Abstract

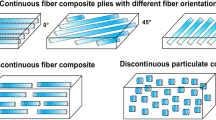

Fiber-reinforced flexible composites are extensively used for different kinds of applications, for example, tubes, drive belts, tires, and coated fabrics. Typical for these materials are matrix materials allowing large strain deformation and reinforcement structures allowing bending. Apart from the tensile strength and limited bending stiffness, damage resistance and ductile-brittle transition characteristics are discussed. The tensile strength usually follows the rule of mixture. The mode of fracture and damage resistance, however, strongly depend on penetration of the matrix into the fiber bundles, textile structure, and internal friction. Models for the work of fracture and the ductile-to-brittle fracture transition are discussed.

Similar content being viewed by others

References

P. Gredinger, Fracture Modelling and Analysis of Processes in Coated Fabrics, M. Sci. Thesis, Lund University, Lund (1997).

C.-H. Andersson and T. Dartman, Analysis of Tensile Stiffness, Damage Resistance and Strength of Flexible Textile Composites, TEFO TTT-Internal Report, Göteborg (1990).

C.-H. Andersson, Skadetålighet och rivhållfasthet hos belagda dukvaror 1-grundläggande mekanismer, TEFO TTT-Internal Report [in Swedish], Göteborg (1996).

Bin Ahmad and M. F. Ashby, “Failure-mechanism maps for engineering polymers,” J. Mater. Sci.,23, 2037–2050 (1988).

Tsu-Wei Chou, “Review, flexible composites,” J. Mater. Sci.,24, 761–783 (1989).

V. K. Hewinson, “A study of coating-to-fabric adhesion and the tearing of coated nylon fabrics,” J. Text. Inst.,53, 766–782 (1962).

S. Kawabata, “Measurements of the transverse mechanical properties of high-performance fibers,” J. Text. Inst.,81, 432–447 (1990).

Frank K. Ko, “Preform fiber architecture for ceramic-matrix composites,” Ceram. Bull.,68, No. 2 (1989).

John E. Masters, “Basic failure modes of continuous fiber composites,” in: Eng. Materials Handbook, Composites. Vol. 1, ASM Int., Metals Park, Ohio (1987), pp. 781–785.

S. Backer, “Fibrous materials,” in: Frank A. McClintock, Ali S. Argon (eds.), Mechanical Behaviour of Materials, Addison-Wesley Publ. Reading, Mass. (1966), pp. 675–705.

N. J. Abbott, T. E. Lannerfield, L. Barrish, and R. J. Brysson, “A study of tearing in coated cotton fabrics. Pt. I: The influence of fabric construction,” in: Coated Fabrics Technology, Technomic Publishing Inc., Westport (1973), pp. 1–14.

E. D. Frederick and M. C. Henry, “A study of tearing in coated cotton fabrics. Pt. II: The influence of coating techniques,” in: Coated Fabrics Technology, Technomic Publishing Inc., Westport (1973), pp. 15–62.

N. J. Abbott, T. E. Lannerfield, L. Barrish, and R. J. Brysson, “A study of tearing in coated cotton fabrics, Pt. III: The influence of coating application techniques,” in: Coated Fabrics Technology, Technomic Publishing Inc., Westport (1973), pp. 89–108.

N. J. Abbott and J. Skelton, “Crack propagation in woven fabrics,” in: Coated Fabrics Technology, Technomic Publishing Inc., Westport (1973), pp. 121–139.

T. C. Kennedy, “Application of composite fracture models to coated fabrics,” J. Coat. Fab.,24, 129–136 (1994).

T. Dartman and R. Shishoo, “Studies of adhesion mechanisms between PVC coating and different textile substrates,” J. Coat. Fab.,22, 317–334 (1993).

D. Hull, An Introduction to Composite Materials, Cambridge University Press, Cambridge (1981).

L. R. G. Treloar and G. Riding, “A theory of the stress-strain properties of continuous-filament yarns,” J. Text. Inst.,54 T156-T170 (1963).

J. W. S. Hearle, “On the theory of mechanism of twisted yarns,” J. Text. Inst.,60, 95–101 (1969).

J. W. S. Hearle, H. M. A. E. El-Behery, and V. M. Thakur, “The mechanics of twisted yarns: theoretical developments,” J. Text. Inst.,52, T197-T220 (1961).

J. W. S. Hearle, “The mechanics of twisted yarns: the influence of transverse forces on tensile behaviour,” J. Text. Inst.,49, T389-T408 (1958).

E. R. Kaswell, Wellington Sears Handbook of Industrial Textiles, Wellington Sears Company, Inc., New York (1963).

T.-W. Chou and F. K. Ko, Textile Structural Composites. Vol. 3, Compos. Mater. Series, Elsevier Inc., Amsterdam (1989).

X. Tao, “Mechanical properties of a migrating fiber,” Text. Res. J.,66, 754–762 (1996).

Peter Schwarz, Structural Design, Cornell Univ., Ithaca, New York (1996).

B. von Falkai, Synthesefasern-Grundlagen, Technologie, Verarbeitung und Anwendung, Verlag Chemie Gmbh., Weinheim (1981).

H. H. Yang, Kevlar Aramide Fibre, John Wiley & Sons, Ltd., (1993).

W. E. Morton and J. W. S. Hearle, Physical Properties of Textile Fibres, Butterworth & Co. Ltd., The Textile Institute, Manchester (1962).

R. J. Young and W.-E. Yeh, “Chain stretching in a poly(ethylene terephthalate) fiber,” Polymer,35, No. 18, 3844–3847 (1994).

M. C. Andrews, D. Lu, and R. J. Young, “Compressive properties of aramide fibers,” Polymer,38, No. 10, 2379–2388 (1997).

T. Czinganzy and J. Karger-Kocsis, “Determination of the damage zone size in textile reinforced polypropylene composites by locating the acoustic emission,” Polymers Polym. Compos.,1, No. 5, 329–339 (1993).

K. Eng, “Gewebe/Gewirk-vergleich, D.O.S.-Structuren: sehr gut.,” Kettenwirk-praxis, No. 4, 43–47 (1996).

Author information

Authors and Affiliations

Additional information

Published in Mekhanika Kompozitnykh Materialov, Vol. 34, No. 6, pp. 747–760, November–December, 1998.

Rights and permissions

About this article

Cite this article

Andersson, CH., Dartman, T., Gredinger, P. et al. Flexible composites, strength, deformation, and fracture processes. 1. Reinforcement structures and tensile strength. Mech Compos Mater 34, 525–536 (1998). https://doi.org/10.1007/BF02254661

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02254661