Abstract

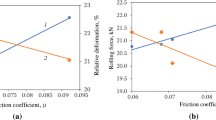

A new estimation procedure for estimating the influence of rapid strengthening on the strain resistance is proposed using a 6061 aluminum alloy (AD33, 1330) as an example. To implement this procedure, it is suggested to mathematically process the data of a system for monitoring a hot rolling mill. Attention is paid to the fact that the roll force in each pass increases with the rolling speed. On the basis of the determined strain resistance at a known roll force, it is possible to plot strain resistance as a function of the rolling speed. It has been revealed that the results of data processing are reliable for roll passes from 6 to 12, which is confirmed by the results of dispersion analysis. The obtained results have been compared with the published laboratory data, and they are found to agree with each other. The results obtained can be applied for everyday operation of rolling-mill shops.

Similar content being viewed by others

References

P. I. Polukhin, G. Ya. Gun, and A. M. Galkin, Plastic Deformation Resistance of Metals and Alloys (Metallurgiya, Moscow, 1983).

S. A. Bozhko, S. Ya. Betsofen, Yu. R. Kolobov, and T. N. Vershinina, “Formation of the structure and properties of an Mg–Al–Zn–Mn alloy during plastic deformation by rolling,” Russian Metallurgy (Metally), No. 3, 211–217 (2015).

A. Yu. Churyumov, A. I. Bazlov, A. A. Tsar’kov, and A. V. Mikhailovskaya, “Investigation into the structure and properties of wrought Al–Mg–Mn alloy using Gleeble 3800 simulating complex of thermomechanical processes,” Metallurg, No. 8, 76–80 (2012).

A. I. Tselikov, A. D. Tomlenov, V. I. Zyuzin, A. V. Tret’yakov, and G. S. Nikitin, Theory of Rolling: A Handbook (Metallurgiya, Moscow, 1982).

V. L. Bereznoi, “Substantiation and estimation of approaches to further development of basic pressing technologies,” Tekhnol. Legk. Splavov, No. 4, 81–91 (2012).

V. V. Zakharov, “Structural strengthening of aluminum alloys,” Tekhnol. Legk. Splavov, No. 4, 18–24 (2011).

V. I. Elagin, “On structural strengthening of aluminum alloys,” Tsvetn. Met., Nos. 5–6, 134–140 (2005).

Yu. N. Loginov, “Analysis of energy consumption upon hot rolling of aluminum sheet semifinished items,” Proizvod. Prokata, No. 4, 19–24 (2005).

A. I. Tselikov, G. S. Nikitin, and S. E. Rokotyan, Theory of Longitudinal Rolling: A Handbook (Metallurgiya, Moscow, 1980).

A. Hensel und Th. Spittel, Kraft- und Arbeitsbedarf bildsamer Formgebungsverfahren (Deutscher Verlag für Grundstoffindustrie, Leipzig, 1978).

Yu. N. Loginov and M. Yu. Seredkina, “Investigation into rapid rolling of aluminum alloy slab using finitie element method,” Tekhnol. Legk. Splavov, No. 3, 121–126 (2015).

Yu. N. Loginov and O. F. Degtyareva, “Influence of deformation rate on structural strengthening of pressed pipes made of 6061 aluminum alloy,” Tekhnol. Legk. Splavov, No. 4, 123–127 (2007).

E.M. Herba and H.J. McQueen, “Influence of particulate reinforcements on 6061 materials in extrusion modeling,” Mater. Sci. Eng. A 372, 1–14 (2004).

S. P. Burkin, N. A. Babailov, and V. V. Ovsyannikov, Deformation Resistance of Al and Mg Alloys: A Handbook (UrFU, Yekaterinburg, 2010).

Xueling Fan, Tao Suo, Qin Sun, and Tiejun Wang, “Dynamic mechanical behavior of 6061 Al alloy at elevated temperatures and different strain rates,” Acta Mechan. Solida Sinica. 26 (2), 111–120 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.N. Loginov, M.A. Golovnin, 2017, published in Metally, 2017, No. 2, pp. 33–38.

Rights and permissions

About this article

Cite this article

Loginov, Y.N., Golovnin, M.A. Technique of determining the parameters of rapid strengthening of an aluminum alloy during hot rolling. Russ. Metall. 2017, 188–192 (2017). https://doi.org/10.1134/S0036029517030053

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029517030053