Abstract

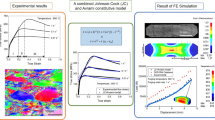

In this paper, the proposed is a quasi-flow constitutive model with strain-rate sensitivity for elastic plastic large deformation. The model is based on the Quasi-flow Corner theory, and is suitable for the sheet metal forming process simulation with a variable punch machine velocity. Uniaxial tensile tests and deep-drawing tests of a circular blank with square punch are carried out and numerically simulated. The consistency between the experimental and the numerically simulated results shows the validity of the present new constitutive model.

Similar content being viewed by others

References

Park JJ, Oh SI, Altan T. Analysis of axisymmetric sheet forming processes by rigid-viscoplastic finite element method.Trans ASME J Engng Ind, 1987, 109: 347–356

Germain Y, Chung K, Wagoner RH. A rigid-viscoplastic finite element program for sheet metal forming analysis.Int J Mech Sci, 1989, 31: 1–12

Chandra A. A generalized finite element analysis of sheet metal forming with an elastic-viscoplastic material model.Trans ASME, J Engng Ind, 1986, 108: 9–16

Hart EW. Constitutive relations for the nonelastic deformation of metals.Trans ASME, J Engng Mater Technol, 1976, 193:13–21

Huang YH, Liu CH. The effects of strain rate and anisotropy upon the sheet-stretching process.Int J Mech Sci, 1994, 36(4): 105–113

Budiansky B. A reassessment of deformation theories of plasticity.Trans ASME, J Appl Mech, 1959. 259–269

Storen S, Rice JR. Localized necking in the sheet.J Mech Phys Solids, 1975, 23: 421–435

Hutchinson JW. Plasticity buckling.Advances Appl Mech, 1974, 14: 67–84

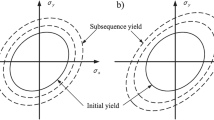

Christofferson J, Hutchinson JW. A class of Phenomenological corner theoreis of Plasticity.J Mech Phys Solids, 1979, 27: 465–476

Hu P, Na JX, Li DY. Bifurcation and post bifurcation behavior in sheet metal tension with strong anisotropy.J Mater Proc Tech, 1998, 74: 276–285

Hu P, Lian J, Liu YQ, et al. A quasi-flow corner theory of elastic plastic finite deformation,Int J Solids Struct, 1998, 35(15): 1827–1845

Hu P, Liu YQ, Wang JC. Numerical study of the flange earring of deep-drawing sheets with stronger anisotropy.Int J Mech Sci, 2001, 43: 279–288

Li DY, Hu P, Cao Y, et al. Section analysis of industrial sheet-metal stamping processes.J Mater Proc Tech, 2002, 120: 37–45

Chen WJ, Cheung YK. Refine quadrilateral element based on Mindlin/Reissner plate theory.Int J Num Meth Eng, 2000, 47: 605–613

Simunovic S, Shaw J. Effect of strain rate and material processing in full vehicle crash analysis. ASE Technical Paper, 2000, 1: 2715–2728, Society of Automotive Engineers, Warrendale, PA, USA

Engl B, Drewes EJ. New high strength steels with good formability for automotive applications. ATS Conf, Paris, Dec, 2000. 125–133

Penazzi L, Di Pasquale E, Aita S, et al. Material characterization for the CAE finite element simulation of sheet material forming. In: Proc 17th IDDRG Congr, Shenyang, China, 1992. 149–156

Nagtegaal JC, Jong JE.Int J Num Meth Engng, 1981, 17: 51–67

Author information

Authors and Affiliations

Additional information

The project supported by the Scientific Foundation of National Outstanding Youth of China (10125208), the National Natural Science Foundation of China (19832020), and the National Education Committee of China

Rights and permissions

About this article

Cite this article

Ping, H., Guozhe, S. & Guang, Y. A quasi-flow constitutive model with strain-rate dependence. Acta Mech Sinica 20, 283–291 (2004). https://doi.org/10.1007/BF02486720

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02486720