Conclusions

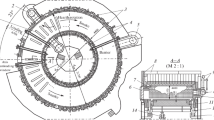

Investigations of the temperature field of the setting in a tunnel kiln of the high-alumina products section of the Zaporozhe Refractories Factory revealed individual features of the firing cycle for mullite-corundum articles; the low temperature of the setting in the first heated positions of the firing zone (Nos. 24–26) working without automatic regulation of the gas consumption according to the prescribed temperature of the kiln; the irregularity of the temperature field over the height and width of the setting; the variability of the linear dimensions and quality factors of the finished goods over the setting volume. Certain measures were worked out and used to eliminate these drawbacks.

We obtained the general relationship for developing temperature fields in settings in actual kilns present in the department making aluminous, fireclay, and magnesia goods: when ensuring that tkiln=const in the “leading” positions for burning the fuel in the firing zone we noted the extreme behavior of the temperature at the surfaces of the heated goods with a maximum at one or two positions.

On the basis of the analysis of the processes of heat and body exchange occurring in the tunnel kiln, we note methods for improving its heat work and also the quality of the goods.

Similar content being viewed by others

Literature cited

I. P. Davydov et al., Ogneupory, No. 7, 5–8 (1979).

S. I. Averin et al., Calculations for Heat Treatment Furnaces [in Russian], N. Yu. Taits (ed.), Kiev (1969).

I. G. Kharchenko et al., Ogneupory, No. 7, 14–18 (1974).

I. G. Kharchenko et al., in: Heat Engineering Principles for Controlling the Work in the Cooling Zone of Tunnel Kilns [in Russian], Abstracts from Repub. Conference: Problems of Heat Work in Metallurgical Furnaces, Dnepropetrovsk (1976), p. 9.

I. G. Kharchenko et al., Metallurg. Gornorud. Prom., No. 3, 57 (1979).

G. A. Tarakanchikov et al., Production of Refractories [in Russian], Tematich. Obtracl. Sb., No. 5, 67–80 (1976).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 5, pp. 15–20, May, 1981.

Rights and permissions

About this article

Cite this article

Kharchenko, I.G., Ivanov, V.I., Aryaev, V.V. et al. Temperature field in the setting of mullite corundum products in a tunnel kiln. Refractories 22, 253–258 (1981). https://doi.org/10.1007/BF01397980

Issue Date:

DOI: https://doi.org/10.1007/BF01397980