Abstract

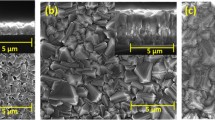

The effect of pressure during thermal plasma chemical vapor deposition of diamond films has been investigated for a pressure range from 100 to 760 Torr. The maximum growth rate in our experiments occurs at 270 Torr for substrate temperatures around 1000°C. The existence of an optimum pressure for diamond deposition may he related to the balance between generation and recombination of atomic hydrogen and carbon-containing active species in front of the substrate. To estimate the concentrations of atomic hydrogen and methyl radicals under thermal plasma conditions, calculations based on thermodynamic equilibrium have been performed. This approximate evaluation provides useful guidelines because rapid diffusion results in a near frozen chemistry within the boundary layer. The effect of substrate pretreatment on diamond deposition depends on the type of substrate used. Two growth modes have been observed-layer growth and island growth of diamond crystals on various substrates. Screw dislocations have been observed in diamond deposition in thermal plasmas, and defects such as secondary nucleations are more concentrated along (III) directions than along (100) directions.

Similar content being viewed by others

References

B. V. Spitsyn, L. L. Bouilov, and B. V. Derjaguin,J. Crystal Growth 52, 219 (1981).

K. E. Spear,J. Am. Ceram. Soc. 72, 171 (1989).

W. A. Yarbrough and R. Messier,Science 247, 688 (1990).

N. Fujimori and A. Hara, “Technological Application of CVD Diamond,”Proc. of the 1st Int. Symp. on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p. 14.

C. V. Deshpandey and R. F. Bunshah,J. Vac. Sci. Technol. A 7, 2294 (1989).

P. K. Bachmann and H. Lydtin, “Diamond Forming Discharges,”Mater. Res. Soc. Symp. Proc., Vol. 165, Characterization of Plasma-Enhanced CVD Processes, Materials Research Society, Pittsburgh, Pennsylvania, 1989, G. Lucovsky, D. E. Ibbotson, and D. W. Hess, eds. (1989), p. 181.

N. Ohtake and M. Yoshikawa,J. Electrochem. Soc. 137, 717 (1990).

K. Kurihara, K. Sasaki, M. Kawarada, and N. Koshino,Appl. Phys. Lett. 52, 437 (1988).

S. Matsumoto, “Deposition of Diamond from Thermal Plasma,”Diamond and Diamond-Like Materials Synthesis, MRS Extended Abstracts, Materials Research Society, Pittsburgh, Pennsylvania, 1988, G. H. Johnson, A. R. Badzian, and M. W. Geis, eds. (1988), p.119.

P. Klocek, J. Hoggins, P. Taborek, and T. Mckenna, “CVD Diamond by DC Plasma Torch,”SPIE Proceedings, Vol. 1325, Diamond Optics III, SPIE (the Int. Soc. for Optical Eng.), A. Feldman and S. Holly, eds. (1990), p.63.

Z. P. Lu, J. Heberlein, and E. Pfender,Plasma Chem. and Plasma Process 12, 35 (1991).

W. Zhu, R. Messier, and A. R. Badzian, “Effects of Process Parameters on CVD Diamond Films,”Int. Symp. on Diamond and Diamond-Like Films, The Electrochem. Soc., Pennington, New Jersey, 1989, J. P. Dismukes, A. J. Purdes, K. E. Spear, B. S. Meyerson, K. V. Ravi, T. D. Moustakas, and M. Yoder, eds. (1989), p.61.

Z. P. Lu, L. Stachowitz, P. Kong, J. Heberlein, and E. Pfender,Plasma Chem. Plasma Process. 11, 387 (1991).

T. M. Besmann, “SOLGASMIX-PV, a Computer Program to Calculate Equilibrium Relationships in Complex Chemical Systems,” Oak Ridge National Laboratory, Oak Ridge, Report ORNL/TM-5775, April 1977.

Z. P. Lu, T. W. Or, L. Stachowicz, J. Heberlein, and E. Pfender, “Diamond CVD in Thermal Plasmas,” presented in 1991 national meeting of Am. Soc. Mech. Eng., Minneapolis, July 28–31, 1991.

T. R. Anthony,Vacuum 41, 1356 (1990).

S. Iijima, Y. Aikawa, and K. Baba,Appl. Phys. Lett. 57, 2646 (1990).

S. C. Yu, H. S. Chun, and F. S. Guo,J. Crystal Growth 99, 1196 (1990).

P. K. Bachmann, H. Lydtin, D. U. Wiechert, J. J. Beulens, G. M. W. Kroesen, and D. C. Schram, “Diamond Deposition from a Cascaded Arc DC Plasma,”Proc. of the 3rd Int. Conf. on Surface Modification Technologies, Surface Modification Technologies III, The Mineral, Metals, and Materials Soc., Warrendale, Pennsylvania, T. S. Sudarshan and D. G. Bhat, eds. (1990), p. 69.

K. Reichelt and X. Jiang,Thin Solid Films 191, 91 (1990).

K. Kobashi, K. Nishimura, Y. Kawate, and T. Horiuchi,Phys. Rev. B: Condens. Matter. 38, 4067 (1988).

K. V. Ravi and A. Joshi,Appl. Phys. Lett. 58, 246 (1991).

C. Tsai, W. Gerberich, Z. P. Lu, J. Heberlein, and E. Pfender,J. Mater. Res. 6, 2127 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lu, Z.P., Heberlien, J. & Pfender, E. Process study of thermal plasma chemical vapor deposition of diamond, part II: Pressure dependence and effect of substrate pretreatment. Plasma Chem Plasma Process 12, 55–69 (1992). https://doi.org/10.1007/BF01447944

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01447944