Conclusions

-

1.

Cracks that appear in soldering materials of different kind are a result of the simultaneous action of the appearing tensile stresses and the solder melt.

-

2.

The appearance of tensile stresses in soldering is connected with the volume changes; in alloy ÉP202 they are caused by intensification of the decomposition of the solid solution accompanied by the segregation of particles of fine disperse phases and in steel VNS16 they are caused by the segregation of particles of carbide phases and the α→γ transformation. In addition, the appearance of stresses in a specific temperature range is promoted by technological factors, coarse grains, the deformation rate, the presence of hydrogen, etc.

-

3.

The tensile stresses intensify the decomposition of the solid solution accompanied by segregation of hardening phases and their coarsening, especially over grain boundaries.

-

4.

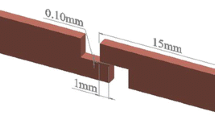

A crack appearing in materials during soldering has a wedge shape and a sharp notch in the frontal plane; its growth has an intercrystalline nature. The propagating cracks branch due to the pores and cracks appearing in the volume of the metal.

-

5.

The growth of cracks in soldering occurs from the surface and in the bulk of the material. The growth of a crack from the surface is characterized by jumps due to the repeated processes of accumulation and consumption of elastic energy at the tip of the crack when it propagates and stops respectively.

-

6.

Corrosion and diffusion processes develop in the zone of surface cracks. The corrosion process is characterized by selective dissolution of nickel, which forms the base of alloy ÉP202 and is an alloying element in steel VNS16, in the liquid solder. The diffusion process is characterized by predominant penetration of copper into the lattice of the materials. Corrosion and diffusion are not observed in fracture zones in the bulk of the specimens.

Similar content being viewed by others

References

V. N. Semenov,Liquid-Metal Embrittlement of High-Strength Alloys in Their Interaction with Copper-Silver Solder: and a Soldering Technology of LPRE. Author's Abstract of Candidate's Thesis [in Russian], Moscow (1987).

V. N. Semenov, “Diploma for Invention No. 88, Priority: Nov. 1991,”Bull. VAK Rossii, No. 2, 43–46 (1998).

R. Cahn (ed.),Physical Metallurgy, Amsterdam (1965).

Additional information

Translated from Metallovedenic i Termicheskaya Obrabotka Metallov, No. 10, pp. 17–19, October, 1999.

Rights and permissions

About this article

Cite this article

Semenov, V.N. Special features of fracture in materials used for soldering structures. Met Sci Heat Treat 41, 438–440 (1999). https://doi.org/10.1007/BF02469094

Issue Date:

DOI: https://doi.org/10.1007/BF02469094