Abstract

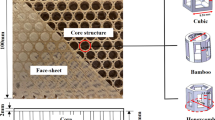

This present article deals with bending deformation and failure behavior of sandwich and multilayer beams composed of aluminum foam core and metallic face sheets analyzed byin-situ surface displacement analysis (SDA). The effect of beam structure on the failure mode of beam and the energy absorbed by beam failure were investigated and discussed. The SDA results revealed that collapse of the sandwich beams is by two basic modes, indentation (ID) and core shear (CS). The ID is localized deformation on the beam adjacent to the inner or outer roller in four-point bending, where displacement and compressive strains are at the maximum. As for CS mode, failure occurs in the core between inner and outer rollers, which corresponds to the maximum shear strain; discontinuous displacements in both the vertical and horizontal directions are the primary factors for shear crack initiation, growth, and broadening. The failure of the multilayer beams depends on whether the face sheets show ID mode or otherwise. If a single layer core sandwich fails in ID mode, the multilayer beams with similar face sheets show mixed ID + CS modes. If a single layer core sandwich fails fully in CS mode, no ID characteristic appears in the similar face sheet multilayer beams. The deformation energy of the beams relates strongly to the structure and geometry of beam. The predication of the bending fracture workW x of a beam is given by

whereW 5 is the deformation energy of the beam with a 5-mm core, andC is the thickness ratio of the corex to 5 mm.

Similar content being viewed by others

References

Y. Sugimura, J. Meyer, Y. He, H. Bart-Smith, J. Grenstedt, and A.G. Evens:Acta Mater., 1997, vol. 45 (12), pp. 5245–95.

T. Miyoshi, M. Itoh, S. Akiyama, and A. Kitahara:Adv. Eng. Mater., 2000, vol. 2 (4), pp. 179–83.

H. Bart-Smith, A.F. Bastawros, D.R. Mumm, A.G. Evans, D.J. Sypeck, and H.N.G. Wadley:Acta Mater., 1998, vol. 46 (10), pp. 3583–92.

A.F. Bastawros, H. Bart-Smith, and A.G. Evans:J. Mech. Phys. Solid, 2000, vol. 48, pp. 301–22.

Y. Sugimura, A. Rabiei, A.G. Evans, A.M. Harte, and N.A. Fleck:Mater. Sci. Eng., 1999, vol. A269, pp. 38–48.

L.J. Gibson and M.F. Ashby:Cellular Solids: Structure and Properties, 2nd ed., Cambridge University Press, Cambridge, United Kingdom, 1997.

O.B. Olurin, N.A. Fleck, and M.F. Ashby:Mater. Sci. Eng. A, 2000, vol. A291, pp. 136–46.

K.Y.G. McCullough, N.A. Fleck, and M.F. Ashby:Acta Mater., 1999, vol. 47 (8), pp. 2331–43.

A.M. Marte, N.A. Fleck, and M.F. Ashby:Acta Mater., 1999, vol. 47 (8), pp. 2511–24.

O.B. Olurin, K.Y.G. McCullough, N.A. Fleck, and M.F. Ashby:Int. J. Fatigue, 2001, vol. 23, pp. 375–82.

K.Y.G. McCullough, N.A. Fleck, and M.F. Ashby:Acta Mater., 1999, vol. 47 (8), pp. 2323–30.

V.S. Deshpande and N.A. Fleck:J. Mech. Phys. Solids, 2000, vol. 48, pp. 1253–83.

A.E. Simone and L.J. Gibson:Acta Mater., 1998, vol. 46 (6), pp. 2139–50.

A.E. Simone and L.J. Gibson:Acta Mater., 1998, vol. 46 (9), pp. 3109–23.

Y. Shen, F. Golnaraghi, and A. Plumtree:Int. J. Fatigue, 2001, vol. 23, pp. 491–97.

P.R. Onck, E.W. Andrews, and L.J. Gibson:Int. J. Mech. Sci., 2001, vol. 43, pp. 681–99.

E.W. Andrews, G. Gioux, P.R. Onck, and L.J. Gibson:Int. J. Mech. Sci., 2001, vol. 43, pp. 701–13.

H. Bart-Smith, J.W. Hutchinson, and A.G. Evans:Int. J. Mech. Sci., 2001, vol. 43, pp. 1945–63.

C. Chen, A.M. Harte, and N.A. Fleck:Int. J. Mech. Sci., 2001, vol. 43, pp. 1483–506.

A.M. Harte, N.A. Fleck, and M.F. Ashby:Int. J. Fatigue, 2001, vol. 23, pp. 499–507.

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.C. Wadley:Metal Foam: a Design Guide, Butterworth Heinemann, Oxford, United Kingdom, 2000.

Standard Test Method for Flexural Properties of Sandwich Constructions, ASTM Standard C393-94, ASTM, Warrendale, PA, 1998, pp. 21–24.

J.V. Mullin and A.C. Knoell:Mater. Res. Standards, 1970, vol. 10, pp. 16–20.

J.B. Sha: School of Materials Science & Engineering, Bei Hang University, Beijing, China, unpublished research.

J.B. Sha and T.H. Yip:Metall. Mater. Trans. A, 2005, vol. 36A, pp. 771–83.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sha, J.B., Yip, T.H. & Sun, J. Responses of damage and energy of sandwich and multilayer beams composed of metallic face sheets and aluminum foam core under bending loading. Metall Mater Trans A 37, 2419–2433 (2006). https://doi.org/10.1007/BF02586216

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02586216