Abstract

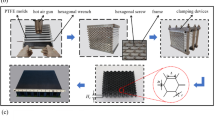

To improve the dynamic performance of sandwich panels, a bamboo bio-inspired core structural sandwich panel was designed, and two other general structures of sandwich panels, namely, cubic and honeycomb, were designed for comparison. These structural sandwich panels were manufactured using the fused deposition modeling technique. The dynamic responses of sandwich panels with different core structures under 5, 10, and 15 J of impact energy were evaluated and compared through low-velocity impact (LVI) tests. Finally, the non-destructive characterization method was employed to analyze the failure mechanism. Results indicate that the bamboo structural sandwich panels achieved maximum load capacity and absorbed the most energy among the three structural sandwich panels. The bamboo structure exhibited the best performance as the core structure of sandwich panels in resisting LVI. That is, the higher the impact energy and velocity are, the stronger and more brittle the sandwich are.

Similar content being viewed by others

References

S.K. Gummadi, A. Saini, J.S. Owusu-Danquah, and P. Sikder, Mechanical Properties of 3D-Printed Porous Poly-Ether-Ether-Ketone (PEEK) Orthopedic Scaffolds, Jom, 2022, 74, p 3379–3391. (in English)

N. Lumkemann, M. Eichberger, and B. Stawarczyk, Bonding to Different PEEK Compositions: The Impact of Dental Light Curing Units, Materials, 2017, 10(1), p 67. (in English)

A.D. Schwitalla, F. Botel, T. Zimmermann, M. Sutel, and W.D. Muller, The Impact of Argon/Oxygen low-Pressure Plasma on Shear Bond Strength Between a Veneering Composite and Different PEEK Materials, Dent. Mater., 2017, 33(9), p 990–994. (in English)

A.R. Zanjanijam, I. Major, J.G. Lyons, U. Lafont, and D.M. Devine, Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships, Polym. Basel, 2020, 12(8), p 1665. (in English)

A. El Magri, K. El Mabrouk, S. Vaudreuil, H. Chibane, and M.E. Touhami, Optimization of Printing Parameters for Improvement of Mechanical and Thermal Performances of 3D Printed Poly(Ether Ether Ketone) Parts, J. Appl. Polym. Sci., 2020, 137(37), p 49087. (in English)

J. Zheng, J. Kang, C. Sun, C. Yang, L. Wang, and D. Li, Effects of Printing Path and Material Components on Mechanical Properties of 3D-Printed Polyether-Ether-Ketone/Hydroxyapatite Composites, J. Mech. Behav. Biomed., 2021, 118, 104475. (in English)

B. Wang, S. Yu, J. Mao, Y. Wang, M. Li, and X. Li, Effect of Basalt Fiber on Tribological and Mechanical Properties of Polyether-Ether-Ketone (PEEK) Composites, Compos. Struct., 2021, 266, 113847. (in English)

P. Chen, J. Su, H. Wang, L. Yang, H. Cai, M. Li, and Y. Shi, Mechanical Properties and Microstructure Characteristics of Lattice-Surfaced PEEK Cage Fabricated by High-Temperature Laser Powder Bed Fusion, J. Mater. Sci. Technol., 2022, 125, p 105–117. (in English)

D. Garcia-Gonzalez, M. Rodriguez-Millan, A. Rusinek, and A. Arias, Investigation of Mechanical Impact Behavior of Short Carbon-Fiber-Reinforced PEEK Composites, Compos. Struct., 2015, 133, p 1116–1126. (in English)

S.A. Muhsin, P.V. Hatton, A. Johnson, N. Sereno, and D.J. Wood, Determination of Polyetheretherketone (PEEK) Mechanical Properties as a Denture Material, Saudi Dent. J., 2019, 31, p 382–391. (in English)

M.V. Hosur, M. Abdullah, and S. Jeelani, Manufacturing and Low-Velocity Impact Characterization of Hollow Integrated Core Sandwich Composites with Hybrid Face Sheets, Compos. Struct., 2004, 65, p 103–115. (in English)

M. Karahan, H. Gül, J. Ivens, and N. Karahan, Low Velocity Impact Characteristics of 3D Integrated Core Sandwich Composites, Text. Res. J., 2012, 82(9), p 945–962. (in English)

Y. Liu, W. Zhuang, and D. Wu, Performance and Damage of Carbon Fiber Reinforced Polymer Tubes Under Low-Velocity Transverse Impact, Thin Wall Struct., 2020, 151, 106727. (in English)

Y. Zhang, L. Yan, C. Zhang, and S. Guo, Low-Velocity Impact Response of Tube-Reinforced Honeycomb Sandwich Structure, Thin Wall Struct., 2021, 158, 107188. (in English)

M.S. Azmi, R. Hasan, R. Ismail, and N.A. Rosli, Static and Dynamic Analysis of FDM Printed Lattice Structures for Sustainable Lightweight Material Application, Prog. Indust. Ecol., 2018, 12(3), p 247–259. (in English)

G. Ye, H. Bi, L. Chen, and Y. Hu, Compression and Energy Absorption Performances of 3D Printed Polylactic Acid Lattice Core Sandwich Structures, 3D Print. Addit. Manuf., 2019, 6(6), p 333–343. (in English)

W. Liu, H. Song, Z. Wang, J. Wang, and C. Huang, Improving Mechanical Performance of Fused Deposition Modeling Lattice Structures by a Snap-Fitting Method, Mater. Des., 2019, 181, 108065. (in English)

A. Kumar, L. Collini, A. Daurel, and J.Y. Jeng, Design and Additive Manufacturing of Closed Cells from Supportless Lattice Structure, Addit. Manuf., 2020, 33, 101168. (in English)

J. Zheng, H. Zhao, E. Dong, E. Kang, J. Liu, C. Sun, and L. Wang, Additively-Manufactured PEEK/HA Porous Scaffolds with Highly-Controllable Mechanical Properties and Excellent Biocompatibility, Mater. Sci. Eng. C, 2021, 128, 112333. (in English)

D. Chen, Q. Luo, M. Meng, Q. Li, and G. Sun, Low Velocity Impact Behavior of Interlayer Hybrid Composite Laminates with Carbon/Glass/Basalt Fibers, Compos. Part B-Eng., 2019, 176, 107191. (in English)

D.S. Gemi, Ö.S. Şahin, and L. Gemi, Experimental Investigation of the Effect of Diameter Upon Low Velocity Impact Response of Glass Fiber Reinforced Composite Pipes, Compos. Struct., 2021, 275, 114428. (in English)

Y. Liu, W. Hu, R. Zhu, B. Safaei, B. Qin, and F. Chu, Dynamic Responses of Corrugated Cylindrical Shells Subjected to Nonlinear Low-Velocity Impact, Aerosp. Sci. Technol., 2022, 121, 107321. (in English)

C. Stephen, B. Shivamurthy, M. Mohan, A.H.I. Selvam, and B.H.S. Thimmappa, Low Velocity Impact Behavior of Fabric Reinforced Polymer Composites—A Review, Eng. Sci., 2022, 18, p 75–97. (in English)

H. Tuo, Z. Lu, X. Ma, J. Xing, and C. Zhang, Damage and Failure Mechanism of Thin Composite Laminates Under Low-Velocity Impact and Compression-After-Impact Loading Conditions, Compos. Part B-Eng., 2019, 163, p 642–654. (in English)

Q. Ma, H. Cheng, K.I. Jang, and H. Luan, A Nonlinear Mechanics Model of Bio-inspired Hierarchical Lattice Materials Consisting of Horseshoe Microstructures, J. Mech. Phys. Solids, 2016, 90, p 179–202. (in English)

C. Tan, J. Zou, S. Li, P. Jamshidi, A. Abena, and M.M. Attallah, Additive Manufacturing of Bio-inspired Multi-scale Hierarchically Strengthened Lattice Structures, Int. J. Mach. Tool Manuf., 2021, 167, 103764. (in English)

X. Gao, D.J. Zhu, S.T. Fan, and M.Z. Rahman, Structural and Mechanical Properties of Bamboo Fiber Bundle and Fiber/Bundle Reinforced Composites: A Review, J. Mater. Res. Technol., 2022, 19, p 2458–2469. (in English)

C.O. Ufodike, H. Wang, M.F. Ahmed, and G. Dolzyk, Design and Modeling of Bamboo Biomorphic Structure for In-Plane Energy Absorption Improvement, Mater. Des., 2021, 205, 109736. (in English)

Z. Sartip, E. Jayantha, F. Wahid, and J. Leng, Behavior of Continuous Fiber Composite Sandwich Core under Low-Velocity Impact, Thin Wall Struct., 2021, 158, 107157. (in English)

H. Imad, A. Ronald, X. Xiao, and M.D. Sangid, Comparing Non-destructive 3D X-ray Computed Tomography with Destructive Optical Microscopy for Microstructural Characterization of Fiber Reinforced Composites, Compos. Sci. Technol., 2019, 184, 107843. (in English)

D. Elena, N. Michele, D. Fabio, and M. Zarrelli, High Resolution X-ray Computed Tomography: A Versatile Non-destructive Tool to Characterize CFRP-Based Aircraft Composite Elements, Compos. Sci. Technol., 2020, 192, 108093. (in English)

A. Florence, M.A. Jaswin, and A.P. Pandi, Drop-Weight Impact Behavior of Hybrid Fiber/Epoxy Honeycomb Core Sandwich Composites under Hemi-Spherical Impactor, Fiber Polym., 2020, 21, p 1152–1162. (in English)

T. Iman and F. Abdolhossein, Non-destructive Evaluation of Damage Modes in Nanocomposite Foam-Core Sandwich Panel Subjected to Low-Velocity Impact, Compos. Part B-Eng., 2016, 103, p 51–59. (in English)

W.T. He, J.X. Liu, and B. Tao, Experimental and Numerical Research on the Low Velocity Impact Behavior of Hybrid Corrugated Core Sandwich Structures, Compos. Struct., 2016, 158, p 30–43. (in English)

J.J. Andrew, S.M. Srinivasan, and A. Arockiarajan, Parameters Influencing the Impact Response of Fiber-Reinforced Polymer Matrix Composite Materials: A Critical Review, Compos. Struct., 2019, 224, 111107. (in English)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wen, Z., Li, M., He, L. et al. Experimental Investigation of the Effect of Core Structures on Low-Velocity Impact Response of PEEK Sandwich Panels Manufactured by FDM. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09433-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09433-3