Abstract

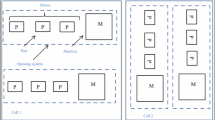

The problem of interest is to partition a collection of machines into production cells so that a given set of part-manufacturing requirements may be carried out optimally. In the present case transitions of parts between different cells is the only measure of machine partition goodness. The present formulation and approximate solution of this optimization problem is best described as one of successive approximations or as a one-at-a-time method. An initial cellular structure is taken and an easy part assignment optimization routine executed. With the part assignment fixed, a heuristic is employed to find an improved cell structure. These bipartite iterations continue until a convergence criterion is satisfied. Several small computer examples are provided and the straightforward requirements for large problem adaptation.

Similar content being viewed by others

References

J.L. Burbidge,The Introduction of Group Technology (Heinemann, London, 1975).

H. Everett, Generalized Lagrange multiplier method for solving problems of optimum allocation of resource, Ops. Res. 11 (1963) 399–417.

G.U. Fazakerly, A research report on the human aspects of group technology and cellular manufacture, Prod. Res. 14, 1 (1976) 135–144.

J. King and V. Nakornchai, Machine-component group formation in group technology: a review and extension, International Journal Prod. Res. 20, 2 (1982) 117–133.

J. McAuley, Machine grouping for efficient production, The Prod. Engr. (Feb. 1972) 53–57.

R. Rajagopalan and J. Batra, Design of cellular production systems, International Journal of Prod. Res. 13 (1975) 567.

L. Schrage,User's Manual for LINDO (Scientific Press, Palo Alto, Calif., 1981).

R.H. Sinha and R.H. Hollier, A review of production control problems in cellular manufacturing, International Journal of Prod. Res. 22, 5 (1984) 773–789.

L. Stanfel, Machine clustering for economic production, Engr. Costs and Prod. Econ. 9 (1985) 73–81.

L. Stanfel, Partitioning problems in cellular manufacturing, A.P.I.I. 19 (1985) 523–536.

K. Stecke, Formulation and solution of nonlinear integer production planning problems for flexible manufacturing systems, Management Science 29, 3 (1983) 273–288.

P. Waghodekar and S. Sahu, Machine-component cell formation in group technology: MACE, international Journal of Prod. Res. 22, 6 (1984) 937–948.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stanfel, L.E. A successive approximations method for a cellular manufacturing problem. Ann Oper Res 17, 13–30 (1989). https://doi.org/10.1007/BF02096596

Issue Date:

DOI: https://doi.org/10.1007/BF02096596