Abstract

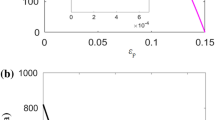

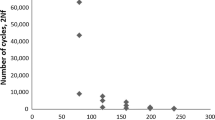

Particle fracture during the extrusion of a 6061/Al2O3/20p composite has been modeled using a modified comminution formulation. It has been assumed that the particles contain a Poisson distribution of flaws, and that the distribution is specific to the alumina and the method of production; the particle distribution in the extrudate was characterized by the Rosin-Rammler (RR) distribution. The model relates macroscopic deformation variables to fracture and, starting with the distribution in the as-cast material in each case, is able to predict with reasonable accuracy changes in size distribution for three extrusion ratios. Some discrepancy between prediction and experiment occurs at small sizes. This is believed to result mainly from inaccuracies in the measured data and effects of the continuous size distribution in representing a set of discontinuous data. The model is potentially generalizable to any particulate-reinforced metal matrix composite (MMC).

Similar content being viewed by others

References

K.-T. Park, E.J. Lavernia, and F.A. Mohamed:Acta Metall. Mater., 1990, vol. 38, pp. 2149–59.

W. Dixon:5th Int. Aluminum Extrusion Technology Seminar, The Aluminum Association, Washington, 1992, vol. 1, pp. 429–36.

D.J. Lloyd:Acta Metall. Mater., 1991, vol. 39, pp. 59–71.

W.H. Hunt, Jr., J.R. Brockenbrough, and P.E. Magnusen:Scripta Metall. Mater., 1991, vol. 25, pp. 15–20.

J.D. Embury, J. Newell, and S. Tao:Metal Matrix Composites—Processing, Microstructure and Properties, Proc. 12th Risø Int. Symp. on Materials Science, N. Hansen, D. Juul Jensen, T. Leffers, H. Lilholt, T. Lorentzen, A.S. Pedersen, O.B. Pedersen, and B. Ralph, eds., Risø National Laboratory, Roskilde, Denmark, 1991, pp. 317–22.

W.S. Miller and F.J. Humphreys:Scripta Metall. Mater., 1991, vol. 25, pp. 33–38.

J.D. Embury: inModeling the Deformation of Crystalline Solids, T.C. Lowe, A.D. Rollet, P.S. Follansbee, and G.S. Daehn, eds., TMS, Warrendale, PA, 1991, pp. 439–56.

P.M. Mummery, B. Derby, and C.B. Scruby:Acta Metall. Mater., 1993, vol. 41, pp. 1431–45.

D.S. Liu, M. Manoharan, and J.J. Lewandowski:Metall. Trans. A, 1989, vol. 20A, pp. 2409–17.

Y. Brechet, J.D. Embury, S. Tao, and L. Luo:Acta Metall. Mater., 1991, vol. 39, pp. 1781–86.

J. Llorca:Acta Metall. Mater., 1995, vol. 43, pp. 181–92.

T.R. McNelley and P.N. Kalu:Scripta Metall. Mater., 1991, vol. 25, pp. 1041–46.

W.-C. Chen: Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1995.

W.-C. Chen, C.H.J. Davies, I.V. Samarasekera, E.B. Hawbolt, and J.K. Brimacombe:Metall. Mater. Trans. A, 1996, vol. 27A, pp. 0000–00 accepted for publication.

T. Mochida, M. Taya, and D.J. Lloyd:Mater. Trans. JIM, 1991, vol. 32, pp. 931–42.

B.J.M. Aikin and T.H. Courtney:Metall. Trans. A, 1993, vol. 24A, pp. 2467–71.

J. Llorca and P. Poza:Mater. Sci. Eng., 1994, vol. A185, pp. 25–37.

C.H.J. Davies, W.-C. Chen, E.B. Hawbolt, I.V. Samarasekera, and J.K. Brimacombe:Scripta Metall. Mater., 1995, vol. 32, pp. 309–15.

T. Allen:Particle Size Measurement, 4th. ed., Chapman & Hall, London, 1990, p. 161.

K. Wallin, T. Saario, and K. Törrönen:Int. J. Fract., 1987, vol. 32, pp. 201–09.

B.R. Lawn:Fracture of Brittle Solids, 4th ed., CUP, Cambridge, UK. 1993, p. 12ff.

G.J. Richardson, D.N. Hawkins, and C.M. Sellars:Worked Examples in Metalworking, Institute of Materials, London, 1985, p. 141.

C.H.J. Davies, W.-C. Chen, I.V. Samarasekera, E.B. Hawbolt, and J.K. Brimacombe: inHigh Performance Metal and Ceramic Matrix Composites, K. Upadhya, ed., TMS, Warrendale, PA, 1994, pp. 195–202.

F.J. Humphreys and P.N. Kalu:Acta Metall., 1987, vol. 35, pp. 2815–29.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Davies, C.H.J., Chen, W.C., Lloyd, D.J. et al. Modeling particle fracture during the extrusion of aluminum/alumina composites. Metall Mater Trans A 27, 4113–4120 (1996). https://doi.org/10.1007/BF02595659

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02595659