Abstract

The tool-balancing system described in this paper regulates the selected tools for the machining of a certain component on a turning centre and optimises the tool-changing strategy on a machining-cost basis.

The regulation of the tools represents a correlation between the total number of tools selected and the available tool positions on the machine tool. When there are free tool positions on the turret, duplicates of the high-wear tools can be used in order to reduce the number of interruptions for tool changing. When the number of tools is greater than the number of turret positions, some tools are automatically replaced by others which are already being used for different operations and which offer geometrical suitability and compatible performance.

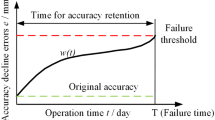

Further, the tool-changing strategy is optimised by modifying the optimum tool life and/or the cutting data. The system has been successfully tested for a variety of applications and it has resulted in increased productivity and machinetool utilisation.

Similar content being viewed by others

References

P. Maropoulos, “Automatic tool selection and balancing for CNC turning centres”, PhD thesis, UMIST, 1988.

E. Doyle, “Optimum cutting speed and tool replacement policy with variable tool life”,SME Manufacturing Engineering Transactions, p. 1, 1973.

S. Ramalingam, N. Balasubramanian and Y. Peng, “Tool life scatter, tooling cost and replacement schedules”,Manufacturing Engineering Transactions, Proceedings of the Fifth NAMR Conference, p.212, 1977.

A. K. Sheikh, L. A. Kendall and S. M. Pandit, “Probabilistic optimization of multi-tool machining operations”,ASME Journal of Engineering for Industry, 102, p. 239, 1980.

U. La Commare, S. Noto La Diega and A. Passanati, “Tool replacement strategies by computer simulation”,Proceedings of the Fourth International Conference on Production Control in the Metalworking Industry, 1986.

U. La Commare, S. Noto La Diega and A. Passanati, “Optimum tool replacement policies with penalty costs for unforseen tool failures”,Journal of Machine Tool Design and Research, 23, p. 237, 1983.

W. K. Aachen, “In-process monitoring of cutting tool forces”,Second Biennial International Machine Tool Technology Conference, 11, pp. 83–99, 1984.

K. Taraman, R. Swando and W. Yamauchi, Relationship between tool forces and flank wear”,SME Technical Paper no. MR74, p. 704, 1974.

G. Schaffer, “Sensors: the eyes and ears of CIM”,American Machinist, 127(7), pp. 109–24, 1983.

J. Tlusty and G. C. Andrews, “A critical review of sensors for unmanned machining”,Annals of the CIRP, 127(2), pp. 563–72, 1983.

A. Novak, “Monitoring of the tool conditions by means of the photodiode arrays”,Manufacturing Systems, 12(3), pp. 245–55, 1983.

G. F. Michelleti, W. Koenig and H. R. Victor, “In-process tool wear sensors for cutting operations”,Annals of the CIRP, 25(2), pp. 483–96, 1976.

L. V. Colwell, J. C. Mazur and J. Angell, “Progress report, diagnostic sensing in maching operations”, project 320357, University of Michigan, 1975.

S. Hinduja and G. Barrow, “TECHTURN: a technologically oriented system for NC lathes”,First CAPEConference, Edinburgh, April 1986.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Maropoulos, P., Hinduja, S. A tool-regulation and balancing system for turning centres. Int J Adv Manuf Technol 4, 207–226 (1989). https://doi.org/10.1007/BF02601521

Issue Date:

DOI: https://doi.org/10.1007/BF02601521