Conclusions

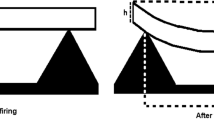

Automation of removal of freshly pressed dinas compacts from presses and stacking of them on furnace carts may be done only with a significant increase in the strength of the corners and edges of the compacts.

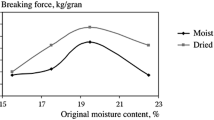

Sufficient strengthening of the angles and edges of freshly pressed dinas compacts may be provided with a short heat treatment for a moisture content of not more than 3%, even with the addition to the mixture of a normal production lime-iron mixture consisting of milk of lime (2.5% by CaO), iron-containing additions (0.8% by Fe2O3), and sulfite-yeast mash (0.8% by dry residue) and pressing of the compact to an apparent density of not less than 2.24 g/ cm3.

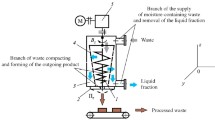

A short heat treatment of freshly pressed dinas compacts at a heat carrier temperature of not less than 150°C for strengtening of them is promising for mechanization and automation of transportation of the compacts from the presses and loading of them on the furnace carts.

Consideration of the question of the design and construction of an automated production line for the transportation of freshly pressed dinas compacts from the presses to the tunnel furnaces must be advanced from the stage of laboratory experiments to the stage of production testing.

The development and testing of the proposed variation of automation of transportation of freshly pressed dinas compacts from the presses and their heat treatment, stacking in the elements of the charge (columns), and placing on the furnace carts would, in addition to the reduction in labor costs, significantly reduce dust production in the press-dryer-tunnel furnace area.

Similar content being viewed by others

Literature cited

Yu. G. Chistov, I. A. Gol'dberg, V. Z. Shron, et al., Ogneupory, No. 4, 28–31 (1973).

V. S. Vasil'chenko, N. P. Kabashnyi, S. B. Éingori, et al., Ogneupory, No. 8, 17–20 (1975).

I. A. Gol'dberg, V. Z. Shron, Yu. G. Chistov, et al., Ogneupory, No. 1, 26–29 (1976).

A. A. Mukhin, A. A. Malyugin, and V. A. Zhitinev, Ogneupory, No. 6, 12–14 (1979).

N. E. Smirnyagin, Ogneupory, No. 9, 20–21 (1979).

I. S. Kainarskii, K. G. Romanchenko, and B. E. Pindrik, Ogneupory, No. 11, 521–526 (1958).

A. A. Bichurina, M. I. Kostomarov, and K. I. Safonova, Proceedings of the Eastern Institute of Refractories [in Russian], No. 6, Metallurgiya, Moscow (1966), pp. 135–143.

I. S. Kainarskii, Dinas [in Russian], Metallurgiya, Moscow (1961).

M. A. Shvartser, Ogneupory, No. 4–5, 22–23 (1945).

V. D. Tsigler, The Production of Dinas [in Russian], Gos. Nauch.-Tekh. Lit. Cher. Tsvet. Metallurgii, Moscow (1959).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 5, pp. 20–24, May, 1982.

Rights and permissions

About this article

Cite this article

Tsigler, V.D., Bulakh, V.L. & Romanenko, S.N. Strengthening freshly pressed dinas green compacts for the purpose of automating their transportation. Refractories 23, 228–232 (1982). https://doi.org/10.1007/BF01387346

Issue Date:

DOI: https://doi.org/10.1007/BF01387346