Abstract

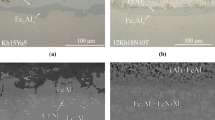

The results of a comparative research into the corrosion resistance of an aluminum matrix composite material produced by the oxygen lancing of a prehydrogenated aluminum alloy melt based on Al–Si–Fe with an iron content of over 1.0% and Al–7% Si alloy with an iron content of up to 0.3% modified by ligature 5Al–Ti for 2% are shown. The aluminum-alloy corrosion was conditioned by the film discontinuity of the oxide on some phases, primarily Al5SiFe. The composite and reference alloy-sample couples with a diameter of 15 mm and a length of 50 mm were put to the test in a 7% solution of NaCl salt fog in SFC-1 chamber on suspension brackets at a temperature of 22°C for 300 h. The results show the mass loss close values of the samples, despite the significantly higher iron content in the composite, because particles 100–200 nm in size formed in the melt by lancing are deposited on the composite phase boundaries, reducing the interaction surface area with the corrosive environment. The researched composite material can be recommended as a corrosion-resistant alternative to alloys with elevated iron content, which are used for high pressure die casting (HPDC).

Similar content being viewed by others

REFERENCES

Schuster, D.M., The world won’t beat a path to your door, Key Eng. Mater., 1992, vol. 77, pp. 337–348. http://www.scientific.net/KEM.77–78.337.

Chikova, O.A., Finkel’shtein, A.B., and Shefer, A.A., Structure and nanomechanical properties of the Al–Si–Fe alloy produced by blowing the melt with oxygen, Phys. Met. Metallogr., 2018, vol. 119, no. 7, pp. 685–690. https://doi.org/10.1134/S0031918X18070037

Pilling, N.B. and Bedworth, R.E., The oxidation of metals at high temperatures, J. Inst. Met., 1923, no. 29, pp. 529–582.

Ambat, R., Davenport, A.J., Scamans, G.M., and Afseth, A., Effect of iron-containing intermetallic particles on the corrosion behaviour of aluminium, Corros. Sci., 2006, vol. 48, no. 11, pp. 3455–3471. https://doi.org/10.1016/j.corsci.2006.01.00

Park, J.O., Paik, C.H., Huang, Y.H., and Alkire, R.C., Influence of Fe-rich intermetallic inclusions on pit initiation on aluminum alloys in aerated NaCl, J. Electrochem. Soc., 1999, vol. 146, no. 2, pp. 517–523. https://doi.org/S0013-4651(97)12-009-2

Nis, K., Davanger, K.Y., Strandmyr, O., and Holtan, H., Cathodic behavior of impure aluminum in aqueous media, J. Electrochem. Soc., 1981, vol. 128, no. 7, pp. 1523–1526. https://doi.org/10.1149/1.2127675

Zahavi, J., Zangvil, A., and Metzger, M., Structure and stability of anodic films formed on aluminum containing dispersed Al3Fe phase, J. Electrochem. Soc., 1978, vol. 125, no. 3, pp. 438–444. https://doi.org/10.1149/1.2131469

Seri, O., The effect of NaCl concentration on the corrosion behavior of aluminum containing iron, Corros. Sci., 1994, vol. 36, no. 10, pp. 1789–1803. https://doi.org/10.1016/0010-938X(94)90132-5

Samuel, A.M., Samuel, F.H., and Doty, H.W., Observations on the formation of β-Al5FeSi phase in 319 type Al–Si alloys, J. Mater. Sci., 1996, vol. 31, no. 20, pp. 5529–5539. https://doi.org/10.1007/BF01159327

Mulazimoglu, M.H., Zaluska, A., Gruzleski, J.E., and Paray, F., Electron microscope study of Al–Fe–Si intermetallics in 6201 aluminum alloy, Metal. Mater. Trans. A, 1996, vol. 27, no. 4, pp. 929–936. https://doi.org/10.1007/BF02649760

Syvertsen, M., Oxide skin strength on molten aluminum, Metal. Mater. Trans. B, 2006, vol. 37, no. 3, pp. 495–504. https://doi.org/10.1007/s11663-006-0033-8

ASTM B85/B85M-18e1. Standard specification for aluminum—alloy die castings. https://www.astm.org/ Standards/B85.htm. Accessed 2018.

Lucas, K.A. and Clarke, H., Corrosion of Aluminium-Based Metal Matrix Composites, Baldock: Research Studies Press, 1993.

Nielssen, H., Hufnagel, W., and Ganoulis, G., Aluminium—Taschenbuch, Düsseldorf: Aluminium-Verlag GmbH, 1974.

Foley, R.T., Localized corrosion of aluminum alloys—a review, Corrosion, 1986, vol. 42, no. 5, pp. 277–288.

Sobolev, A., Wolicki, I., Kossenko, A., Zinigrad, M., and Borodianskiy, K., Coating formation on Ti–6Al–4V alloy by micro arc oxidation in molten salt, Materials, 2018, vol. 11, no. 9, pp. 1611–1619. https://doi.org/10.3390/ma11091611

Wen, L., Wang, Y., Zhou, Y., Guo, L., and Ouyang, J.H., Microstructure and corrosion resistance of modified 2024 Al alloy using surface mechanical attrition treatment combined with microarc oxidation process, Corros. Sci., 2011, vol. 53, no. 1, pp. 473–480. https://doi.org/10.1016/j.corsci.2010.09.061

Wei, T., Yan, F., and Tian, J., Characterization and wear–and corrosion–resistance of microarc oxidation ceramic coatings on aluminum alloy, J. Alloys Compd., 2005, vol. 389, nos. 1–2, pp. 169–176. https://doi.org/10.1016/j.jallcom.2004.05.084

Rao, K.P., Ram, G.J., and Stucker, B.E., Improvement in corrosion resistance of friction stir welded aluminum alloys with micro arc oxidation coatings, Scr. Mater., 2008, vol. 58, no. 11, pp. 998–1001.

Uludağ, M., Kocabaş, M., Dışpınar, D., Çetin, R., and Cansever, N., Effect of Sr and Ti addition on the corrosion behaviour of Al–7Si–0.3Mg alloy, Arch. Foundry Eng., 2017, vol. 17, no. 2, pp. 125–130. https://doi.org/10.1515/afe-2017-0063

ASTM B117–18. Standard practice for operating salt spray (fog) apparatus. https://www.astm.org/Standards/B117.htm. Accessed 2018. https://doi.org/10.1520/B0117-18

De Salazar, J.M.G., Urena, A., Manzanedo, S., and Barrena, M.I., Corrosion behaviour of AA6061 and AA7005 reinforced with Al2O3 particles in aerated 3.5% chloride solutions: potentiodynamic measurements and microstructure evaluation, Corros. Sci., 1998, vol. 41, no. 3, pp. 529–545. https://doi.org/10.1016/S0010-938X(98)00135-8

Acevedo-Hurtado, P.O. and Sundaram, P.A., Corrosion behavior of novel Al-Al2O3 composites in aerated 3.5% chloride solution, J. Mater. Eng. Perf., 2017, vol. 26, no. 1, pp. 69–75. https://doi.org/10.1007/s11665-016-2420-x

Sherif, E.S.M., Almajid, A.A., Latif, F.H., and Junaedi, H., Effects of graphite on the corrosion behavior of aluminum-graphite composite in sodium chloride solutions, Int. J. Electrochem. Sci., 2011, vol. 6, pp. 1085–1099.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare to have no conflict of interest.

Additional information

Translated by K. Gumerov

About this article

Cite this article

Finkelstein, A.B., Shak, A.V. & Schaefer, A.A. Corrosion of an Aluminum Matrix Composite in situ Based on Al–7Si–1Fe Alloy. Russ. J. Non-ferrous Metals 61, 108–111 (2020). https://doi.org/10.3103/S1067821220010046

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220010046