Abstract

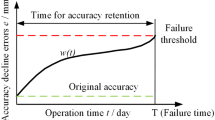

The susceptibility to crack resistance and warping and the uniformity of hardness distribution over the cross section of a part can be improved by controlling the direction and the degree of stirring of the cooling liquid in quenching. In the initial stage of quenching the cooling rate of the part should be high in order to obtain the requisite hardenability. When the core of the steel part is cooled to the temperature of the start of martensitic transformation (M 1), the cooling rate should be decreased. Stirring seems to be a principal method of affecting the cooling rate in quenching and can be an ideal means if it is possible to change the stirring rate in correspondence with the requisite conditions. At present, this can be achieved comparatively easily with the help of a computer-aided system for control of the time of submersion of parts in the quenching liquid (SCST). SCST are currently used by some plants in Korea. The article concerns the principles and use of SCST with the purpose of replacing oils by water-soluble polymer cooling liquids for quenching.

Similar content being viewed by others

References

G. E. Totten, S. E. Bates, and N. A. Clinton,Polymer Quenching Media, A Reference Book on Quenching Media and Technologies, Chap. 5, ASM International, Materials Park, Ohio (1993).

W. Luty, “Types of quenching media and their properties,” in: B. Liscic, H. M. Tensi, and W. Luty,Theory and Technology of Quenching, Chap 9, Springer Verlag, Berlin (1992).

S. E. Bates, G. E. Totten, and R. L. Brennan,Steel Hardening, A Reference Book on Heat Treatment, Vol. 4, ASM International, Materials Park, Ohio (1991), pp. 67–120.

G. E. Totten, M. E. Dakis, and L. M. Jarvis,Heat Treatment, 28–29, Dec. (1989).

R. K. Zhelokhovtseva,Steels in the USSR [in Russian], Issue 15, 238–239 (1985).

S. W. Han, S. G. Yan, and G. E. Totten, “Continuously changed stirring in quenching systems,” in:Warping Processes and Control in Quenching, ASM International, Materials Park, Ohio (1992), pp. 119–126.

S. G. Yan, S. W. Han, and G. E. Totten,Industrial Heating, 35–38, Jan. (1994).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 12–16, February, 1996.

Rights and permissions

About this article

Cite this article

Han, S.W., Sverdlin, A.V., Totten, G.E. et al. Systems for controlling the time of submersion of parts in a quenching liquid in periodic and continuous processes. Met Sci Heat Treat 38, 60–64 (1996). https://doi.org/10.1007/BF01362158

Issue Date:

DOI: https://doi.org/10.1007/BF01362158