A. McComb, S. Nenno, and M. Meshii:J. Phys. Soc. Japan, 1964, vol. 19, p. 1691.

H. Jones:Mat. Sci. Eng., 1969/70, vol. 5, p. 1.

V. K. Sarin and N. J. Grant:Met. Tram., 1972, vol. 3, p. 757.

P. Duwez, R. H. Willens, and R. C. Crewdson:J. Appl. Phys., 1965, vol. 36, p. 2267.

H. S. Chen and D. Turnbull:Appl. Phys. Lett., 1967, vol. 10, p. 284.

R. Ray, B.C. Giessen, and N.J. Grant:Scripta Met., 1968, vol. 2, p. 357.

A. Revcolevschi and N. J. Grant:Met Trans., 1972, vol. 3, p. 1545.

L. N. Moskowitz, R. M. Pelloux, and N. J. Grant:Proc. Second International Conference on Superalloys, September 1972, p. 71, MCIC, Columbus, Ohio.

C. Jansen: Ph.D. Thesis, Department of Metallurgy and Materials Science, Massachusetts Institute of Technology, 1971.

M. Itagaki, B. C. Giessen, and N. J. Grant:Trans. ASM, 1968, vol. 61, p. 330.

M. Moss and D. M. Schuster:Trans. ASM, 1969, vol. 62, p. 201.

C. P. Hinesley and J. G. Morris:Met. Trans., 1970, vol. 1, p. 1476.

T. Toda and R. Maddin:Tram. TMS-AIME, 1969, vol. 245, p. 1045.

J. E. Hilliard:Metal Progress, 1964, vol. 85, p. 99.

J. E. Hilliard and J. W. Cahn:Tram. TMS-AIME, 1961, vol. 221, p. 344.

E. H. Dix, Jr.: Preprint No. 574, Institute of Aeronautical Sciences, New York, 1955.

Alcoa Research Center, private communication.

F. Keller and G. W. Wilcox:Metal Progress, 1933, vol. 23, p. 38.

G. Phragmen:J. lnst. Metals, 1950, vol. 77, p. 489.

P. R. Sperry:Met. Trans., 1970, vol. 1, p. 1465.

H. W. Antes and H. Markus:Met. Eng. Quart., 1970, vol. 10, p. 9.

J. P. Lyle, Jr.:Aluminum, “Properties, Physical Metallurgy and Phase Diagrams”, K. R. Van Horn, ed., American Society for Metals, Metals Park, Ohio, 1967.

C. E. Mobley, A. H. Clauer, and B. A. Wilcox:J. lnst. Met., 1972, vol. 100, p. 142.

K. Erhardt and N. J. Grant:Fracture, Proc. of the Second International Con- ference on Fracture, Brighton, England, 1969, Chapman and Hall, Ltd., London.

J. C. Grosskreutz: Ibid..

J. C. Grosskreutz, G. C. Shaw, and D. K. Benson: AFML, Wright-Patterson Air Force Base, TR-69-121, 1969.

A. S. Bufferd and N. J. Grant:Trans. ASM, 1967, vol. 60, p. 305.

Aluminum: Properties, Physical Metallurgy and Phase Diagrams, 1967, vol. 1, p. 22, ASM, Metals Park, Ohio.

Author information

Authors and Affiliations

Additional information

Formerly Research Assistant, Department of Metallurgy and Materials Science, Massachusetts Institute of Technology

Rights and permissions

About this article

Cite this article

Lebo, M., Grant, N.J. Structure and properties of a splat cooled 2024 aluminum alloy. Metall Trans 5, 1547–1555 (1974). https://doi.org/10.1007/BF02646325

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02646325