Abstract

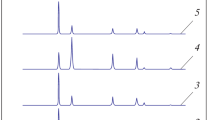

Interrupted hot torsion tests at 450 °C have been performed on homogenized as-cast specimens of Al-Mg alloys. The chemical compositions are approximately Al-4.85 pct Mg-0.74 pct Mn-0.22 pct Cr. The testpieces have been homogenized by three different heating schedules, and the number of revolutions to fracture in hot torsion tests has been measured. The tests lead to the finding that minor Si impurity, as little as 0.05 pct, is very harmful to the hot ductility. On the other hand, Fe impurity up to 0.34 pct has no influence. It is also found that homogenization schedule is very important to hot ductility. A two-stage heating consisting of a preheating at 430 °C for one and a half hours plus a soaking at 530 °C for eight hours results in the best hot ductility. Three different kinds of interdendritic precipitates of the compositions (Fe, Mn)Alx, (Cr, Mn, Fe, Ti)Al7, and Mg2Si have been identified by electron microscopy. After homogenization submicron dispersoids of the composition MnAl6, containing Fe and Cr as alloying elements, precipitate within the dendrites. These dispersoids are shown to exert major influences on hot ductility.

Similar content being viewed by others

References

M. Mizuno and H. Nagaoka:Int. Met. Rev., 1979, no. 2, pp. 68–81.

S.-T. Wu and D.-C. Wang: National Tsing Hua Univ., Hsinchu, Taiwan, R. O. C, unpublished work.

S.J. Paterson and T. Sheppard:Met. Technol., 1982, vol. 9, pp. 389–98.

J. R. Cotner and W. J. McG. Tegart:J. Inst. Metals, 1969, vol. 97, pp. 73–79.

M. A. Zaidi and T. Sheppard:Met. Technol., 1984, vol. 11, pp. 313–19.

H. Shiro, N. Tadahisa, and U. Masanori:J. Jpn. Inst. Light Met., 1978, vol. 28, pp. 3–7.

K. Yoshikawa, T. Sakamoto, T. Mon, and H. Takada:J. Jpn. Inst. Light Met., 1979, vol. 29, no. 4, pp. 144–52.

A.L. Dons:Scand. J. Metallurgy, 1984, vol. 13, pp. 137–43.

H. Shiro, N. Iadahisa, and U. Masanori:J. Jpn. Inst. Light Met., 1977, vol. 27, pp. 579–83.

J. E. Hatch: “Aluminum, Properties and Physical Metallurgy,” ASM, 1984, p. 99.

J. E. Hatch: “Aluminum, Properties and Physical Metallurgy,” ASM, 1984, p. 221.

Author information

Authors and Affiliations

Additional information

Formerly Head of Materials Research with Materials Research Laboratories, Industrial Technology Research Institute.

Rights and permissions

About this article

Cite this article

Lee, SL., Wu, ST. Influence of soaking treatments on hot ductility of Al-4.85 pct Mg alloys containing Mn. Metall Trans A 17, 833–841 (1986). https://doi.org/10.1007/BF02643859

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643859