Abstract

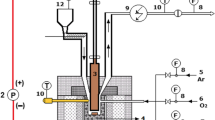

An electric arc melter used for waste treatment processing is numerically studied. The effects of different plasma working gases are studied by using a laboratory scale test reactor. A two-dimensional finite difference approximation is used to solve the set of governing equations. The Navier-Stokes equations coupled with the combined Maxwell's equation for the electromagnetic fields is used to obtain the temperature and flow fields in the are melter. It is found that the energy efficiency of the air plasma is lower than that of an argon plasma. However, the melted soil volumes are larger using the air plasma than those using the argon plasma. The overall energy efficiency increases cis the gap between the cathode and the soil surface decreases. More uniform gas temperatures are found for the air plasma than that for the argon plasma. Result obtained from the laboratory-scale are melter is used as an input of the energy absorbed into the soil for the USBM arc melter simulation. Results show a maximum temperature of 2195 K at the center of the heat generation and a molten soil exit temperature of 1600 K.

Similar content being viewed by others

References

L. L. Oden, W. K. O'Connor, P. C. Turner, N. R. Soelberg, and G. L. Anderson, Baseline Tests for Arc Melter Vitrification of INEL Buried Wastes, Volume I : Facility Description and Summary Data Report, EGG-WTD-10981, November 19, 1993.

K. C. Hsu and E. Pfender,J. Appl. Phys. 54, 3818 (1983).

M. C. Tsai and S. Kou,Int. J. Heat Mass Transfer 33, 2089 (1990).

E. Pfender,Pure Appl. Chem. 52, 1773 (1980).

J. J. Gonzalez, A. Gleizes, P. Proulx, and M. Boulos,J. Appl. Phys. 74, 3065 (1993).

K. Taniuchi,High Temp. Mater. Process. 11, 369 (1993).

S. Paik and H. D. Nguyen, “Numerical modeling of multiphase plasma soil flow and heat transfer in an electric arc furnace,” to appear inInt. J. Heat Mass Transfer.

P. C. Kong, J. D. Grandy, A. D. Watkins, T. L. Eddy, and G. L. Anderson, Bench-Scale Arc Melter for R&D in Thermal Treatment of Mixed Wastes, EGG-MS-10646, Idaho National Engineering Laboratory (INEL), Idaho Falls, Idaho, May 1993.

L. Gu, R. Jensen, A. E. Arntsberg, and J. A. Bakken, Study on Silicon Vapor Contaminated Argon Arcs and the Metal Pools, 11th International Symposium on Plasma Chemistry1, 222, Loughborough, England, Aug. 22 Aug. 27, 1993.

R. B. Bird, W. E. Stewart, and E. N. Lightfoot,Transport Phenomena, Wiley, New York (1960).

K. C. Hsu, “A self-consistent model for the high-intensity free-burning argon arc,” Ph.D Thesis, Dept. of Mech. Eng., Univ. of Minnesota, 1982.

I. P. Vandoormal and G. D. Raithby,Numer. Heat Transfer 7, 147 (1984).

S. V. Patankar,Numerical Heat Transfer and Fluid Flow, 1st edn., Hemisphere, New York (1980).

B. Basu and A. W. Date,Int. J. Hear Mass Transfer 33, 1149 (1990).

M. S. Engelman, FIDAP Manual, Version 7.0, Fluid Dynamics International, Evanston, Illinois (1993).

Seungho Paik, Y. P. Chyou, and E. Pfender, “Thermodynamic and transport properties: Ar, H2, N2, O2, Air, CO, CO2, H2O, H2/HCl,” under ALCOA Contract, Dept. of Mech. Eng., Univ. of Minnesota, 1987.

J. L. Buelt, V. F. FitzPatrick, C. L. Timmerman, J. G. Carter, and K. H. Oma, In Situ Vitrification of Transuranic Waste: An Updated Systems Evaluation and Applications Assessment, PNL-4800 suppl-1, US-70, March 1987.

J. B. Henderson and R. E. Taylor, Thermophysical Properties Research Laboratory, TPRL-1238, School of Mech. Eng., Purdue University, West Lafayette, Indiana, February (1993).

G. Anderson, private communication, April 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Paik, S., Hawkes, G. & Nguyen, H.D. Effect of working gases on thermal plasma waste treatment. Plasma Chem Plasma Process 15, 677–692 (1995). https://doi.org/10.1007/BF01447066

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01447066