Contents

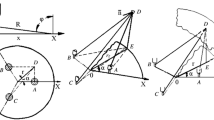

This paper deals with a general design of a linearized mathematical model of an arc furnace electric circuit. The linearized model of the asymmetrical circuit with linear loads is derived in matrix-vector notation. The model consists of sensivity function matrices of the circuit-phase currents versus arc voltages, supply voltages and equivalent phase inductances. An example of application of this model to the determination of the inductances of the circuit is given. Other possibilities of implementation of this model are discussed.

Übersicht

In dieser Arbeit wird die allgemeine Form eines linearisierten mathematischen Modells des elektrischen Kreises des Lichtbogenofens vorgestellt. Das linearisierte Modell des unsymmetrischen Kreises mit linearer Belastung wird durch Anwendung der Vektor-Matrixschreibweise erhalten. Das Modell umfaßt die Matrizen der Funktionen der Empfindlichkeiten der Ströme in jeden einzelnen Phasen betreffs der Lichtbogenspannungen, der Speisespannungen und der Phasenäquivalentsinduktivitäten. Es wird ein Beispiel der Anwendung dieses Modells für die Phaseninduktivitätenbestimmung angegeben. Es werden auch andere Anwendungsmöglichkeiten des erhaltenen Modells dargestellt.

Similar content being viewed by others

References

Hanas, B.; Modern design principles for arc furnace for steelmaking. ASEA J. 42 (1968) 103–108

Schwabe, W. E.; Robinson, C. G.: Development of large steel furnaces from 100-to 400-ton Capacity. VII. Congr. U.I.E. 1972, Rep. No. 105

Schwabe, W. E.; Robinson, C. G.: Experience with ultra-high power electric furnace operation. VI. Congr. U.I.E. 1968, Report No. 104.

Bretthauer, K.; Timm, K.: Effects of unbalance on the wear of arc furnaces and how they are measured. VII. Congr. U.I.E. 1972, Report No. 406 (in German)

Bretthauer, K.; Farschtschi, A. A.; Symmetring of a electric variables of an arc furnace. Elektrowärme Int. 34 (1976) 245–251 (in German)

Bilings, S. A.; Nicholson, H.: Temperature weighting adaptive controller for electric arc furnaces. Ironmaking Steelmaking. 4 (1977) 216–221

Wierzbicki, A.: Models and sensivity of control systems. Warsaw: WNT 1977 (in Polish)

Kalic, D.; Bogdanovic, S.; Bulajic, R.: Analysis of the three-phase non-linear electric circuit of the arc furnace for steel production. Elektrowärme Int. 40 (1982) 24–29

Wciślik, M.: An analysis of the arc furnace electric system with nonlinear load. Ph. D. Diss. Tech. Univ. of Warsaw 1981 (in Polish)

Okamura, M.; Watanabe, M.; Usui, K.; Kon, J.: UHP Arc furnace electrodes-Effects of arc and estimation of quality by use of a model arc furnace. VII. Congr. of U.I.E. 1972, Rep. No. 401

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wciślik, M. A linearized mathematical model of a three-phase arc furnace circuit. Archiv f. Elektrotechnik 68, 273–278 (1985). https://doi.org/10.1007/BF01845939

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01845939