Abstract

Conventional organic-epoxy adhesives outgas when exposed to ultra-high vacuum and, as operating temperatures are increased, they begin to exhibit plastic behavior causing hysteresis and zero instability in the transducer. The use of an inorganic glass as the bonding material has resulted in a significant advance in transducer-fabrication technology for the following reasons:

-

1.

The outgassing of transducers in high-vacuum applications is minimized.

-

2.

Mechanical properties of the transducer such as hysteresis and repeatability are improved.

-

3.

The electrical isolation of the strain gages from the metallic elements of the transducer is increased at high temperatures over that provided by epoxy. Also, the glass bond can survive and operate in severe radiation environments, wherein the epoxy adhesive will suffer either temporary or permanent loss of its dielectric strength.

-

4.

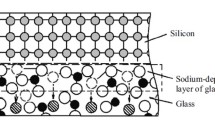

Glass-bonding techniques are particularly useful for the extension of the temperature range of operation of silicon-strain-gage transducers.

Nispan C and 440-C stainless-steel substrates were successfully used with glass-bonded silicon strain gages to fabricate transducers for evaluation.

Similar content being viewed by others

Abbreviations

- b :

-

width, in

- E :

-

modulus of elasticity, psi

- E o :

-

applied voltage, v

- e o :

-

output voltage, v

- GF :

-

gage factor

- h :

-

thickness of beam, in.

- l :

-

free length of beam, in.

- R :

-

unbonded-strain-gage resistance, ohm

- †R :

-

change in resistance, ohm

- T :

-

room temperature, or a reference temperature, °F

- T cv :

-

temperature at which the adhesive set up as a solid during the curing process, °F

- W :

-

load applied to end of beam, lb

- X :

-

distance measured from clamped end, in.

- \(\frac{1}{{(GF)}}\frac{{d(GF)}}{{dT}}\) :

-

the unbonded temperature coefficient of gage factor, percent/°F

- \(\frac{1}{R}\frac{{dR}}{{dT}}\) :

-

the temperature coefficient of resistance of the bonded gage, percent/°F

- α m :

-

coefficient of thermal expansion of the metal to which the gage is bonded, in./in./°F

- α si :

-

coefficient of thermal expansion of silicon, in./in./°F

- β:

-

correction term relating bonded and unbonded temperature characteristics, percent/°F

- ε:

-

strain, in./in.

Author information

Authors and Affiliations

Additional information

W. A. Leasure, Jr. was Aerospace Engineer, National Aeronautics and Space Administration, Greenbelt, Md. 20771 at time this paper was prepared

Rights and permissions

About this article

Cite this article

Leasure, W.A., Woodruff, N. & Gravel, C. Glass-bonding techniques for semiconductor strain gages. Experimental Mechanics 11, 235–240 (1971). https://doi.org/10.1007/BF02324223

Issue Date:

DOI: https://doi.org/10.1007/BF02324223