Abstract

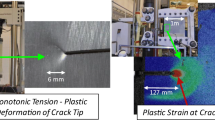

Composite patch repairs are an alternative to weld repair methods to arrest crack growth in metal plates. While these repairs have been effective, it has been difficult to use basic linear elastic fracture mechanics (LEFM) theories and design methods based on LEFM to predict the efficacy of patch repairs because the repaired plate exhibits bending and significant crack tip plasticity. In this investigation, we have studied the effect that one-sided low modulus composite patch repairs have on the development of crack tip plasticity on the free surface and through the thickness using large strain area and volume, total axial stress balance, and the free surface J-integral. Digital Image Correlation (DIC) and three-dimensional finite element analysis with first order elements were used to understand the evolution of crack tip plasticity and strain energy release rate to develop a simplified prediction method identifying a characteristic crack opening displacement prior to crack tip behavior of a one-sided composite patch repaired Center-Cracked Tension (CCT) specimen transitioning from Small Scale Yielding (SSY) to Large Scale Yielding (LSY), and eventually the re-initiation of crack growth. This method was then validated by comparing the predicted characteristic transition load to observed ultimate patched CCT specimen load capacity. Results correlated well with predictions when the composite patch was perfectly bonded to the aluminum and predicted characteristic transition loads more than 90\(\%\) greater than LEFM based failure predictions and 25\(\%\) lower than observed ultimate failure loads, demonstrating the potential to use this method for patch repair optimization.

Similar content being viewed by others

References

ABAQUS (2018) ABAQUS documentation. Dassault Systémes, Providence, RI, USA

Anderson TL (1995) Fracture mechanics fundamentals and applications, 2nd edn. CRC Press LLC, Boca Raton

Baker AA, Rose LR, Jones R (2002) Advances in the bonded composite repair of metallic aircraft structures, vol 1. Elsevier, Amsterdam

Becker TH, Mostafavi M, Tait RB, Marrow TJ (2012) An approach to calculate the J-integral by digital image correlation displacement field measurement. Fatigue Fract Eng Mater Struct 35:971–984

Besel M, Breitbarth E (2016) Advanced analysis of crack tip plastic zone under cyclic loading. Int J Fatigue 93:92–108

Bruck HA (1989) Analysis of 3-D effects near the crack tip on rice’s 2-D J-integral using digital image correlation and smoothing techniques. University of South Carolina, Department of Mechanical Engineering, Columbia

Correlated Solutions Inc. (2018) Vic-2D v6 reference manual. Correlated Solutions Inc., Irmo, SC 29063 https://www.correlatedsolutions.com

Dadkaha MS, Kobayashi AS (1990) Further studies on the HRR field of a moving crack, an experimental analysis. Int J Plast 6:635–650

Duong CN (2009) Design and validation of composite patch repairs to cracked metallic structures. Compos Part A 40:1320–1330

Fernandez-Zuniga D, Kalthoff JF, Fernandez-Canteli A, Grasa J, Doblare M (2004) Three dimensional finite element calculations of crack tip plastic zones and KIC specimen size requirements. In: Conference on European Conference on Fracture. Stockholm: Engineering Structural Integrity Society, Sweden

Hamam R, Hild F, Roux S (2007) Stress intensity factor gauging by digital image correlation: application in cyclic fatigue. Strain 43:181–192

Hart DC (2016) Aluminum sensitization and application of laminated composite patch repairs. In: Proceedings of the society for experimental mechanics XIII international congress and exposition on experimental applied mechanics, experimental dynamic behavior: integrating experimental mechanics. Orlando, FL

Hart DC, Bruck HA (2018) Low modulus composite patched aluminum center crack tension specimen DIC surface displacements compared with predictions. In: Society for experimental mechanics annual conference and exposition on experimental applied mechanics. Greenville, SC

Hart DC, Bruck HA (2020) Effects of plasticity on patched and unpatched center crack tension specimens. Exp Mech 60:345–357. https://doi.org/10.1007/s11340-019-00560-w

Hart DC, Udinski EP, Noland JM (2016) CG task force composite patch material testing. West Bethesda, MD: NSWCCD-65-TR-2015/15, Naval Surface Warfare Center Carderock Division

Hickey WF (2011) An investigation into the failure of aluminum alloys. Masters Thesis, University of Texas at Austin, Material Science and Engineering, Austin, TX

Hutchinson JW (1968) Singular behaviour at the end of a tensile crack in a hardening material. J Mech Phys Solids 16:13–31

Naboulsi S, Mall S (1997) Characterization of fatigue crack growth in aluminum panels with a bonded composite patch. Compos Struct 37(3):321–334

Nahshon K, Hoffman WA, Ullagaddi CB (2014) Characterization of structural scale ductile fracture of aluminum panels using digital image correlation. In: Proceedings of the 214 annual conference on experimental and applied mechanics

Noland JM, Hart DC, Udinski EP, Sielski RA (2013) Initiatives in bonded ship structural repairs. ASNE fleet maintenance and modernization symposium. American Society of Naval Engineers, San Diego

Ozturk F, Totos S, Kilic S (2008) Evaluation of tensile properties of 5052 type aluminum-magnesium alloy at warm temperatures. Arch Mater Sci Eng 34(2):95–98

Rice JR, Rosengren GF (1968) Plane strain deformation near a crack tip in a power-law hardening material. J Mech Phys Solids 16:1–12

Sutton MA, Turner JL, Chao YJ, Bruck HA, Chae TL (1992) Experimental investigations of three dimensional effects near a crack tip using computer vision. Int J Fract 53:201–228

Wang CH, Rose LR (1999) A crack bridging model for bonded plates subjected to tension and bending. Int J Solids Struct 36:1985–2014

Yoneyama S, Arikawa S, Kusayanagi S, Hazumi K (2014) Evaluating J-integral from displacement fields measured by digital image correlation. Strain 50:147–160

Acknowledgements

The described work was performed by the Naval Surface Warfare Center Carderock Division’s Platform Integrity Department, and the Department of Mechanical Engineering at the University of Maryland, College Park. Financial and technical support was provided by an U.S Office of Naval Research In-house Laboratory Independent Research (ILIR) program element 97X4930N under Dr. Jack Price, and a Grant provided to UMD by program officer Dr. Paul Hess of the Office of Naval Research Code 331 under Grant Number N000141612351. Opinions expressed are those of the authors and do not necessarily reflect opinions of the sponsors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hart, D.C., Bruck, H.A. Predicting failure of cracked aluminum plates with one-sided composite patch. Int J Fract 227, 205–218 (2021). https://doi.org/10.1007/s10704-020-00509-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00509-4