Conclusions

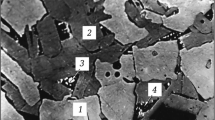

In the conditions of the experiments reported here, the materials are wetted by iron as soon as it melts. The wetting angle on corundum refractories is approximately half of that on spinel-based refractories.

Monoclinic zirconia added to the corundum or spinel reduces the wettability of the refractories by an iron melt at 1550°C. The wettability at 1550°C was lowest for a composition of 85% MgAl2O4+15% ZrO2 (θ=85°).

The wetting of the refractories concerned here by an aluminum melt begins at a temperature above 1100°C. The wettability by aluminum is lowest for corundum refractories containing added ZrO2. The degree of wetting by an aluminum melt of corundum containing up to 10 wt.% zirconia is lower than that of corundum alone.

The results of this investigation suggest that a refractory based on MgAl2O4 with 10 wt.% added ZrO2 can be recommended for the production of the proportioner inserts used in the continuous casting of steel of various grades. In casting killed steels, i. e., steels which are deoxidized with a larger amount of aluminum, proportioner inserts produced from corundum with 2–5 wt.% added ZrO2 can be expected to be sufficiently durable.

Similar content being viewed by others

Literature cited

N. V. Pitak and N. L. P'yanykh, Ogneupory, No. 5, 31–35 (1965).

S. I. Popel', in: The Theory and Practice of Foundry Work [in Russian], Mashgiz, Moscow (1959), pp. 162–187.

A. N. Novikov, in: The Physicochemical Fundamentals of Ceramics Production [in Russian], Gosstroiizdat, Moscow (1956), pp. 441–448.

J. R. Tinkplo and U. B. Krendalya, Cermets [Russian translation], IL, Moscow (1962).

Yu. V. Naidich and V. N. Eremenko, Zh. Neorgan. Khim.,4, No. 9, 2052–2057 (1959).

V. M. Amonenko, K. G. Romanchenko, and N. S. Tron', Stal', No. 11, 1002–1004 (1960).

A. M. Alper, R. N. McNally, R. N. Ribbe, et al., J. Am. Ceram. Soc.,45, No. 6, 203–207 (1962).

J. Brennau and J. Pask, J. Am. Ceram. Soc.,51, No. 10, 569–574 (1968).

W. D. Kingery, Kinetics of High-Temperature Processes, MIT Press (1959).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 12, pp. 41–45, December, 1976.

Rights and permissions

About this article

Cite this article

Kozlova, O.B., Suvorov, S.A. The wetting of refractories of the MgO-Al2O3-ZrO2 system with metal melts. Refractories 17, 763–767 (1976). https://doi.org/10.1007/BF01319887

Issue Date:

DOI: https://doi.org/10.1007/BF01319887