Abstract

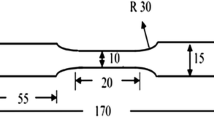

The article deals with the fatigue life of plates with hole made of aluminum alloy. Specifically, the combined effect of cold working expansion and ring indentation on improved fatigue life performance was investigated. Multiple fatigue tests were performed to determine the cycles to failure and the corresponding Wöhler diagram. Experimental results were compared with those of nontreated specimens. The conclusion was that cold working expansion and indentation create a delay on crack formation and fatigue failure.

Similar content being viewed by others

References

Kenderian, S., Djordjevic, B.B., Cerniglia, D., and Garcia, G., Dynamic Railroad Inspection Using the Laser-Air Hybrid Ultrasonic Technique, Insight 48: 336–341 (2006).

Ozdemir, A.T., and Edwards, L., Measurements of the Three-Dimensional Residual Stress Distribution Around Split-Sleeve Cold-Expanded Holes, The Journal of Strain Analysis 31: 413–421 (1996).

Nigrelli, V., and Pasta, S., Finite-Element Simulation of Residual Stress Induced by Split-Sleeve Cold-Expansion Process of Holes, Journal of Materials Processing Technology 205: 290–296 (2008).

Zhang, X., and Wang, Z., Fatigue Life Improvement in Fatigue-Aged Fastener Holes Using the Cold Expansion Technique, International Journal of Fatigue 25: 1249–1257 (2003).

Kang, J., Johnson, W.S., and Clark, D.A., Three-Dimensional Finite Element Analysis of the Cold Expansion of Fastener Holes in Two Aluminium Alloys, Transactions of the ASME Journal of Engineering Materials and Technology 124: 140–145 (2002).

O’Brien, E.W., Beneficial Residual Stress from the Cold Expansion of Large Holes in Thick Light Alloy Plate, Journal of Strain Analysis for Engineering Design 35: 261–276 (2000).

Pasta, S., Fatigue Crack Propagation From a Cold-Worked Hole, Engineering Fracture Mechanics 74: 1525–1538 (2007).

Wanlin, G., Elastic–Plastic Analysis of an Infinite Sheet With a Cold-Worked Hole, Engineering Fracture Mechanics 46: 465–472 (1993).

Zhang, Y., Fitzpatrick, M.E., and Edwards, L., Analysis of the Residual Stress around a Cold-expanded Fastener Hole in a Finite Plate Strain 41:59–70 (2005).

Lim, W.K., Song, J.H., and Sankar, B.V., Effect of Ring Indentation on Fatigue Crack Growth in an Aluminum Plate, International Journal of Fatigue 25: 1271–1277 (2003).

D’Acquisto, L., and Pasta, S., On the Measurement and Prediction of the Out-of-Plane Displacement Surrounding Cold-Expanded Holes, Experimental Mechanics 51: 11–22 (2011).

Nigrelli, V., Borruso, V., and Virzì Mariotti, G., “Improvements of Fatigue Life in Drilling Structures by Both Cold Expansion and Indentation,” ICEM12 – 12th International Conference on Experimental Mechanics, Politecnico di Bari, Italy; 29 August - 2 September, (2004).

Lim, W.K., Yoo, J.S., and Choi, S.Y., The Effect of Concurrent Cold-Expansion and Ring-Indentation on the Growth of Fatigue Cracks Emanating From Circular Holes, Engineering Fracture Mechanics 59: 643–653 (1998).

Hsu, Y.C., and Forman, R.G., Elastic–Plastic Analysis of an Infinite Sheet Having a Circular Hole Under Pressure, Journal of Applied Mechanics 42: 347–352 (1975).

Nadai, A., Theory of the Expanding of Boiler and Condenser Tube Joints Through Rolling, Transactions of the ASME 65: 865–880 (1943).

Rich D. L., Impellizzeri L. F., Fatigue Analysis of Cold-Worked and Interference Fit Fastener Holes. Cyclic Stress–Strain and plastic Deformation Aspects of Fatigue Crack Growth, ASTM STP 637 – American Society for Testing and Materials, Philadelphia, 1977, 153–175.

Ball, D.L., Elastic–Plastic Stress Analysis of Cold Expanded Fastener Holes, Fatigue and Fracture of Engineering Materials and Structures 18: 47–63 (1995).

Budynas R.G., Nisbett K.J., Shigley’s Mechanical Engineering Design, McGraw-Hill, New York, 2010.

Pyttel, B., Schwerdt, D., and Berger, C., Very High Cycle Fatigue – Is There a Fatigue Limit?, International Journal of Fatigue 33: 49–58 (2011).

Budiansky, B., A Reassessment of Deformation Theories of Plasticity, Journal of Applied Mechanics 81: 259–264 (1959).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marannano, G., Virzì Mariotti, G., D’Acquisto, L. et al. Effect of cold working and ring indentation on fatigue life of aluminum alloy specimens. Exp Tech 39, 19–27 (2015). https://doi.org/10.1111/ext.12018

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1111/ext.12018