Abstract

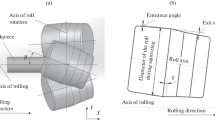

In this paper we describe an experimental technique developed to measure the deformation gradients and temperature in a single hot rolling pass of an AA3004 sample that was fitted with an insert. The insert had been previously hand engraved with a 1×1 mm grid pitch, and the analysis of the data digitally captured from the image of the deformed grid enabled the calculation of the components of the deformation gradient tensor. Four steel pins prevented relative motion between the insert and the rest of the sample. No detachment was observed between insert and sample after rolling. The temperature was measured during rolling using two embedded thermocouples, one close to the surface and the other in the centerline. The commercial finite element code ABAQUS was used to create a three-dimensional model of the rolling process. The recorded temperature was compared to the numerical values evaluated after tuning the heat transfer coefficient. The shape of the grid after rolling was checked against the deformed mesh using different fricition coefficients in order to obtain the optimum match. The unusually large length of the insert enabled the rolling process to be stopped halfway so that a picture of the roll-gap area could be obtained. This provided a partially deformed grid that represented the transient state during rolling. The experimentaily determined deformation gradient in this area as well as in the steady-state area agreed well with the finite element oredictions.

Similar content being viewed by others

References

Kocks, U.F. et al., editors, Texture and Anisotropy, Cambridge University Press, Cambridge (1998).

Basar, Y. and Weichert, D., editors, Nonlinear Continuum Mechanics of Solids, Springer-Verlag, Berlin (2000).

Wells, M.A., Lloyd, D.J., Samarasekara, I.V., Brimacombe J.K., and Hawbolt, E.B., Metallurgical and Materials Transactions B,29b,709–719 (1998).

Puchi, E.S., Beynon, J., and Sellars, C.M., Proceedings of the International Conference on Physical Metallurgy of Thermomechanical Processing of Steels and other Materials (Thermec 88), I. Tamura editor, Tokyo, Iron and Steel Institute of Japan, 572–579 (1988).

Timothy, S.P., Yiu, H.L., Fine, J.M., and Ricks, R.A., Materials Science and Technology,7,255–261 (1991).

Lenard, J.G., Pietrzyk, M., and Cser, L., Mathematical Simulation of the Properties of Hot Rolled Products. Elsevier, Oxford, (1999).

Proceedings of Modelling of Metal Forming Processes 3, London, UK, December 13–15 (1999).

Beynon, J.H., Higginson, R.L., and Pinna, C., “Rolling Experiments, Texture Measurements and Computer-based Predictions: Closing the Loop,” Proceedings of the Conference of Metallurgists. Thermomechanical Processing of Steel, Ottawa, Canada, August, 121 (2000).

Wells, M.A., Maijer D.M., Jupp, S. Lockhart G., andVan Der Winder M.RI, Materials Science and Technology,19,467–475 (2003).

Li, E.B., Tieu, A.K., andYuen, W.Y.D., “Application of Digital Image Correlation Technique to Dynamic Measurement of the Velocity Field in the Deformation Zone in Cold Rolling,” Optics and Lasers in Engineering,39,479–488 (2003).

Colonna, L., Dimitriou, R. Pinna, C., and Zhu, Q., “Measurement of Local Strain Heterogeneity in AA5182 after Hot Rolling Deformation,” Aluminium, October, 393–397 (2003).

Das, S., Palmiere, E., andHoward, I.C., “Effect of Friction on Deformation During Rolling as Revealed by Embedded Pin Technique,” Material Science and Technology,17, 865–873 (2001).

Shi, H., Sellars, A.J., Shahani, R., andBolingbrode, R., “Constitutive Equations for High Temperature Flow Stress Aluminum Alloys,” Material Science and Technology,13,210–216 (1997).

Mielnik, E.M., Metalworking Science and Engineering, McGraw-Hill, New York (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Boldetti, C., Pinna, C., Howard, I.C. et al. Measurement of deformation gradients in hot rolling of AA3004. Experimental Mechanics 45, 517–525 (2005). https://doi.org/10.1007/BF02427905

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02427905