Abstract

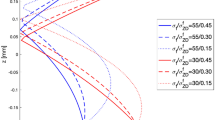

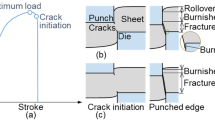

A method for the experimental determination of the through-thickness residual stress distribution in paperboard is presented. The successive removal of thin layers from strips of board through surface grinding changes the stress-state and the bending stiffness resulting in a changed curvature, which is measurable. From tests of strips in both in-plane directions, stress distributions can then be evaluated using the Treuting-Read method. Geometrically nonlinear effects at the large deformations taking place are avoided through a proper choice of strip dimensions. Typical results are presented and factors influencing the accuracy of the determination are thoroughly discussed.

Similar content being viewed by others

References

Lu, J., editor, Handbook of Measurement of Residual Stresses, Society for Experimental Mechanics, Prentice-Hall, Upper Saddle River, NJ (1996).

Underwood, J.H., “Residual-stress Measurement Using Surface Displacements Around an Indentation,” EXPERIMENTAL MECHANICS,13,373–380 (1973).

Waterhouse, J.F., Stera, S., andBrennan, D., “Z-direction Variation of Internal Stress and Properties in Paper,”Journal of Pulp and Paper Science,13 (1),J33-J37 (1987).

Waterhouse, J.F., “Residual Stresses in Paper and Board,”Handbook of Physical and Mechanical Testing of Paper and Paperboard, Mark, R.E. et al., editors, Marcel Dekker, New York (2002).

Sunderland, P., Sollander, A., Månsson, J.-A., andCarlsson, L.A., “Measurement of Process-induced Residual Stresses in Linerboard,”Journal of Pulp and Paper Science,25 (4),130–136 (1999).

Östlund, M., Östlund, S., Carlsson, L.A., andFellers, C., “The Influence of Drying Restraints and Beating Degree on Residual Stress Build-up in Paperboard,”Journal of Pulp and Paper Science,30 (11),289–293 (2004).

Östlund, M., Östlund, S., Carlsson, L.A., andFellers, C., “The Influence of Drying Conditions on Residual Stress Build-up in Paperboard,”Journal of Pulp and Paper Science,30 (11),312–316 (2004).

Schultz-Eklund, O., Fellers, C., and Johansson, P.-Å., “Method for the Local Determination of the Thickness and Density of Paper,” 1991 International Paper Physics Conference, Kona, HI, 511–523 (1991).

Treuting, R.G. andRead, W.T. Jr., “A Mechanical Determination of Biaxial Residual Stress in Sheet Materials,”Journal of Applied Physics,22 (4),130–134 (1951).

Baum, G.A., Brennan, D.C., andHabeger, C.C., “Orthotropic Elastic Constants of Paper,”Tappi Journal,64 (8),97–101 (1981).

Nordström, A., Gudmundson, P., andCarlsson, L.A., “Influence of Sheet Dimensions on Curl of Paper,”Journal of Pulp and Paper Science,24 (1),18–25 (1998).

Lysaght, J., Sheet Steel Fabrication Handbook, John Lysaght Ltd, Port Kembla, Australia (1983).

Paterson, M.W.A. andWhite, W.T. Jr., “Layer Removal Analysis of Residual Stress. Part 2: A New Procedure for Polymer Moldings with Depthvarying Young's Modulus,”Journal of Materials Science,24,3521–3528 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Östlund, M., Östlund, S., Carlsson, L.A. et al. Experimental determination of residual stresses in paperboard. Experimental Mechanics 45, 493–497 (2005). https://doi.org/10.1007/BF02427902

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02427902