Abstract

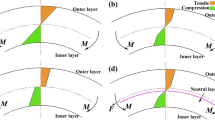

Spring back of the end surfaces of the billet and the elastic deflection of the dies in the process of hollow cylinder upsetting between elastic platens is investigated using a thermo-elastic-plastic coupling model. The finite-element method and the finite-difference method are adopted to simulate the forming process, and the unloading process is performed on the elements of the workpiece in response to the spring back phenomenon accounted for in this study. Therefore, the effect of die elasticity on the variation of the inner surface profile of the hollow cylinder, predictions of forging load, and the distributions of temperature and strain components may be examined. The surface asperity of the billet and the forging load obtained by simulation agree quite well with the results of the upsetting experiment.

Similar content being viewed by others

References

N. Rebelo and S. Kobayashi, “A coupled analysis of viscoplastic deformation and heat transfer-I”, International Journal of Mechanical Science, 22, pp. 699–705, 1980.

N. Rebelo and S. Kobayashi, “A coupled analysis of viscoplastic deformation and heat transfer-II”, International Journal of Mechanical Science, 22, pp. 707–718, 1980.

J. H. Argyris and J. St. Doltsinis, “On the natural formulation and analysis of large deformation coupled thermomechanical problems”, Computer Methods in Applied Mechanics and Engineering, 25, pp. 195–253, 1981.

O. C. Zienkiewicz, E. Onate and J. C. Heinrich, “A general formulation for coupled thermal flow of metals using finite elements”, Journal of Numerical Methods in Engineering, 17, pp. 1497–1514, 1981.

S. I. Oh, J. J. Park, S. Kobayashi and T. Altan, “Application of FEM modelling to simulate metal flow in forging a titanium alloy engine disk”, Journal of Engineering for Industry, 105, pp. 251–258, 1983.

J. Van Der Lugt and J. Huetink, “Thermal mechanically coupled finite element analysis in metal-forming processes”, Computer Methods in Applied Mechanical Engineering, 54, pp. 145–160, 1986.

O. Mahrenholtz, C. Westerling, W. Klie and N. L. Dung, “Finite element approach to large plastic deformation at elevated temperatures”, The Winter Annual Meetings of ASME, New Orleans, pp. 165–178, 1984.

J. Marten, C. Westerling, N. L. Dung and O. Mahrenholtz, “A coupled analysis of plastic deformation and heat transfer”, Proceedings of the Twenty-fifth International MTDR Conference, Birmingham, pp. 397–403, 1985.

T. Kato, M. Akai and Y. Tozawa, “Thermal analysis of cold upsetting”, Journal of Japanese Society Technology Plasticity, 28, pp. 791–798, 1987.

Z. C. Lin and S. Y. Lin, “An investigation of a coupled analysis of a thermoelastic-plastic model during warm upsetting”, International Journal of Machine Tools and Manufacture, 30, pp. 599–612, 1990.

F. Soavi, L. Tomesani and O. Zurla, “Incipient upsetting of solid cylinders between rigid and elastic tools”, International Journal of Mechanical Science, 36, pp. 601–615, 1994.

Y. Qin and R. Balendra, “FE simulation of the influence of die-elasticity on component dimensions in forward extrusion”, International Journal of Machine Tools and Manufacture, 37, pp. 183–192, 1997.

Y. Kojima and T. Mizuno, “A measurement of contact-pressure distributions in the upsetting of cylindrical billets”, JSME International Journal, Series I, 32, pp. 567–571, 1989.

L. Wang, Q. Cao and Z. Liu, “Numerical simulation and experimental verification of microstructure evolution in a 3-dimensional hot-upsetting process”, Journal of Materials Processing Technology, 58, pp. 331–336, 1996.

P. Tugcu, “Thermomechanical analysis of upsetting of a cylindrical billet”, Computers and Structures, 58, pp. 1–12, 1996.

Y. Yamada, Visco-elasticity Plasticity, Baifukan, Japan, 1980.

T. Shirakashi, K. Maekawa and E. Usui, “Flow stress of low carbon steel at high temperature and strain rate”, Bulletin Japan Society of Precision Engineering, 17, pp. 167–172, 1983.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, S.Y. Spring back phenomenon exhibited in the process of hollow cylinder upsetting. Int J Adv Manuf Technol 14, 466–473 (1998). https://doi.org/10.1007/BF01351392

Issue Date:

DOI: https://doi.org/10.1007/BF01351392