Abstract

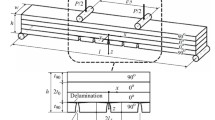

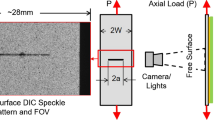

Birefringent coatings have been employed to study the effectiveness of an adhesively bonded repair of a center-cracked tension panel. The repair was one sided, with photoelastic coatings applied to the opposite side. Photoelastic coatings were also applied over the patch. Analysis methods are presented to permit the stress intensity factor to be determined from the isochromatic fringe patterns recorded from both continuous andX- andY-edged coatings. The results showed that the one-sided adhesively bonded patch reduced the stress intensity factor; however, the repair did not markedly change the character of stress distributions. Fringe loops formed near the crack tips for both the cracked and repaired tension panels. The primary difference was in the size of the loops. The reduction inK I due to repair was smaller than anticipated, but even small improvements in ΔK I markedly enhance the life of a repaired panel. The Paris power law is used to show the relation between the reduction in ΔK I and the improvement in the crack growth rateda/dN. Fringe patterns from the birefringent coatings applied to the patch provided a means not only to investigate the stresses in the patch but also to detect the initiation of the local debonding of the adhesive in the neighborhood of the crack. The birefringent coating on the patch is an approach for producing an optically “smart” repair.

Similar content being viewed by others

References

Baker, A.A. andJones, R., Bonded Repair of Aircraft Structures, Martinus Nijhoff, Boston (1988).

Fredell, R., “Damage Tolerant Repair Techniques for Pressurized Aircraft Fuselages,”Ph.D. diss., Faculty of Aerospace Engineering, Delft University of Technology, the Netherlands (June 1994).Also published as Wright Laboratory Technical Report 94-3134 (June 1994).

Zandman, F., Redner, S., andDally, J.W., Photoelastic Coatings, Iowa State University Press, Ames (1977).

Dally, J.W. andRiley, W.F., Experimental Stress Analysis, 3rd ed., McGraw-Hill, New York (1991).

Irwin, G.R., “Discussion of Paper by Wells, A. and D. Post: The Dynamic Stress Distribution Surrounding a Running Crack—A Photoelastic Analysis,”Proc. SESA,16 (1),93–96 (1958).

Bradley, W.B. andKobayashi, A.S., “An Investigation of Propagating Cracks by Dynamic Photoelasticity,” EXPERIMENTAL MECHANICS,10,106–113 (1970).

Smith, D.G. andSmith, C.W., “Photoelastic Determination of Mixed-mode Stress Intensity Factors,”Eng. Fract. Mech.,4 (2),357–366 (1972).

Dally, J.W., “Developments in Photoelastic Analysis of Dynamic Fracture,”Optical Methods in Mechanics of Solids, ed. A. Lagarde, Sijthoff and Noordhoff, Roekville, MD, 359–394 (1979).

Fredell, R., “Damage Tolerant Repair Techniques for Pressurized Aircraft Fuselages,” Wright Laboratory Technical Report 94-3134 (June 1994).

Paris, P.C., “Fatigue—An Interdisciplinary Approach,”Proc. 10th Sagamore Conference, Syracuse University Press, Syracuse, NY, 107 (1964).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hastie, R.L., Fredell, R. & Dally, J.W. A photoelastic study of crack repair. Experimental Mechanics 38, 29–36 (1998). https://doi.org/10.1007/BF02321264

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02321264