Abstract

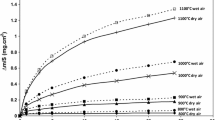

The corrosion of pure Co and Y and of a Co-15 wt.% Y alloy in H2-H2S mixtures providing a sulfur pressure of 10−8 atm. at 600–800°C and also of 10−7 atm. at 800°C was was studied to examine the effect of yttrium on the sulfidation resistance of pure cobalt. The alloy was nearly single phase, containing mostly the intermetallic compound Co17Y2 plus a small amount of cobalt solid-solution. For all conditions except for 800°C under 10−8 atm. S2, the alloy formed multilayered scales consisting of an outer region of pure cobalt sulfide, an intermediate region of a mixture of cobalt sulfide with yttrium oxysulfide and finally an innermost layer of a mixture of yttrium oxysu fide with cobalt metal. At 800°C under 10−8 atm. S2, below the dissociation pressure of cobalt sulfide, the alloy formed only a single layer composed of a mixture of metallic cobalt with yttrium oxysulfide. Pure yttrium produced only the oxysulfide Y2O2S, as a result of the large stability of this compound and of the presence of some impurities in the gas mixtures used. The corrosion kinetics were generally rather complex, but except at 800°C under 10−8 atm. S2, the addition of yttrium reduced the sulfidation rate of cobalt, even though the formation of a continuous protective external layer of a pure yttrium compound was never achieved. Finally, when the gas-phase sulfur pressure was above the dissociation of cobalt sulfide the corrosion rate of yttrium was significantly lower than that of Co-15 Y. The internal sulfidation of Y in Co-15 Y was not associated with depletion of Y in the alloy. This difusionless kind of internal attack is typical of binary A-B alloys presenting a very small solubility of the most-reactive component B in the base metal A, which restricts severely the flux of B from the alloy toward the alloy-scale interface.

Similar content being viewed by others

References

G. Y. Lai,High-Temperature Corrosion of Engineering Alloys (ASM International, Materials Park, 1990).

S. Mrowec and K. Przybylski,High Temp. Mater. Proc. 6, 1 (1984).

K. Natesan,Corrosion 41, 646 (1985).

F. Gesmundo, D. J. Young, and S. K. Roy,High Temp. Mater. Proc. 8, 149 (1989).

J. Stringer, inHigh-Temperature Oxidation and Sulfidation Processes, J. D. Embury, ed. (Pergamon Press, New York, 1990), p. 257.

F. Gesmundo, inHigh Temperature Materials for Power Engineering 1990, Vol. 1, E. Bachelet, ed. (Kluwer Academic Publishers, Dordrecht, 1990), p. 67.

B. Gleeson, D. L. Douglass, and F. Gesmundo,Oxid. Met. 31, 209 (1989).

M. F. Chen, D. L. Douglass, and F. Gesmundo,Oxid. Met. 31, 237 (1989).

R. V. Carter, D. L. Douglass, and F. Gesmundo,Oxid. Met. 31, 341 (1989).

M. F. Chen and D. L. Douglass,Oxid. Met. 32, 185 (1989).

G. Wang, R. Carter, and D. L. Douglass,Oxid. Met. 32, 273 (1989).

B. Gleeson, D. L. Douglass, and F. Gesmundo,Oxid. Met. 33, 425 (1990).

Y. Niu, F. Gesmundo, and F. Viani,Corros. Sci. 36, 423 (1994).

Y. Niu, F. Gesmundo, and F. Viani,Corros. Sci. 36, 853 (1994).

Y. Niu, F. Gesmundo, and F. Viani,Corros. Sci. 36, 883 (1994).

K. N. Strafford, G. R. Winstanley, and J. M. Harrison,Werkst. Korros. 25, 487 (1974).

C. N. R. Rao and K. P. R. Pisharody, inProgress in Solid State Chemistry, Vol. X, J. O. McCaldin and G. Somorjai, eds. (Pergamon Press, New York, 1975), p. 207.

T. B. Massalski, J. L. Murry, L. H. Bennett, and H. Baker, eds.Binary Alloy Phase Diagrams (ASM, Materials Park, 1986).

F. Gesmundo, F. Viani, and Y. Niu,Oxid. Met. 42, 409 (1994).

C. Wagner,Z. Elektrochem. 63, 772 (1959).

R. A Rapp,Corrosion 21, 382 (1965).

F. Gesmundo, F. Viani, and Y. Niu,Oxid. Met. 43, 379 (1995).

F. Gesmundo, F. Viani, and Y. Niu,Oxid. Met. 45, 51 (1996).

F. Gesmundo, F. Viani, and Y. Niu,Oxid. Met. 47, 355 (1997).

F. Gesmundo, F. Viani, Y. Niu, and D. L. Douglass,Oxid. Met. 40, 373 (1993).

F. Gesmundo, F. Viani, Y. Niu, and D. L. Douglass,Oxid. Met. 42, 465 (1994).

C. H. P. Lupis,Chemical Thermodynamics of Materials (North-Holland, New York, 1983).

R. Akila and K. T. Jacob,Ceram. Int. 14, 147 (1988).

O. Kubaschewski and E. U. Evans,Metallurgical Thermochemistry (Pergamon Press, New York, 1958).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Niu, Y., Gesmundo, F., Zeng, C. et al. The sulfidation of pure Co, Y, and of a Co-15 wt.% Y alloy in H2-H2S mixtures at 600–800°C. Oxid Met 48, 243–262 (1997). https://doi.org/10.1007/BF01670502

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01670502