Conclusions

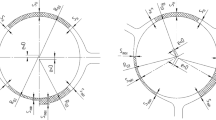

In developing designs of refractory-producing mills, one must try to achieve the smallest roller diameter and roller weight corresponding to the specified pressure and width of the roller on the mixture. An equation is given for determining the optimum diameter and weight of the rollers.

Similar content being viewed by others

Literature cited

A. K. Karklit, A. P. Larin, V. E. Vernikovskii, et al., The Production of Refractories by the Semidry Method [in Russian], Metallurgiya, Moscow (1972).

M. Ya. Sapozhnikov and I. A. Bulavin, Machines and Equipment for the Silicate Industry [in Russian], Promstroiizdat, Moscow (1950).

Ya. M. Pikovskii, Road Machines and Equipment [in Russian], Mashgiz, Moscow (1960).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 5, pp. 24–25, May, 1982.

Rights and permissions

About this article

Cite this article

Larin, A.P. Determining the dimensions of mixing mill rollers. Refractories 23, 233–234 (1982). https://doi.org/10.1007/BF01387347

Issue Date:

DOI: https://doi.org/10.1007/BF01387347