Abstract

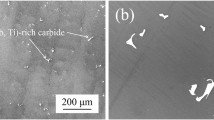

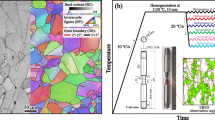

The effect of deformation temperature on tensile behavior of Inconel 718 alloy has been studied by a self-developed in-situ high-temperature tensile stage inside a scanning electron microscopy at a temperature range from room temperature (RT) to 750 °C. The dynamic microstructure evolution and mechanical properties at different temperatures were performed and compared by the uniaxial tensile tests. The in-situ test results showed that the mechanical properties and fracture mechanisms of Inconel 718 alloy were sensitive to deformation temperatures. From RT to 650 °C, the yield stress and ultimate tensile strength decrease slightly and the tensile ductility is comparable. While up to 750 °C, the yield stress and ultimate tensile strength decrease significantly, the elongation and reduction of cross section also showed a significant decrease from RT to 750 °C. It was found that at RT and 650 °C, tensile cracks tended to initiate around the carbide particles and the triple junctions of grain boundaries, also propagated transgranularly; at 750 °C, the cracks initiated at grain boundaries and propagated intergranularly. In fact, with the increase in deformation temperature, the fracture mechanism transformed from the ductile transgranular fracture to the brittle intergranular fracture.

Similar content being viewed by others

References

Dehmas M, Lacaze J, Niang A, Viguier B (2011) TEM study of high-temperature precipitation of delta phase in Inconel 718 alloy. Adv Mater Sci Eng 2011:1–9

Radhakrishna C, Rao KP (1997) The formation and control of Laves phase in superalloy 718 welds. J Mater Sci 32:1977–1984. https://doi.org/10.1023/A:1018541915113

Zhang HJ, Li C, Liu YC, Guo QY, Li HJ (2016) Precipitation behavior during high temperature isothermal compressive deformation of Inconel 718 alloy. Mater Sci Eng A 677:515–521

Chamanfar A, Sarrat L, Jahazi M, Asadi M, Weck A, Koul AK (2013) Microstructural characteristics of forged and heat treated Inconel-718 disks. Mater Des 52:791–800

Zhang HJ, Li C, Liu YC, Guo QY, Huang Y, Li HJ, Yu JX (2017) Effect of hot deformation on γ″ and δ phase precipitation of Inconel 718 alloy during deformation and isothermal treatment. J Alloy Compd 716:65–72

Chen YT, Yeh AC, Li MY, Kuo SM (2017) Effects of processing routes on room temperature tensile strength and elongation for Inconel 718. Mater Des 119:235–243

Zhang HJ, Li C, Guo QY, Ma ZQ, Huang Y, Li HJ, Liu YC (2018) Hot tensile behavior of cold-rolled Inconel 718 alloy at 650 °C: the role of δ phase. Mater Sci Eng A 722:136–146

Kitaguchi H (2012) Microstructure-property relationship in advanced Ni-based superalloys. Metallurgy - Advances in Materials and Processes, pp 20–21. https://doi.org/10.5772/52011

Oradei-Basile A, Radavich J (1991) Superalloys 718, 625, and various derivatives. In: Proceedings of the Minerals Metals and Materials Society, Pittsburgh. pp 325–335

Desvalle’es Y, Bouzidi M, Bois F, Beaude N, Loria EA (1994) Superalloy 718-metallurgy and applications, minerals, metals and materials society. Warrendale, PA 7:281–291

Warren J, Wei DY (2006) The cyclic fatigue behavior of direct age 718 at 149, 315, 454, and 538 °C. Mater Sci Eng A 428:106–115

Rai AK, Tripathy HP, Hajra RN, Raju S, Saibaba S, Jayakumar T (2016) Measurement of high temperature phase stability and thermophysical properties of alloy 740. Mater Sci Technol 32:488–497

Zhao SQ, Xie XS, Smith GD, Patel SJ (2003) Microstructural stability and mechanical properties of a new nickel-based superalloy. Mater Sci Eng A Struct Mater Prop Microstruct Process 355:96–105

Zhao YS, Zhang J, Song FY, Zhang M, Luo YS, Zhao H, Tang DZ (2020) Effect of trace boron on microstructural evolution and high temperature creep performance in Re-containing single crystal superalloys. Prog Nat Sci Mater Int 30:371–381

Liu BB, Han JQ, Zhao R, Liu W, Wan M (2016) Grain size effect on fracture behavior of the axis-tensile test of Inconel 718 sheet. High Temp Mater Proc 35:989–998

Wang Y, Shao WZ, Zhen L, Yang C, Zhang XM (2009) Tensile deformation behavior of superalloy 718 at elevated temperatures. J Alloys Compd 471:331–335

Lin YC, Deng J, Jiang YQ, Wen DX, Liu G (2014) Hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater Des 55:949–957

Zhao R, Li XJ, Wan M, Han JQ, Meng B, Cai ZY (2017) Fracture behavior of Inconel 718 sheet in thermal-aided deformation considering grain size effect and strain rate influence. Mater Des 130:413–425

Lu XD, Du JH, Deng Q (2013) In situ observation of high temperature tensile deformation and low cycle fatigue response in a nickel-base superalloy. Mater Sci Eng A 588:411–415

Andersson H, Persson C (2004) In-situ SEM study of fatigue crack growth behavior in IN718. Int J Fatigue 26:211–219

Boehlert CJ, Li H, Wang L (2010) Slip system characterization of Inconel 718 using in-situ scanning electron microscopy. Adv Mater Process 41–45

Ma JY, Lu JX, Tang L, Wang J, Sang LJ, Zhang YF, Zhang Z (2020) A novel instrument for investigating the dynamic microstructure evolution of high temperature service materials up to 1150 °C in scanning electron microscope. Rev Sci Instrum 91:043704

Lu JX, Chang L, Wang J, Sang LJ, Wu SK, Zhang YF (2018) In-situ investigation of the anisotropic mechanical properties of laser direct metal deposition Ti6Al4V alloy. Mater Sci Eng A 712:199–205

Zheng L, Schmitz G, Meng Y, Chellali R, Schlesiger R (2012) Mechanism of intermediate temperature embrittlement of Ni and Ni-based Superalloys. Crit Rev Solid State and Mater Sci 37:181–214

Sheng LY, Yang F, Guo JT, Xi TF (2014) Anomalous yield and intermediate temperature brittleness behaviors of directionally solidified nickel-based superalloy. Trans Nonferrous Metal Soc 24:673–681

Zhang SH, Zhang HY, Cheng M (2011) Tensile deformation and fracture characteristics of delta-processed Inconel 718 alloy at elevated temperature. Mater Sci Eng A 528:6253–6258

Rao GA, Kumar M, Srinivas M, Sarma DS (2003) Effect of standard heat treatment on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater Sci Eng A 355:114–125

Palumbo G, Aust KT (1995) Solute effects in grain boundary engineering. Canad Metall Q 34:165–173

Wang J, Zhang YF, Ma JY, Li JX, Zhang Z (2017) Microcrack nucleation and propagation investigation of Inconel 740H alloy under in situ high temperature tensile test. Acta Metall Sin 53:1627–1635

Lin YC, Li L, He DG, Chen MS, Liu GQ (2017) Effects of pre-treatments on mechanical properties and fracture mechanism of a nickel-based superalloy. Mater Sci Eng A 679:401–409

Chaturvedi MC, Han YF (1983) Strengthening mechanisms in Inconel 718 superalloy. Met Sci 17:145–149

Du BN, Hu ZY, Sheng LY, Cui CY, Yang JX, Zheng YF, Sun XF (2018) Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J Mater Sci Tech 34:1805–1816

Kumar J, Kumar A, Kumar V (2011) Ambient and high temperature in situ damage evolution in nickel based IN 718 superalloy. Mater Sci Eng A 528:4009–4013

Zhang WJ, Song XY, Hui SX, Ye WJ (2017) In-situ SEM observations of fracture behavior of BT25y alloy during tensile process at different temperature. Mater Des 116:638–643

Wang J, Lu JX, You XX, Ullah RF, Sang LJ, Chang L, Zhang YF, Zhang Z (2019) In-situ comparison of deformation behavior at 23 °C and 650 °C of laser direct melting deposited Ti–6Al–4V alloy. Mater Sci Eng A 749:48–55

Summers WD, Alabort E, Kontis P, Hofmann F, Reed RC (2016) In-situ high-temperature tensile testing of a polycrystalline nickel-based superalloy. Mater High Temp 33:338–345

Wang ZY, Wu SC, Kang GZ, Li H, Wu ZK, Fu YN, Withers PJ (2021) In-situ synchrotron X-ray tomography investigation of damage mechanism of an extruded magnesium alloy in uniaxial low-cycle fatigue with ratchetting. Acta Mater 211:116881

Liu ZG, Li PJ, Xiong LT, Liu TY, He LJ (2017) High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater Sci Eng A 680:259–269

Li XF, Zhang J, Fu QQ, Akiyama E, Song XL, Wang YF, Li QZ, Zou N (2018) Tensile mechanical properties and fracture behaviors of nickel-based superalloy 718 in the presence of hydrogen. Int J Hydrog Energy 43:20118–20132

Hrutkay K, Kaoumi D (2014) Tensile deformation behavior of a nickel based superalloy at different temperatures. Mater Sci Eng A 599:196–203

Alabort E, Barba D, Sulzer S, LiBner M, Petrinic N, Reed RC (2018) Grain boundary properties of a nickel-based superalloy: characterisation and modeling. Acta Mater 151:377–394

Rho BS, Nam SW, Xie X (2002) The effect of test temperature on the intergranular cracking of Nb-A286 alloy in low cycle fatigue. J Mater Sci 37:203–209. https://doi.org/10.1023/A:1013147319646

Ma XF, Shi HJ, Gu JL (2010) In-situ scanning electron microscopy studies of small fatigue crack growth in recrystallized layer of a directionally solidified superalloy. Mater Lett 64:2080–2083

Acknowledgements

This research was funded by Basic Science Center Program for Multiphase Media Evolution in Hypergravity of the National Natural Science Foundation of China (No. 51988101) and Key Projects of Beijing Natural Science Foundation (KZ202110005006).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sang, L., Lu, J., Wang, J. et al. In-situ SEM study of temperature-dependent tensile behavior of Inconel 718 superalloy. J Mater Sci 56, 16097–16112 (2021). https://doi.org/10.1007/s10853-021-06256-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06256-8