Abstract

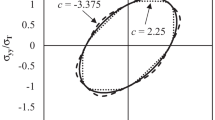

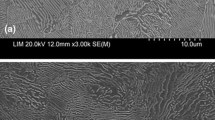

Conventional methods for constructing yield loci rely on the assumption that nonlinear strains are permanent strains, which is not always the case. A nickel-base alloy, SiC fiber-reinforced titanium, an aluminum alloy, and particlereinforced aluminum have been observed to violate this assumption. We present a method for constructing yield loci using a proof strain criterion for the permanent strain that relies on cyclic, proportional, probes of the yield surface. Two criteria are implemented: one for stress reversal and one for yielding. The method is demonstrated by the construction of initial and subsequent yield loci in the axial-shear stress plane using thin-walled tubular specimens. Results are presented for 6061-T6 aluminum as well as for 6092/SiC/17.5p-T6, which is 6092 aluminum reinforced with 17.5 volume percent silicon carbide particulate. The centers of the initial yield loci for the composite are eccentric to the origin of the stress plane most likely because of the residual stresses induced during processing. Material hardening due to multiaxial stress states can be described by tracking evolution of the subsequent yield surfaces and here hardening of the particulate composite was primarily kinematic

Similar content being viewed by others

Abbreviations

- D o, Di :

-

outer and inner diameters

- P :

-

axial force

- T :

-

torque

- ɛ-45, ɛ0, ɛ45 :

-

normal strains measured by rosette

- E 1, Eu :

-

Young's modulus

- G l, Gu :

-

shear modulus

- σ l, σu :

-

axial stress axis intercept

- τ l, τu :

-

shear stress axis intercept

- σ c, τc,a,b:

-

post-processed ellipse parameters

- etv :

-

target value equivalent strain (proof strain)

- e th :

-

threshold equivalent strain

- Δσe :

-

equivalent stress increment

- Θ:

-

probe angle

- στ:

-

axial and shear stress

- εγ:

-

axial and shear strain components

- ɛ off,γ off,e off,ɛ off,γ off,e p :

-

offset and plastic strain components

- ⁛ cor :

-

axial offset strain correction; for compression only

- σ max :

-

maximum equivalent stress in a cycle of a probe

- σ0,τ0 :

-

center of yield surface probe pattern

- s ij :

-

deviatoric stress tensor

- ɛ pij :

-

plastic strain tensor

References

Sun, L.Z. Ju, J.W. andLiu, H.T., “Elastoplastic Modeling of Metal Matrix Composites with Evolutionary Particle Debonding,”Mechanics of Materials,35,559–569 (2003).

Ahmad, J., Newaz, G.M. andNicholas, T., “Analysis of Characterization Methods for Inelastic Composite Material Deformation under Multiaxial Stress,” Multiaxial Fatigue and Deformation: Testing and Prediction, ASTM-STP 1387, S. Kalluri andP.J. Bonacuse, editors, American Society for Testing and Materials, West Conshohocken, PA, 41–53 (2000).

Li, M., Ghosh, S. andRichmond, O., “An Experimental-Computational Approach to the Investigation of Evolution in Discontinuously Reinforced Aluminum Matrix Composites,”Acta Materialia,47,3515–3532 (1999).

Lissenden, C.J., Arnold, S.M. andIyer, S.K., “Flow/Damage Surfaces for Fiber-Reinforced Metals Having Different Periodic Microstructures,”International Journal of Plasticity,16,1049–1074 (2000).

Lissenden, C.J. andArnold, S.M., “Theoretical and Experimental Considerations in Representing Macroscale Flow/Damage Surfaces for Metal Matrix Composities”International Journal of Plasticity,13,327–358 (1997).

Lode, W., “Versuche über den Einfluss der mittleren Hauptspannung auf das Fliessen der Metalle, Eisen, Kupfer, und Nickel,”Zeitscrift für Physik,36,913–939 (1926).

Taylor, G.I. andQuinney, H., “The Plastic Distortion of Metals,”Philosophical Transactions of the Royal Society (London) Series A,230,323–362 (1937).

Tresca, H.E., “Sur l'écoulement des corps solides soumis á de fortes pressions,”Comptes Rendus de l'Académie des Sciences (Paris),59,754 (1864).

von Mises, R., “Mechanik der festen Körper im plastisch deformablen Zustand,” Nachrichten der Gesellschaft der Wissenschaften in Göttingen, Mathematisch Physikalische Klasse, 582–592 (1913).

Hill, R., The Mathematical Theory of Plasticity, Oxford University Press, London (1950).

Hecker, S.S., “Experimental Studies of Yield Phenomena in Biaxially Loaded Metals,”Constitutive Equations in Viscoplasticity: Computational and Engineering Aspects, AMD-Vol. 20, J.A. Stricklin andK.J. Saczalski, editors,ASME, New York, 1–33 (1976).

Michno, M.J. andFindley, W.N., “An Historical Perspective of Yield Surface Investigations For Metals,”International Journal of Nonlinear Mechanics,11,59–82 (1976).

Liu, K.C. andGreenstreet, W.L., “Experimental Studies to Examine Elastic-Plastic Behavior of Metal Alloys Used in Nuclear Structures,”Constitutive Equations in Viscoplasticity: Computational and Engineering Aspects, AMD-Vol. 20, J.A. Stricklin andK.J. Saczalski, editors ASME, New York, 35–56 (1976).

Phillips, A., “A Review of Quasi-Static Experimental Plasticity and Viscoplasticity,”International Journal of Plasticity,2,315–328 (1986).

Helling, D.E., Miller, A.K. andStout, M.G., “An Experimental Investigation of the Yield Loci of 1100-0 Aluminum, 70:30 Brass, and an Overaged 2024 Aluminum Alloy After Various Prestrains,”Journal of Engineering Technology,108,313–320 (1986).

Dvorak, G.J., Bahei-El-Din, Y.A., Macheret, Y. andLiu, C.H., “An Experimental Study of Elastic-Plastic Behavior of a Fibrous Boron-Aluminum Composite,”Journal of the Mechanics and Physics of Solids,36,655–687 (1988).

Wu, H.C. andYeh, W.C., “On the Experimental Determination of Yield Surfaces and Some Results of Annealed 304 Stainless Steel,”International Journal of Plasticity,7,803–826 (1991).

Khan, A. andWang, X., “An Experimental Study on Subsequent Yield Surface After Finite Shear Prestraining,”International Journal of Plasticity,9,889–905 (1993).

Gil, C.M., Lissenden, C.J. andLerch, B.A., “Yield of Inconel 718 by Axial-Torsional Loading at Temperatures up to 649°C,”Journal of Testing and Evaluation,27,327–336 (1999).

Lissenden, C.J., Lerch, B.A., Ellis, J.R. andRobinson, D.N., “Experimental Determination of Yield and Flow Surfaces Under Axial-Torsional Loading,”Multiaxial Fatigue and Deformation Testing Techniques, ASTM STP 1280, S. Kalluri andP.J. Bonacuse, editors American Society for Testing and Materials, West conshohocken, PA, 92–112 (1997).

Gil, C.M., Lissenden, C.J. andLerch, B.A., “Unusual Response of Some Metallic Materials,”Mechanics of Materials,31,565–577 (1999).

Hirth, J.P. andCohen, M., “On the Strength-Differential Phenomenon in Hardened Steel,”Metallurgical Transactions,1,3–8 (1970).

Arsenault, R.J. andTaya, M., “Thermal Residual Stress in Metal Matrix Composite,”Acta Metallurgica,35,651–659 (1987).

Arsenault, R.J. andWu, S.B., “The Strength Differential and Bauschinger Effects in SiC−Al Composites,”Material Science and Engineering A,96,77–88 (1987).

Lubliner, J., Plasticity Theory, Macmillan, New York (1990).

Shen, H. andLissenden, C.J., “3D Finite Element Analysis of Particle-Reinforced Aluminum,”Material Science and Engineering A,338,271–281 (2002).

Lei, X. andLissenden, C.J., “Tensile, Compressive, and Shear Response of a Particulate Reinforced Aluminum Composite,”composite Materials: Testing and Design Fourteenth Volume, ASTM STP 1436, American Society for Testing and Materials, C.E. Bakis, editor West Conshohoken, PA, 255–272 (2003).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lissenden, C.J., Lei, X. A more comprehensive method for yield locus construction for metallic alloys and composites. Experimental Mechanics 44, 10–20 (2004). https://doi.org/10.1007/BF02427970

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02427970