Abstract

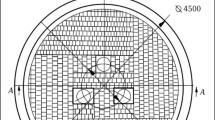

Specimens taken from the inlets of the electrodes of an arc furnace and the near zone after service are investigated. It is established that the porous structure of the specimens caused by mullitization at high temperatures intensifies the effect of slag on the refractory material. The process leads to the formation of hercynite, ringwoodite, and spinel. The formation of hercynite reduces the service life of linings.

Similar content being viewed by others

References

D. F. Marshall, “The role of arc furnace in steel making,” in:The Refractories (1977), p. 16.

J. N. Chesters,Refractories for Iron and Steel Making (1974), p. 141.

H. N. Umredkar et al., “Maintenance and repairs of electric arc furnaces. Workshop on application eng. for refractories,”IRMA (1989), p. 34.

K. K. Singh, “Refractories for ladles and hot metals mixtures,”IRMA Jr.,XXIII(3) (1990).

R. Jhunjhunwala et al., “Refractories for UHP electric furnaces,” in:Inter. Conf. on Role of Mini Steel Plants, New Technologies and Challenges, pp. 16–41.

J. H. Chesters,Refractories, Production and Properties (1973), p. 175.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 8, pp. 27–29, August, 1995.

Rights and permissions

About this article

Cite this article

Hegde, S.B., Chaturvedi, S. Service of high-alumina refractories in ARC furnaces. Refractories 36, 262–264 (1995). https://doi.org/10.1007/BF02227399

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02227399