Abstract

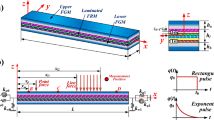

A test stand designed for experimental study of the kinetics of fatigue fracture is examined as a nonlinear dynamic system with variable parameters. A analytical model is constructed to describe the loading of a specimen having a fatigue crack and subjected to symmetric cyclic loading. The equation of the loading process is obtained and, for fixed parameter values, expanded into a Fourier series. It is shown that the process of crack growth is characterized by the appearance of a constant component and harmonics that are multiples of the exciting frequency in the output signal. An information parameter is chosen that determines the change in compliance over time during the growth of the fatigue crack in the specimen. Algorithms are developed and instrument configurations found to determine the law governing the change in compliance. An example of the use of the instrument to record crack nucleation and growth is examined.

Similar content being viewed by others

References

V. T. Troshchenko, V. V. Pokrovskii, and A. V. Prokopenko, Fracture Toughness of Metals under Cyclic Loading [in Russian], Naukova Dumka, Kiev (1987).

O. N. Romaniv, S. Ya. Yarema, G. N. Nikiforchin, et al., Fatigue and Cyclic Fracture Toughness of Structural Materials [in Russian], Vol. 4 of Fracture Mechanics and the Strength of Materials (editor: V. V. Panasyuk), Naukova Dumka, Kiev (1988–1990).

J. F. Knott, Principles of Fracture Mechanics [Russian translation], Metallurgiya (1978).

T. A. Lebedev, T. K. Marinets, and A. I. Efremov, “Study of the fatigue strength of metals by recording fatigue curves,” in: Fatigue Strength of Metals: Materials of the Second Conference on Metal Fatigue, Izd. AN SSSR, Moscow (1962), pp. 141–146.

V. P. Golub, A. D. Pogrebnyak, and A. V. Zheldubovskii, Inventor's Certificate No. 1057805 USSR, MKI N 01 No. 3/32, “Method of determining fatigue damage to materials,” Otkrytiya, Izobreteniya, No. 44, 157 (1983).

V. P. Golub, “Method of experimentally studying the kinetics of fatigue fracture,” Zavod. Lab., No. 4, 67–69 (1986).

S. I. Kishkina, Fracture Toughness of Aluminum Alloys [in Russian], Metallurgiya, Moscow (1981).

M. E. Garf (editor), Machines and Instruments for Fatigue Tests [in Russian], Naukova Dumka, Kiev (1970).

V. P. Butseroga and O. B. Balakovskii, “Determination of the transfer factors of loaded elements in machines with kinematic excitation,” Prikl. Mekh.,19, No. 5, 113–118 (1983).

V. P. Butseroga, “Automation of machines for fatigue tests with cyclic excitation,” Probl. Prochn., No. 4, 110–114 (1983).

S. V. Serensen, M. E. Garf, and V. A. Kuz'menko, Dynamics of Machines for Fatigue Tests [in Russian], Mashinostroenie, Moscow (1967).

G. Korn and T. Korn, Handbook of Mathematics for Scientists and Engineers [Russian translation], Nauka, Moscow (1968).

V. P. Golub, V. P. Butseroga, and A. D. Pogrebnyak, “Study of the kinetics of fatigue cracks by the method of differential compliance,” Prikl. Mekh.,31, No. 12, 66–73 (1995).

Author information

Authors and Affiliations

Additional information

Deceased.

Translated from Problemy Prochnosti, No. 2, pp. 110–119, February, 1996.

Rights and permissions

About this article

Cite this article

Butseroga, V.P. Unit for experimental study of fatigue-crack growth. Strength Mater 28, 158–165 (1996). https://doi.org/10.1007/BF02215843

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02215843