Abstract

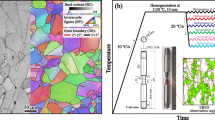

The environment-assisted cracking behavior of a Fe3Al intermetallic in an air moisture environment was studied. At room temperature, tensile ductility was found to be increased with strain rate, from 10.1 pct at 1×10−6 s−1 to 14.3 pct at 2 × 10−3 s−1. When tensile tests were done in heat-treated mineral oil on specimens that have been heated in the oil for 4 hours at 200°C, ductility was found to be recovered. These results suggest the existence of hydrogen embrittlement. Shear ligaments, which are ligament-like structures connected between microcracks, were observed on the tensile specimens. They undergo ductile fracture by shearing and enhance fracture toughness. This toughness enhancement (represented byJ l ) was estimated by a micromechanical model. The values of the unknown parameters, which are the average ligament length\(\bar l\), the area fractionV l , and the work-to-fractureτ 1 γ 1, were obtained from scanning electron microscopy (SEM) observation. The total fracture toughnessK c andJ l were reduced toward a slower strain rate. The experimental fracture toughness,K Q , was found to be increased with strain rate, from 35 MPa\(\sqrt m \) at 2.54×10−5 mm·s−1 to 47 MPa\(\sqrt m \) at 2.54×10−2 mm·s−1. The fact that strain rate has a similar effect onK Q andK c verifies the importance of shear ligament in determining fracture toughness of the alloy. With the presence of hydrogen, length and work-to-fracture of the shear ligament were reduced. The toughening effect caused by shear ligament was reduced, and the alloy would behave in a brittle manner.

Similar content being viewed by others

References

C.G. McKamey, J.H. DeVan, P.F. Tortorelli, and V.K. Sikka:J. Mater. Res., 1991, vol. 6, p. 1779.

C.T. Liu, C.G. McKamey, and E.H. Lee:Sripta Metall., 1990, vol. 24, p. 385.

A. Castagna and N.S. Stoloff:Scripta Metall., 1992, vol. 26, p. 673.

C.T. Liu and K.S. Kumar:J. Met., 1993, vol. 45 (5), p. 38.

N.S. Stoloff, M. Shea, and A. Castagna: inEnvironmental Effects on Advanced Materials, R.H. Jones and R.E. Ricker, eds., TMS, Warrendale, PA, 1991, p. 3.

A.G. Evans and J.W. Hutchinson:Acta Metall., 1989, vol. 37 (3), p. 909.

K.S. Chan:J. Met., 1992, vol. 44 (5), p. 30.

K.S. Chan:Metall. Trans. A, 1993, vol. 24A, pp. 569–83.

K.S. Chan:Metall. Trans. A, 1991, vol. 22A, pp. 2021–29.

J.R. Rice:J. Appl. Mech., 1960, vol. 35, p. 379.

D. Tromans:Acta Metall., 1994, vol. 42, p. 2043.

M.R. Louthan: inHydrogen in Metals, J.M. Bernstein and A. W. Thompson, eds., ASM, Champion, PA, 1973, p. 53.

J.P. Hirth:Metall. Trans. A, 1980, vol. 11A, p. 861.

J.A. Donovan: “Release of Hydrogen from Metals during Plastic Deformation,” paper presented at the Fifth Annual Spring Meeting, Institute of Metals Division, AIME, Philadelphia, PA, 1973.

C.T. Liu, C.L. Fu, E.P. George, and G.S. Painter:Iron Steel Inst. Jpn., 1991, vol. 31 (10), p. 1192.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chiu, H., Mao, X. Shear ligament phenomena in Fe3Al intermetallics and micromechanics of shear ligament toughening. Metall Mater Trans A 27, 3817–3825 (1996). https://doi.org/10.1007/BF02595631

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02595631