Abstract

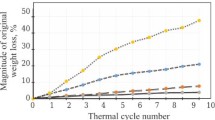

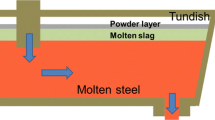

The decarburization kinetics of alumina-periclase-carbon refractories is considered. Such refractories are widely used at steel plants in the working layer of casting-ladle linings. The decarburization depth depends on the temperature and time and also on the composition of the atmosphere. The working life of resin-bound alumina-periclase-carbon refractories depends not only on its porosity but also on the presence of graphite flakes and carbon particles in the surface layer, since they reduce the wettability of the refractory surface by metal and slag and also reduce the uniformity of the refractory’s thermophysical and mechanical properties over the cross section. Difference in composition of the decarburized and unmodified layers of the refractory may lead to cracks and chips due to the thermal stresses on heating and cooling of the lining. The influence of the temperature and the atmospheric composition on the porosity of alumina-periclasecarbon ladle refractories is studied. The results show that high temperatures increase the porosity of the material. Heat treatment in an oxygen-free atmosphere eliminates decarburization, but there is little change in the water absorption and porosity of the refractories.

Similar content being viewed by others

References

Krivandin, V.A. and Egorov, A.V., Teplovaya rabota i konstruktsii pechei chernoi metallurgii (Thermal Operation and Design of Furnaces in Ferrous Metallurgy), Moscow: Metallurgiya, 1989.

Margishvili, A.P., Mozhzherin, A.V., Musevich, V.A., and Duka, A.P., Nov. Ogneup., 2011, no. 11, pp. 15–21.

Visloguzova, E.A., Kashcheev, I.D., Serova, L.V., and Khoroshikh, M.A., Nov. Ogneup., 2010, no. 1, pp. 7–10.

Temlyantsev, M.V. and Matveev, M.V., Metallurg, 2010, no. 8, pp. 60–62.

Temlyantsev, M.V. and Matveev, M.V., Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2010, no. 10, pp. 38–40.

Temlyantsev, M.V., Matveev, M.V., and Temlyantseva, E.N., Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2011, no. 10, pp. 32–36.

Temlyantsev, M.V., Matveev, M.V., Kostyuchenko, K.E., and Temlyantseva, E.N., Vestn. Gorno-Metall. Sekts. RAEN, Otd. Metallurg., 2012, issue 29, pp. 58–62.

Gosh, N.K., Kuzhur, M.K., Roichoudzhuri, P.K., et al., Nov. Ogneup., 2011, no. 9, pp. 5–8.

Ivashchenko, L.V., Romanovskii, L.B., Shevchenko, G.I., et al., Ogneupory, 1986, no. 11, pp. 8–12.

Kasheev, I.D., Sizov, V.I., and Panin, O.A., Ogneupory, 1989, no. 8, pp. 7–9.

Improving the oxidation resistance of high-carbon concrete by means of an antioxidant mixture, OAO Chermetinformatsiya: Nov. Chern. Metall. Rub., 2011, no. 1, pp. 88–91.

Simonov, K.V., Koptelov, V.N., Burdina, G.V., and Sakk, V.I., Ogneupory, 1989, no. 10, pp. 32–34.

Da Silveira, W., Falk, G., and Clausen, R., Ogneup. Tekhn. Keram., 2010, no. 10, pp. 32–41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.V. Protopopov, M.V. Temlyantsev, E.M. Zapol’skaya, K.E. Maksakova, V.A. Degtyar’, 2014, published in “Izvestiya VUZ. Chernaya Metallurgiya,” 2014, No. 12, pp. 24–28.

About this article

Cite this article

Protopopov, E.V., Temlyantsev, M.V., Zapol’skaya, E.M. et al. High-temperature decarburization of alumina-periclase-carbon ladle refractories. Steel Transl. 44, 879–882 (2014). https://doi.org/10.3103/S0967091214120158

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091214120158