Abstract

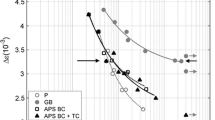

Fatigue tests in reversed torsion were run on 2024-T351 aluminum alloy specimens in (1) uncoated state, (2) anodized with 0.1-mil (0.0025-mm) coating and (3) chromate conversion coating. Tests on all three groups were run at low (20–25 percent), medium (55–60 percent), and high (86–91 percent) relative humidity. Tests were run at stress levels of 90, 117, 138 MPa (13,000, 17,000, and 20,000 psi).

Results of test on anodized and on uncoated specimens showed no effect due to a change in relative humidity. Chromate coating showed an effect on fatigue life at low humidity but showed no effect at medium or at high humidity. The anodized coating caused a decrease in fatigue life when compared to uncoated specimens.

Similar content being viewed by others

References

Lorkovic, W.M., Varallyay, D. andDaniels, R.D., “Corrosion Fatigue of Aluminum Alloys,”Materials Protection and Performance,3 (11),16–23 (Nov. 1964).

Takeuchi, K., Tanaka, E. andSuzuki, T., Sumitomo Light Metal Tech. Reports,11 (1),77–81 (Jan. 1970). (Text in Japanese, abstract in English.)

Beitel, G.A. andBowles, C.Q., “Influence of Anodic Layers on Fatigue-Crack Initiation in Aluminum,”Metal Sci. J.,5,85–91 (May 1971).

Hahn, G.T. andSimon, R., “Review of Fatigue Crack Growth in Aluminum Alloys,”Engrg. Frac. Mech.,5 (3),523–540 (Sept. 1973).

Womack, E.F., Wilson, J.H. andMabie, H.H., “Torsional Fatigue Tests of Anodized Aluminum Rods,”Experimental Mechanics,16 (10),361–368 (Oct. 1976).

Frankel, H.E., Bennett, J.A. andHolshouser, W.L., “Effect of Oleophobic Films on Metal Fatigue,”J. Res. Nat. Bureau of Stand.,64C (2),147–150 (April–June 1960).

Wadsworth, N.J., “The Effect of Environment on Metal Fatigue,” Proc. Symp. on Internal Stresses and Fatigue in Metals, 1958, from International Stresses and Fatigue in Metals, Elsevier Publishing Co., 382–391 (1959).

Leybold, H.A., Hardrath, H.F. and Moore, R.L., “An Investigation of the Effects of Atmospheric Corrosion on the Fatigue Life of Aluminum Alloys,” NACA TN-4331 (1958).

Bennett, J.A., Holshouser, W.L. and Utech, H.P., “The Importance of Environment in Fatigue Failure of Metals,” Fatigue of Aircraft Structures, Proc. Symp. on Fatigue of Aircraft Structures, May 1961, Pergamon Press, Macmillan Co., 1–18 (1963).

Hartman, A., “On the Effect of Oxygen and Water Vapor on the Propagation of Fatigue Cracks in 2024-T3 Alclad Sheet,”Int. J. Frac. Mech.,1,167–188 (Sept. 1965).

Dunsby, J.A. andWiebe, W., “Effect of Atmospheric Humidity on Aircraft Structural Alloy Fatigue Life,”Mat. Res. and Stand.,9,15–22 (Feb. 1969).

Womack, E.F., “Effect of Relative Humidity on Fatigue of Anodized 2024-T351 Aluminum in Completely Reversed Torsion,” MS Thesis, Virginia Polytechnic Institute and State University (Dec. 1973).

Waterhouse, R.B., Fretting Corrosion, Pergamon Press (1972).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wilson, J.H., Mabie, H.H. & Gogoll, T.H. The effect of relative humidity and coatings on the torsional fatigue of aluminum. Experimental Mechanics 22, 392–397 (1982). https://doi.org/10.1007/BF02325406

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02325406