Abstract

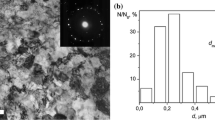

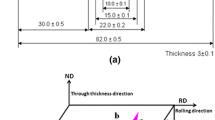

The mechanical properties of Ti-7 Mo-7 Al and Ti-7 Mo-16 Al (in at. pct) were correlated to the microstructure. The mechanical properties of the alloy with low aluminum content, consisting of α+ β phases, were dependent on the size of the α particles. Although the α phase is softer than the β phase, the small α particles, upon plastic deformation of the alloy, functioned as typical hard agents in a dispersion-hardened system and the volume fraction of the particles controlled the macroscopic ductility. A rapid strain-hardening behavior of the small α particles seemed to be responsible for this effect. Large α particles behaved like soft, incoherent particles, the volume fraction having little effect on the inherent ductility of the alloy. The two phase (β+ Ti3Al) microstructure of the alloy with high aluminum content resulting from high temperature aging to 900°C exhibited a yield stress of 130 ksi and an elongation to fracture of 5 pct. The ductility of this microstructure was controlled by the volume fraction of the Ti3Al particles inducing homogeneous slip. The favorable ductility properties of the microstructures with low Ti3Al volume fraction were lost if the slip mode was changed from homogeneous slip to planar slip.

Similar content being viewed by others

References

C. A. Luke, R. Taggarl, and D. H. Polonis:Trans. ASM, 1958, vol. 50, p. 455.

Yu. A. Bagaryatskii and G. I. Nosova:Fiz. Metall. Metalloved., 1962, vol. 13, p. 415.

J.C. Williams, B. S. Hickman, and H. L. Marcus:Met. Tram., 1971, vol. 2, p. 1913.

H. Margolin, P. A. Farrar, and M. A. Greenfield:The Science, Technology and Application of Titanium, R. I. Jaffee and N. E. Promisel, eds., pp. 795–808, Pergamon Press, 1970.

T. Jamajima, G. Lütjering, and S. Weissmann:Met. Trans., 1972, vol. 3, pp. 2805–10.

M. J. Blackburn and J. C. Williams:Trans. TMS-AIME, 1967, vol. 239, p. 287.

P. B. Hirsch:Prog. Met. Phys., 1956, vol. 6, p. 282.

G. Lütjering: DFVLR, Porz-Wahn, Germany, 1972, private communication.

H. Böhm and B. Löhberg:Z. Metallk., 1958, vol. 49, p. 173.

G. Lütjering and S. Weissmann:Acta Met., 1970, vol. 18, p. 785.

Author information

Authors and Affiliations

Additional information

Formerly Staff Member, Materials Research Center, Allied Chemical Corp., Morristown, N. J.

Rights and permissions

About this article

Cite this article

Hamajima, T., Lütjering, G. & Weissmann, S. Importance of slip mode for dispersion-hardened β-titanium alloys. Metall Trans 4, 847–856 (1973). https://doi.org/10.1007/BF02643096

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02643096