Abstract

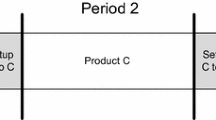

This paper deals with the dynamic behaviour of an FMS when parts are released periodically. The minimal release period is induced by the most critical machine or fixture pallet type. Moreover, with a fixed period, the limited number of available pallets induces a maximal flow time for every part type. Thus, the objective of this paper is to determine a part release strategy and an activity schedule on every machine which allows to control every part flow time for steady state. An analysis method for this objective is presented in this paper. Its purpose is to obtain releasing and scheduling conditions ensuring a workshop steady state compatible with the considered constraints, especially part flow times. This method is based on the resolution of conflicts between activities processed on a common machine. This resolution uses limit times associated with each activity and it can modify these limit times. These modifications in turn can induce modifications for other activity limit times due to part routing, steady-state periodicity, and part flow time constraints. Thus, an iterative procedure has been defined. It refines steady-state feasibility conditions through limit times and sequencing conditions of activities processed on a common machine. The method is illustrated with two examples.

Similar content being viewed by others

References

K.R. Baker,Introduction to Sequencing and Scheduling (Wiley, New York, 1974).

M. Berrada and K. Stecke, A branch and bound algorithm for FMS machine loading,Proc. 1st ORSA/TIMS Conf. on Flexible Manufacturing Systems, Ann Arbor, USA (1984).

R. Conway, M. Maxwell, L. Miller,Theory of Scheduling (Addison Wesley, 1967).

J. Erschler, F. Roubellat and J.P. Vernhes, Finding some essential characteristics of the feasible solutions for a scheduling problem, Oper. Res. 24, 4(1976)774.

J. Erschler, G. Fontan and F. Roubellat, Potentiels sur un graphe non conjonctif et analyse d'un problème d'ordonnancement à moyens limités, RAIRO, série verte, vol. 13, no. 4 (1979).

J. Erschler, F. Roubellat and J.P. Vernhes, Characterizing the set of feasible sequences forn jobs to be carried out on a single machine, Euro. J. Oper. Res. 4, 3(1980)189.

J. Erschler, D. Levèque and F. Roubellat, Periodic loading of flexible manufacturing systems,Advances in Production Management Systems (Bordeaux, 1982).

K.L. Hitz, Scheduling of flexible flow shops, Tech. Rep. 879, L.I.D.S. Massachusetts Institute of Technology (March, 1979).

K.L. Hitz, Scheduling of flexible flow shops II, Tech. Rep. 1049, L.I.D.S. Massachusetts Institute of Technology (October 1980).

D. Levèque, Lancement périodique de produits dans un atelier flexible, Thèse de Docteur-Ingénieur, Toulouse (1982).

K. Stecke, Formulation and solution of nonlinear integer production planning problems for FMS, Management Science 29, 3(1983)273.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Erschler, J., Roubellat, F. & Thuriot, C. Steady state scheduling of a flexible manufacturing system with periodic releasing and flow time constraints. Ann Oper Res 3, 333–353 (1985). https://doi.org/10.1007/BF02023748

Issue Date:

DOI: https://doi.org/10.1007/BF02023748