Abstract

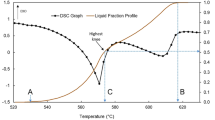

This study aims to evaluate the microstructure and mechanical behavior of Al–Si–Cu alloys (Al–wt%Si–2.5wt%Cu, Al–5wt%Si–2.5wt%Cu, and Al–7wt%Si–2.5wt%Cu) thixoforged through controlled partial melting. The alloys were subjected to temperatures that ensured a solid fraction of 45% and held for varying durations of 0, 30, 90, and 210 s. They were then immediately thixoforged in two different types of equipment: eccentric and a pneumatic press. The thermal treatments promote globularization of the primary-phase particles, with globules measuring around 70 µm. Tensile testing was carried out to characterize the mechanical behavior, and the results were equivalent or superior to those obtained for the as-cast structures. The thixoforged alloys were also subjected to T4 heat treatment with a solution treatment temperature of 540 °C for 10 h. Better distribution of the Si eutectic and a reduction in the size of the Si particles compared with the as-cast conditions were achieved. T4 treatment resulted in a significant improvement in mechanical properties, especially for the Al7Si2.5Cu alloy thixoforged in a pneumatic press, for which the yield strength reached 200 MPa, the ultimate tensile strength 292 MPa and the elongation 7.6%. Results indicate the feasibility of using these alloys to produce metal parts by thixoforging, especially when a pneumatic press is used.

Similar content being viewed by others

References

M.C. Flemings, Metall. Trans. A 22, 957–981 (1991). https://doi.org/10.1007/BF02661090

H.V. Atkinson, Prog. Mater. Sci. 50, 341–412 (2005). https://doi.org/10.1016/j.pmatsci.2004.04.003

M.S. Salleh, M.Z. Omar, J. Syarif, M.N. Mohammed, ISRN Mater. Sci. (2013). https://doi.org/10.1155/2013/679820

S. Nafisi, R. Ghomashchi, Semisolid Processing of Aluminum Alloys: Semisolid metal (SSM) Technologies (Springer, Cham, 2016), pp.9–48. https://doi.org/10.1007/978-3-319-40335-9

M.P. Kenney, R.D. Courtois, G.M. Evans, C.P. Farrior, A.A. Koch, K.P. Young, Semi solid metal casting and forging, in Metals Handbook, 9th ed., ASM International, Materials Park, Ohio, USA, vol.15, 327-338 (1998).

E.J. Zoqui, Alloys for semisolid processing, in Comprehensive Materials Processing. ed. by S. Hashmi, G.F. Batalha, C.J. Van Tyne, B. Yilbas (Elsevier, 2014), pp.163–190

Y. Birol, J. Mater. Proc. Tech. 186(1–3), 94–101 (2007). https://doi.org/10.1016/j.jmatprotec.2006.12.021

E. Velasco, S. Valtierra, J.F. Mojica, J. Talamantes, S. Cano, R. Colas, Metall. Mater. Trans. B 30, 773–778 (1999). https://doi.org/10.1007/s11663-999-0039-0

G.M. Poole, M. Heyen, L. Nastac, N. El-Kaddah, Metall. Mater. Trans. B 45, 1834–1841 (2014). https://doi.org/10.1007/s11663-014-0090-3

L.V. Torres, E.J. Zoqui, Metall. Mater. Trans. B 53, 3229–3245 (2022). https://doi.org/10.1007/s11663-022-02602-6

M.S. Salleh, M.Z. Omar, J. Syarif, K.S. Alhawari, M.N. Mohammed, J. Mater. Des. 64, 142–152 (2014). https://doi.org/10.1016/j.matdes.2014.07.014

R. Ghiaasiaan, S. Shankar, Int. J. Metalcast. 13, 300–310 (2019). https://doi.org/10.1007/s40962-018-0254-z

E.J. Zoqui, L.A. Lourençato, D.M. Benati, Sol. State Phen. 141–143, 517–522 (2008). https://doi.org/10.4028/www.scientific.net/ssp.141-143.517

R.L. Nadal, A.S. Roca, H.D.C. Fals, E.J. Zoqui, J. Mater. Proc. Tech. 226, 146–156 (2015). https://doi.org/10.1016/j.jmatprotec.2015.07.015

ASTM – American Society for Testing and Materials. B557M-02a: Standard test methods of tension testing wrought and cast aluminum and magnesium-alloy products, 15p, (2002). https://doi.org/10.1520/B0557-02A.

ASTM – American Society for Testing and Materials. E112: Standard test methods for determining average grain size, 26p, (1996). https://doi.org/10.1520/E0112-13.

T. Haskel, G.O. Verran, R. Barbieri, Int. J. Fatigue 114, 1–10 (2018). https://doi.org/10.1016/j.ijfatigue.2018.04.012

O. Bustos, S. Ordoñez, R. Colás, Inter. J. Metalcast. 7, 29–37 (2013). https://doi.org/10.1007/BF03355542

C.T.W. Proni, E.J. Zoqui, Inter. J. Mater. Res. 108, 228–236 (2017). https://doi.org/10.3139/146.111472

S.Y. Chang, A. Fukatsu, H. Tezuka, A. Kamio, Mater. Trans. JIM 40(6), 546–551 (1999). https://doi.org/10.2320/matertrans1989.40.546

X. Yang, X. Shuisheng, M. Tller, T. Altan, An investigation to determination the influence of geometric parameters on semisolid metal flow, in Proceeding of the 6th International Conference on Semisolid Processing of Alloy and Composites. Turin, 2000, p.789-793.

E.J. Zoqui, M. Paes, E. Es-Sadiqi, J. Mater. Proc. Tech 120(1–3), 365–373 (2002). https://doi.org/10.1016/S0924-0136(01)01148-7

A. Guo, X. Qiu, Z. Ke, J. Zhao. Inter. J. Metalcast. 16, 663–673 (2022). https://doi.org/10.1007/s40962-021-00621-8

M. Tiryakioğlu, R.T. Shuey, Metall. Mater. Trans. B 38, 575–582 (2007). https://doi.org/10.1007/s11663-007-9027-4

S.K. Chaudhury, D. Apelian, Metall. Mater Trans. A 37(3), 762–778 (2006). https://doi.org/10.1007/s11661-006-0048-4

W. Jiang, Z. Fan, D. Liu, D. Liao, X. Dong, X. Zong, Mater. Sci. Eng. A 560, 396–403 (2013). https://doi.org/10.1016/j.msea.2012.09.084

C.H. Cáceres, C.J. Davidson, J.R. Griffiths, Mater. Sci. Eng. A 197(2), 171–179 (1995). https://doi.org/10.1016/0921-5093(94)09775-5

Z. Lang, F. Wang, W. Wang, Z. Wang, L. Zhou, P. Mao, Z. Liu, Inter. J. Metalcast. 17, 481–498 (2023). https://doi.org/10.1007/s40962-022-00788-8

M. Qi, B. Li, P. Zhang, Y. Kang, G. Zhang, J. Wang, Q. Deng, W. Jiang, B. Hao, J. Li. Mater. Sci. Eng. A 861, 144312 (2022). https://doi.org/10.1016/j.msea.2022.144312

M.A. Abdelgnei, M.Z. Omar, M.J. Ghazali, M.N. Mohammed, Inter. J. Metalcast. 16, 370–384 (2022). https://doi.org/10.1007/s40962-021-00610-x

Acknowledgements

The authors would like to thank FAPESP (the State of São Paulo Research Foundation - Fapesp projects no. 2009/08478-1 and 2022/05050-5) and CNPq (the National Council for Scientific and Technological Development - project no. Pq 303299-2021-5). The authors also extend their thanks to the Faculty of Mechanical Engineering at the State University of Campinas, UNICAMP, and the Federal Institute of Education, Science and Technology of São Paulo, IFSP, Bragança Paulista campus.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Torres, L.V., Zoqui, E.J. Mechanical Properties of Thixoformed Al–Si–Cu Alloys. Inter Metalcast 18, 769–788 (2024). https://doi.org/10.1007/s40962-023-01086-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01086-7