Abstract

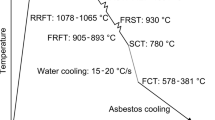

The influence of microstructural variations on the fracture toughness of two tool steels with compositions 6 pct W-5 pct Mo-4 pct Cr-2 pct V-0.8 pct C (AISI M2 high-speed steel) and 2 pct W-2.75 pct Mo-4.5 pct Cr-1 pct V-0.5 pct C (VASCO-MA) was investigated. In the as-hardened condition, the M2 steel has a higher fracture toughness than the MA steel, although the latter steel is softer. In the tempered condition, MA is softer and has a higher fracture toughness than M2. When the hardening temperature is below 1095 °C (2000 °F), tempering of both steels causes embrittlement,i.e., a reduction of fracture toughness as well as hardness. The fracture toughness of both steels was enhanced by increasing the grain size. The steel samples with intercept grain size of 5 (average grain diameter of 30 microns) or coarser exhibit 2 to 3 MPa√m (2 to 3 ksi√in.) higher fracture toughness than samples with intercept grain size of 10 (average grain diameter of 15 microns) or finer. Tempering temperature has no effect on the fracture toughness of M2 and MA steels as long as the final tempered hardness of the steels is constant. Retained austenite has no influence on the fracture toughness of as-hardened MA steel, but a high content of retained austenite appears to raise the fracture toughness of as-hardened M2 steel. There is a temperature of austenitization for each tool steel at which the retained austenite content in the as-quenched samples is a maximum. The above described results were explained through changes in the microstructure and the fracture modes.

Similar content being viewed by others

References

K. Kiyonaga:Toward Improved Ductility and Toughness, Climax Molybdenum Company (Japan) Ltd., 1971, p. 207.

K. Erickson:Scand. J. Met., 1973, vol. 2, p. 197.

U. Häfte, H. Blumenauer, and G. Pusch:Neue Hütte, 1974, vol. 19, no. 1, p. 54.

G. Berry: “Toughness of Tool Materials,” Final S. R. C. Report, Dept. of Mech. Eng., Univ. of Sheffield, 1974.

G. Berry and M. J. Kadhim Al-Tomachi:Proc. 15th International Machine Tool Design and Research Conf., S. Tobias and F. Koenigsberger, eds., MacMillan Press Ltd., 1975, p. 713.

A. R. Johnson:Metall. Trans. A, 1977, vol. 8A, p. 891.

G. Berry and M. J. Kadhim Al-Tomachi:Metals Technology, 1977, vol. 4, p. 289.

H. Johansson:Metall. Trans. A, 1978, vol. 9A, p. 95.

L. M. Barker and W. C. Leslie:Fracture 1977, Waterloo, Canada, 1977, vol. 2, p. 305.

L. R. Olsson and H. F. Fischmeister:Powder Met., 1978, no. l, p. 13.

J. A. Rescalvo and B. L. Averbach:Metall Trans. A, 1979, vol. 10A, p. 1265.

S. C. Lee and F. J. Worzala:Metall. Trans. A, 1981, vol. 12A, p. 1477.

E. Horn and H. Brandis:DEW-Techn. Ber., 1971, vol. 11, no. 3, p. 147.

E. Kula and M. Cohen:Trans. ASM, 1954, vol. 46, p. 727.

A. H. Grobe, G. A. Roberts, and D. S. Chambers:Trans. ASM, 1954, vol. 46, p. 759.

C. Kim, V. Biss, and W. F. Hosford:Metall. Trans. A, 1982, vol. 13A, p. 185.

J. Durnin and K. A. Ridai:J1SI, 1968, vol. 206, p. 60.

C. J. M Mahon, Jr.:Temper Embrittlement, ASTM STP 407, 1968, p. 127.

G. Thomas:Metall. Trans. A, 1978, vol. 9A, p. 439.

H. K. D. H. Bhadeshia and D. V. Edmonds:Metal Sci., 1979, vol. 13, p. 325.

J. N. Robinson and C. W. Tuck:Eng. Fract. Mech., 1972, vol. 4, p. 377.

D. A. Curry and J. F. Knott:Metal Sci., 1976, vol. 10, p. 1.

G. Y. Lai, W. E. Wood, R. A. Clark, V. F. Zackay, and E. R. Parker:Metall. Trans., 1974, vol. 5, p. 1663.

R. O. Ritchie, B. Francis, and W. L. Server:Metall. Trans. A, 1976, vol. 7A, p. 831.

R. O. Ritchie and R. M. Horn:Metall. Trans. A, 1978, vol. 9A, p. 331.

D. S. McDarmaid:Metals Technology, 1978, vol. 5, p. 7.

W. E. Wood:Eng. Franct. Mech., 1975, vol. 7, p. 219.

R. A. Grange:Trans. ASM, 1966, vol. 59, p. 26.

P. Gordon, M. Cohen, and R. S. Rose:Trans. ASM, 1944, vol. 33, p. 411.

M. Cohen:Trans. ASM, 1949, vol. 41, p. 35.

W. C. Leslie and R. L. Miller:Trans. ASM, 1964, vol. 57, p. 972.

S. D. Antolovich, A. Saxena, and G. R. Chanani:Metall. Trans., 1974, vol. 5, p. 623.

W. W. Gerberich, P. L. Hemmings, V. F. Zachay, and E. R. Parker:Fracture 1969, Proc. of 2nd Int. Conf. on Fracture, Brighton, U. K., Chapman and Hall Ltd., 1969, p. 288.

Author information

Authors and Affiliations

Additional information

CHONGMIN KIM, formerly with Climax Molybdenum Company of Michigan, Ann Arbor, MI.

Rights and permissions

About this article

Cite this article

Kim, C., Johnson, A.R. & Hosford, W.F. Fracture toughness of aisi M2 high-speed steel and corresponding matrix tool steel. Metall Trans A 13, 1595–1605 (1982). https://doi.org/10.1007/BF02644800

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02644800