Abstract

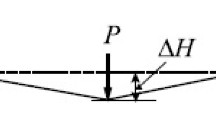

The microstructure, phase composition, room-temperature flexural strength, and fracture toughness of Al2O3−ZrO2−TiN (AZT) ceramics were studied on specimens annealed in air at 1000, 1200, and 1400°C. The strength of the ceramics decreased with annealing temperature. The degradation in strength was caused by defects formed on or near the surface of the ceramics during oxidation of TiN which started at 600–700°C. The surface defects after annealing are influenced by the formation of rutile (TiO2) at 1000 and 1200°C, aluminum titanate (Al2TiO5), and titanium suboxide Ti5O9 at 1400°C as well as by diffusion processes associated with ZrO2. If the annealing of smooth AZT specimens in air resulted in lower strength, specimens in the form of single-edge notched beam (SENB) exhibited a considerable increase in fracture toughness (K Ic) with annealing temperature. Such behavior was caused by the formation of an oxide layer which hindered the propagation of the main crack from the notch base. Thermal treatment of the smooth AZT specimens and further edge notching and testing did not result in a change of K Ic values. The Al2O3 and Al2O3−ZrO2 ceramics were also tested for comparison.

Similar content being viewed by others

References

N. Claussen, “Fracture toughness of Al2O3 with an unstabilized ZrO2 dispersed phase,”J. Am. Ceram. Soc.,59, No. 1-2, 49–51 (1976).

G. Orange, G. Fantozzi, P. Homerin, F. Thevenot, A. Leriche and F. Cambier, “Preparation and characterization of a dispersion toughened ceramic for thermomechanical uses (ZTA). Pt II: Thermomechanical characterization. Effect of microstructure and temperature on toughening mechanisms,”J. Eur. Ceram. Soc.,9, No. 3, 177–185 (1992).

A. Bellosi, G. de Portu, and S. Guicciardi, “Preparation and properties of electroconductive Al2O3-based composites,”J. Eur. Ceram. Soc.,10, No. 4, 307–315 (1992).

Yu. Gogotsi, O. Grigor’ev, N. Orlovskaya, D. Ostrovoi, and V. Yaroshenko, “Toughened Al2O3-based ceramics,”Ogneupory, No. 11, 10–13 (1989).

Z. S. Rak and P. J. van Tilborg, “Effect of TiN and SiC on the mechanical properties of ZTA ceramics,” in: P. Duran and J. F. Fernandez, eds., Third Euro-Ceramics, Vol. 3, Faenza Editrice Iberica S. L., Faenza, Spain (1993), pp. 767–772.

T. Arahori, T. Suzuki, N. Iwamoto, and N. Umesaki, “Transformation behaviour of ZrO2 in Al2O3−ZrO2 composites,” in: S. Somia, N. Yamamoto and H. Yanagida, eds,Advances in Ceramics, Vol. 24, Science and Technology of Zirconia III, The American Ceramic Society, Inc., Westerville, Ohio (1988), pp. 549–558.

D. Basu, S. Chatterjee, M. K. Sinha, and M. K. Basu, “Effect of grinding and subsequent annealing on the properties of transformation-toughened alumina ceramics,”J. Mater. Sci. Lett.,11, No. 9, 564–566 (1992).

G. A. Gogotsi, “Test methods of advanced ceramics—reasonable approaches to certification of ceramics,”Key Eng. Mater.,56–57, 419–434 (1991).

N. Orlovskaya, G. Krivoshei, O. Babii, and D. Ostrovoi, “Effect of annealing on microstructure, phase composition, and failure of Al2O3−ZrO2 ceramics at room temperature,”J. Mater. Sci. Lett.,15, No. 2, 166–169 (1996).

F. F. Lange, “Compressive surface stresses developed in ceramics by an oxidation-induced phase change,”J. Am. Ceram. Soc.,63, No. 1, 38–42 (1980).

Yu. G. Gogotsi and V. A. Lavrenko,Corrosion of High-Performance Ceramics, Springer Verlag, Berlin (1992).

Yu. Gogotsi, F. Porz, and V. Yaroshenko, “Mechanical properties and oxidation behaviour of Al2O3−AlN−TiN composites,”J. Am. Ceram. Soc.,75, No. 8, 2251–2259 (1992).

A. Tampieri, E. Landi, and A. Bellosi, “The oxidation behaviour of monolithic TiN ceramics,”Br. Ceram. Trans. J.,90, No. 6, 194–196 (1991).

R. F. Voitovich,Oxidation of Carbides and Nitrides [in Russian], Naukova Dumka, Kiev (1981).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 1, pp. 132–138, January–February, 1999.

Rights and permissions

About this article

Cite this article

Ostrovoi, D.Y., Orlovskaya, N.A., Kovylyaev, V.V. et al. Effect of annealing on the microstructure, room-temperature strength, and fracture toughness of Al2O3−ZrO2−TiN ceramics. Strength Mater 31, 99–103 (1999). https://doi.org/10.1007/BF02509746

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02509746