Abstract

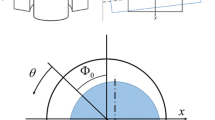

This paper represents a numerical iterative scheme for calculation of finite 360° journal bearings with longitudinal and transversal rough surfaces. A modified Christensen's Reynolds type equation is solved numerically under isothermal boundary condition. The Reynold's boundary condition assuming that the pressure and its derivative vanish near the point of location of the minimum film thickness is used in an iterative scheme to find out this location. Results of the analysis show the great influence of surface roughness on the bearing behaviour, especially when the bearing operates at its hydrodynamic limit.

Similar content being viewed by others

References

Tzeng, S.T., andE. Saibel: Surface roughness effect on slider lubrication. ASLE Trans. Vol. 10 (1967) pp. 334/38.

Christensen, H.: Stochastic models for hydrodynamic lubrication of rough surfaces. Proc. Instn. Mech. Engineers, Vol. 184, Pt. 1 (1969–1970) No. 55, pp. 1013/22.

Christensen, H., andK. Tønder: The hydrodynamic lubrication of rough bearing surfaces of finite width. ASME Trans. J. Lubr. Techn. Vol. 93 (1971) pp. 324/30.

Elrod, H.G.: Thin film lubrication theory for Newtonian fluids for surfaces possessing striated roughness or grooving. ASME Trans. J. Lubr. Techn. Vol. 95 (1973) pp. 484/89.

Rhow, S.K., andH.G. Elrod: The effects on bearing load carrying capacity of two sided striated roughness. ASME Trans. J. Lubr. Techn. Vol. 96 (1974) pp. 554/60.

Patir, N., andH.S. Cheng: An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. ASME Trans. J. Lubr. Techn. Vol. 100 (1978) pp. 12/17.

Patir, N., andH.S. Cheng: Application of average flow model to lubrication between rough sliding surfaces. ASME Trans. J. Lubr. Techn., Vol. 101 (1979) pp. 220/30.

Christensen, H., andK. Tønder: The hydrodynamic lubrication of rough journal bearings. ASME Trans. J. Lubr. Techn. Vol. 95 (1973), pp. 166/72.

Abdel-Latif, L.A., J. Frakash andH. Peeken: Analysis of a rough plain pad bearing of finite width. Forsch. Ing.-Wes. Vol. 50 (1984) No. 2, pp. 45/51.

Carnahan, P., H.A. Luther, andJ.O. Wilkes: Applied numerical methods. New York: John Wiley 1969.

Sauer, S.: Mathematische Hilfsmittel des Ingenieurs. Berlin, Heidelberg, New York: Springer Verlag 1969.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Abdel-Latif, L.A., Ammam, AM.A. Analysis of finite journal bearings with longitudinal and transversal rough surfaces. Forsch Ing-Wes 52, 111–116 (1986). https://doi.org/10.1007/BF02558448

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02558448