Abstract

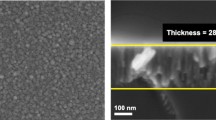

Various laser treatments have been developed for metallic surface modification. In these processes, rapid heating of a specific area on the surface by a laser is the critical feature employed to produce a different phase or layer on the surface. The laser beam mode, such as a Gaussian, rectangular, or annular beam in a stationary or spinning state, has been found to have a very important effect in the laser processing. Many significant models have been established to estimate the temperature field developed by a laser and therefore to predict the optimum conditions in the process, but these models are mainly applicable to a stationary beam. Previous work has shown the advantages in some applications of using a spinning beam. Therefore, modeling work for a spinning beam is necessary. The present article reworked our previous model on a spinning beam mode for a continuous CO2 laser, to calculate a two-dimensional temperature profile by using a line source and superposition of a number of Gaussian sources. An excellent agreement with experimental work for a nitrided Ti-6Al-4V alloy (IMI 318) for a situation of a small (50-µm) melt pool was achieved. A relationship was derived between the normalized laser power and specimen speed to produce a uniformly thick surface layer.

Similar content being viewed by others

References

A. Schüssler, P.H. Steen, and P. Ehrhard:J. Appl. Phys., 1992, vol. 71, pp. 1972–75.

K. Uenishi, A. Sugimoto, and K.F. Kobayashi:Z. Metallkd., 1992, vol. 83, pp. 241–45.

N.B. Dahotra, T.D. McCay, and M.H. McCay:J. Appl. Phys. 1989, vol. 65, pp. 5072–77.

C.W. Draper and J.M. Poate:Int. Met. Rev., 1985, vol. 30, pp. 85–108.

K.P. Cooper and J.D. Ayers:Surf. Eng., 1985, vol. 1, pp. 263–72.

G. Abbas and D.R.F. West:Wear, 1991, vol. 143, pp. 353–63.

K. Mohammed Jasim, R.D. Rawlings, R. Sweeney, and D.R.F. West:Mater. Sci. Lett., 1992, vol. 11, pp. 414–17.

S. Mridha, C. Hu, H.S. Ubhi, A.W. Bowen, and T.N. Baker:Proc. World Conf. on Titanium, Birmingham, United Kingdom, Oct. 1995, in press.

C. Hu and T.N. Baker: Final Report on Laser Processing of Titanium Alloy, MOD Research Agreement No. D/ERI/9/4.2065/073/XR/STR, June 1995.

H.E. Cline and T.R. Anthony:J. Appl. Phys., 1977, vol. 48, pp. 3895–3900.

N.N. Rykalin, A.A. Ugloy, and M.M. Nizametdinov:Sov. J. Quantum Electron, 1977, vol. 7, pp. 853–56.

M. Lax:J. Appl. Phys., 1977, vol. 48, pp. 3919–24.

Y.I. Nissim, A. Lietoila, R.B. Gold, and J.F. Gibbons:J. Appl. Phys., 1980, vol. 51, pp. 274–79.

M. Davis, P. Kapadia, J. Dowden, W.M. Steen, and C.H.G. Courtney:J. Phys. D, Appl. Phys., 1986, vol. 19, pp. 1981–97.

S. Kou:Metall. Trans. A, 1982, vol. 13A, pp. 363–71.

S. Kou, D.K. Sun, and Y.P. Le:Metall. Trans. A, 1983, vol. 14A, pp. 643–53.

B.W. Gu, T.C. Ma, S.K. Brown, and L. Mannik:Mater. Sci. Technol., 1994, vol. 10, pp. 425–30.

P.H. Steen, P. Ehrhard, and A. Schüssler:Metall. Mater. Trans. A, 1994, vol. 25A, pp. 427–35.

M.F. Ashby and K.E. Easterling:Acta Metall., 1984, vol. 32, pp. 1935–48.

M. Bass:Physical Process in Laser Material Interaction, M. Bertolotti, ed., Plenum Press, New York, NY, 1983, ch. 3.

H.R. Shercliff and M.F. Ashby:Metall. Trans. A, 1991, vol. 22A, pp. 2459–66.

C. Hu and T.N. Baker:Acta Metall., 1995, vol. 43, pp. 3563–69.

T.J. Wieiting and J.T. Dchriempf:J. Appl. Phys., 1976, vol. 47 (9), pp. 4009–11.

Metals Reference Book, 5th ed., C.J. Smithells, ed., Butterworth, and Co., London, 1976.

Titanium Alloys, R. Boter, G. Welsch, and E.W. Collings, eds., ASM INTERNATIONAL, Materials Park, OH, 1994, p. 489.

T.R. Anthony and H.E. Cline:J. Appl. Phys., 1977, vol. 48, pp. 3888–94.

C. Chan, J. Mazumder, and M.M. Chen:Mater. Sci. Technol., 1987, vol. 3, pp. 306–11.

C. Hu, S. Mridha, H.S. Ubhi, A.W. Bowen, and T.N. Baker:Proc. 8th World Conf. on Titanium, Birmingham, United Kingdom, Oct. 1995, in press.

Handbook of Chemistry and Physics, 61st ed., R.C. Weast and M.J. Astle, eds., CRC Press, Boca Raton, FL, 1980.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hu, C., Baker, T.N. Investigation of the temperature field developed by a spinning beam in laser processing. Metall Mater Trans A 27, 4039–4047 (1996). https://doi.org/10.1007/BF02595653

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02595653