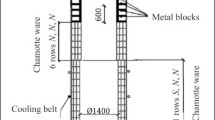

The final formation of the quality indicators of stone-cast samples occurs under heat treatment in heating furnaces comprising two tunnel kilns: a drying-calcining kiln for casting equipment preparation for pouring with liquid melt and a crystallization-tempering kiln for internal stress relief in the structure of castings. Six high-speed burners of the Vikhr 25 SV-5 type, inlet and outlet vestibules, gas extraction from the furnace, a heat exchanger for heating air for combustion, and an air duct system should be installed to facilitate the transition of an electric drying-calcining kiln to gas heating. In the crystallization zone, the arch height to 100 mm from the poured products with a uniform placement of electric heaters along the entire length of the zone should be reduced, and additional thermal insulation from fibrous tile materials with a thickness of at least 50 mm should be installed on the outer surface of the crystallization zone. In the annealing zone, cold air is supplied from a separate fan at a flow rate of up to 1400 m3/h at a pressure of at least 421.49 Pa through a transverse collector and eight distributed tuyeres with cutoff gates. While maintaining the quality of the products obtained, such a change in the complex design of tunnel kilns is accompanied by efficient heat utilization with the possibility of increasing thermal efficiency by 3.28 times, raising total energy consumption by 22.58%, and forming an additional volume of discharged gases of no more than 4000 m3/h with a temperature not exceeding 150°C.

Similar content being viewed by others

References

G. A. Lebedeva, G. P. Ozerova, “Stone casting as a rationally resistant material,” Stroit. Mater., No. 5, 14 – 15 (1998).

A. M. Ignatova, “Rules for managing the structure and properties of stone casting,” Vest. Perms. Nats. Issled. Politekhnich. Univ. Mashinostr., Materialoved., 12(3), 94 – 102 (2010).

V. V. Vagin, B. I. Pirogov, Stone casting [in Russian], GNTI ML, Moscow (1962).

A. S. Telegin, V. S. Shvydkiy, and Yu. G. Yaroshenko, Heat and Mass Transfer [in Russian], ed. Yu. G. Yaroshenko, IKC Akademkniga, Moscow (2002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 12 – 16, November, 2021.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Matyukhin, V.I., Fokin, S.N., Matyukhina, A.V. et al. Transfer Aspects of Electric Through-Type Furnaces for Heat Treatment of Stone-Cast Ware to Gas Heating. Refract Ind Ceram 62, 623–627 (2022). https://doi.org/10.1007/s11148-022-00653-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00653-5